Dec . 28, 2024 08:21 Back to list

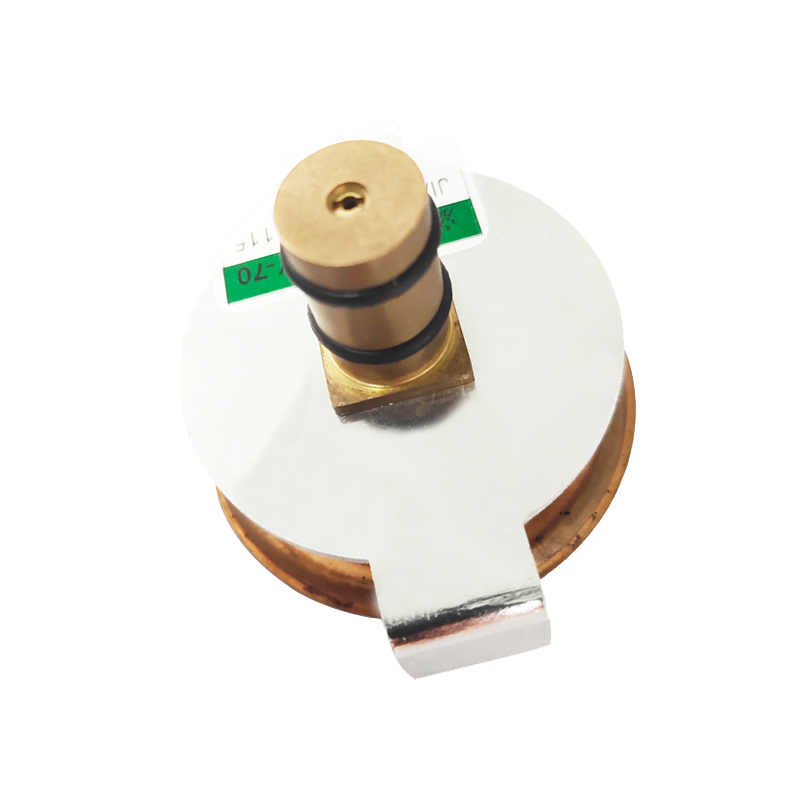

low pressure diaphragm pressure gauges product

Understanding Low Pressure Diaphragm Pressure Gauges

In various industrial applications, accurate and reliable measurement of pressure is crucial. Among the tools used for this purpose, low pressure diaphragm pressure gauges stand out due to their effectiveness in measuring low-pressure ranges, typically below 30 psi (2 bar). This article explores how these gauges work, their construction, applications, and advantages.

What is a Diaphragm Pressure Gauge?

Diaphragm pressure gauges are designed to measure pressure by employing a flexible membrane or diaphragm. This diaphragm is subject to pressure changes from the fluid or gas within a system. The key aspect of a low-pressure diaphragm gauge is its ability to function effectively in low-pressure environments without sacrificing accuracy.

How They Work

When pressure is applied to the side of the diaphragm, it deforms. This deformation is transferred to a mechanism, usually a pointer or digital sensor, that translates the diaphragm's movement into a readable measurement on the gauge dial. The gauge's sensitivity is defined by the materials and construction of the diaphragm, allowing it to detect subtle changes in pressure.

Construction

Low pressure diaphragm pressure gauges are typically constructed with robust materials such as stainless steel, brass, or a combination of metals that resist corrosion and wear. The diaphragm itself is often made of thin metal or elastomeric materials, which maintains its flexibility and responsiveness under varying pressure conditions. Gauges may also feature various connection types, such as threaded or flanged connections, for easy integration into piping systems.

Applications

Low pressure diaphragm gauges are widely used in various industries, including

low pressure diaphragm pressure gauges product

2. Food and Beverage Industry They monitor pressure in processes such as fermentation and bottling where maintaining specific low-pressure conditions is critical.

3. Pharmaceutical Manufacturing Low pressure gauges are used in the production processes that require precise control over pressure to ensure product safety and regulatory compliance.

4. Oil and Gas In drilling operations and refining processes, low pressure measurements help track system integrity and prevent hazardous leaks.

5. Environmental Monitoring Diaphragm gauges are also used in wastewater management systems to monitor pressure levels in treatment plants.

Advantages

One of the main advantages of low pressure diaphragm pressure gauges is their precision. They provide accurate readings even at low pressure levels, where other types of gauges may fail to perform effectively. Their robust construction means they can withstand corrosive environments and mechanical wear, leading to a longer lifespan and reduced maintenance costs.

Additionally, diaphragm gauges are relatively easy to install and calibrate, making them a preferred choice in various applications. Their ability to provide quick response times to pressure changes allows for dynamic monitoring, which is essential in processes where pressure fluctuations are common.

Conclusion

Low pressure diaphragm pressure gauges are indispensable tools in environments where pressure measurement is critical. Their ability to accurately measure low pressures, robust design, and versatility make them suitable for a wide range of industrial applications. As industries continue to seek efficient and reliable monitoring solutions, diaphragm pressure gauges will undoubtedly play a vital role in ensuring operational efficiency and safety.

These gauges not only enhance our ability to measure and control pressure but also contribute to the overall integrity and performance of industrial systems. Choosing the right low pressure diaphragm gauge for specific applications can greatly affect the efficiency and reliability of an operation, ensuring that industries can maintain control over their processes and enhance productivity.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025