Sep . 09, 2024 11:08 Back to list

low pressure diaphragm pressure gauges manufacturer

Understanding Low Pressure Diaphragm Pressure Gauges A Comprehensive Overview

Low pressure diaphragm pressure gauges are essential instruments widely used in various industries to measure and monitor low pressure levels accurately. These gauges operate on the principle of a flexible diaphragm that responds to changes in pressure. As the pressure varies, the diaphragm bends, which translates into a readable measurement.

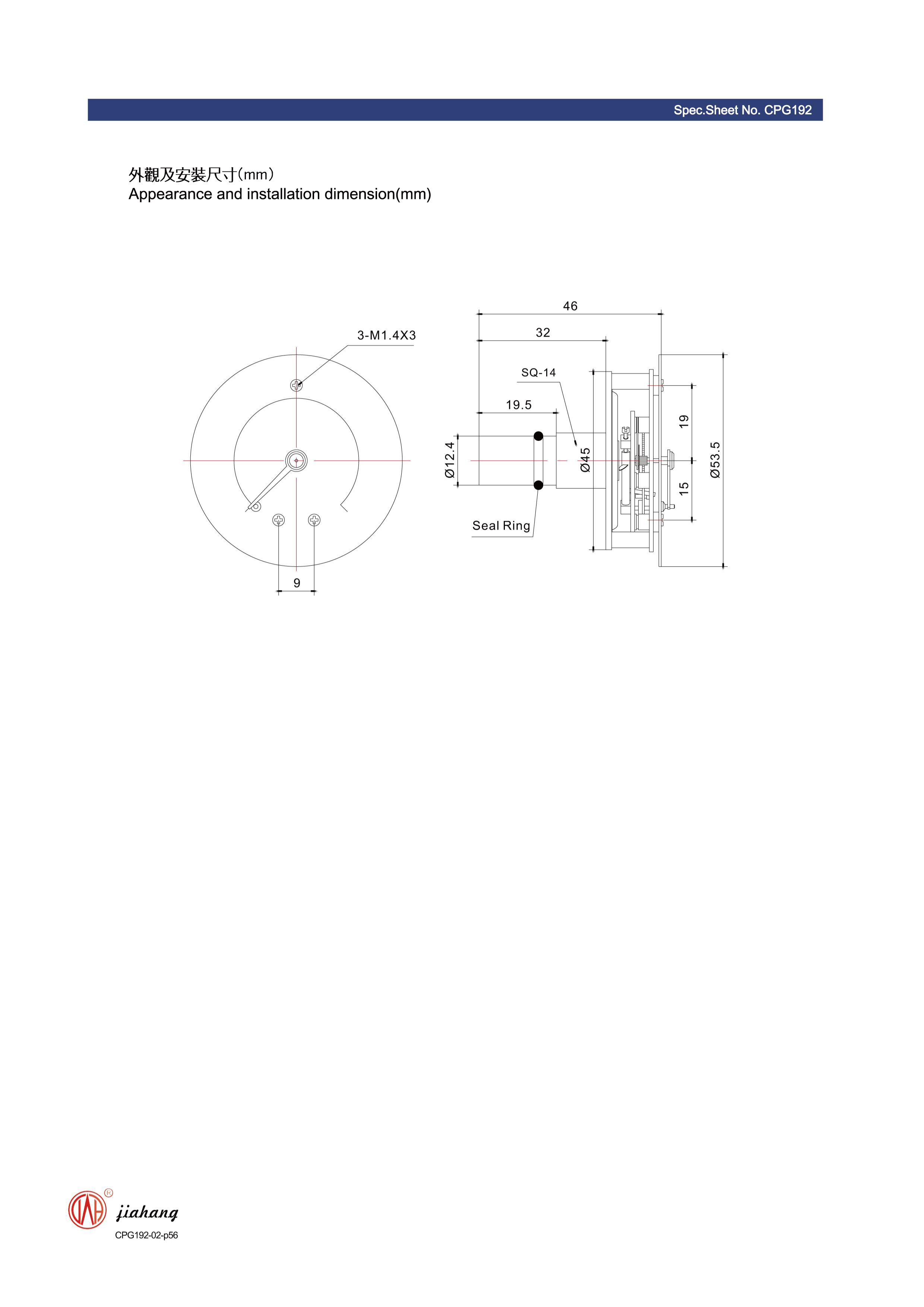

The construction of a low pressure diaphragm gauge typically involves a diaphragm made from materials like stainless steel, rubber, or other elastomers. This diaphragm is housed within a casing that is designed to withstand environmental conditions, ensuring durability and reliability. The design is crucial, as it directly affects the response time and accuracy of the pressure measurements.

Low pressure applications can be found in numerous settings such as HVAC systems, gas pipelines, and process industries. The ability to monitor low pressure levels is vital for maintaining system efficiency and safety. For instance, in HVAC systems, maintaining the correct pressure ensures optimal performance and comfort. Similarly, in gas pipelines, monitoring low pressure helps prevent leaks and potential hazards.

low pressure diaphragm pressure gauges manufacturer

One of the primary advantages of low pressure diaphragm gauges is their sensitivity. Unlike traditional pressure gauges, which may be designed for higher pressure readings, diaphragm gauges can detect minute changes in pressure, making them ideal for low-pressure environments. This sensitivity allows for fine-tuning and adjustments in processes that require precise pressure control.

Manufacturers of low pressure diaphragm gauges focus on several key features to enhance their products. Accuracy is paramount; hence, many gauges undergo rigorous calibration processes. Additionally, manufacturers often incorporate features such as dual scales, allowing users to read pressure in different units easily. Some gauges are also equipped with features like integrated electronic outputs, enabling direct connection to control systems for real-time monitoring.

When selecting a low pressure diaphragm pressure gauge, it is essential to consider factors like the maximum pressure rating, operating temperature, and compatibility with the media being measured. Furthermore, the choice of material for the diaphragm is crucial, especially in scenarios where corrosive substances are involved.

In conclusion, low pressure diaphragm pressure gauges play a critical role in various industrial applications by providing accurate pressure readings in low-pressure scenarios. The combination of sensitivity, reliability, and durability makes them indispensable tools for engineers and technicians. As technology advances, manufacturers are continually enhancing these gauges, incorporating smarter features and better materials to meet the evolving needs of industries. For companies looking for precision and safety in their operations, investing in high-quality low pressure diaphragm pressure gauges is a step toward achieving optimal performance and reliability.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025