Nov . 03, 2024 03:35 Back to list

liquid filled diaphragm pressure gauge jah

The Liquid-Filled Diaphragm Pressure Gauge A Comprehensive Overview

Pressure measurement is essential in various industrial applications, ensuring that systems operate safely and efficiently. Among the myriad instruments available, the liquid-filled diaphragm pressure gauge stands out due to its accuracy, durability, and ability to function in challenging environments.

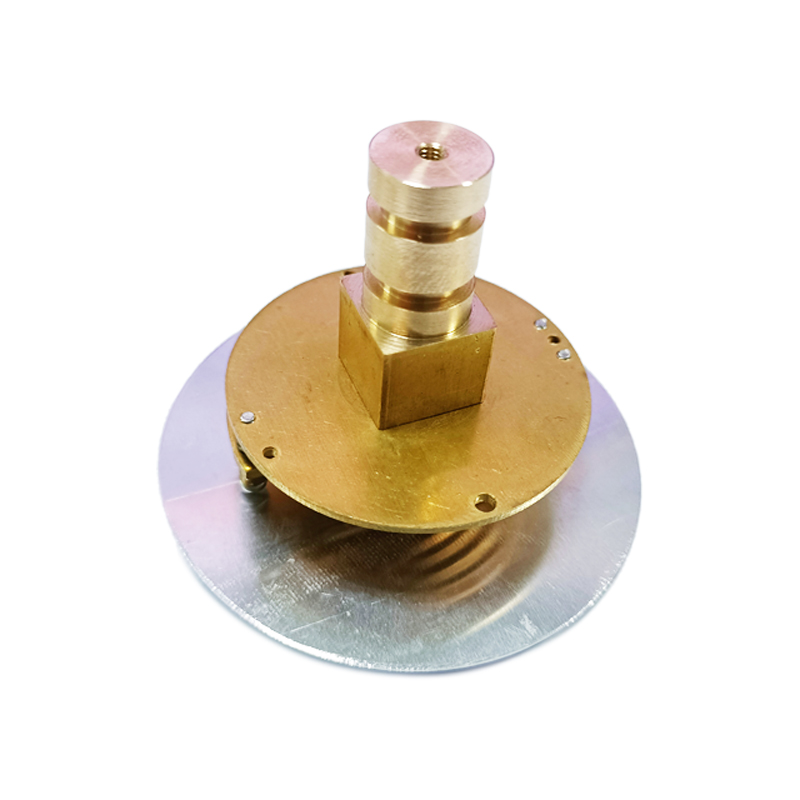

A liquid-filled diaphragm pressure gauge comprises a sealed metal casing filled with a non-corrosive liquid—typically glycerin or silicone oil. The primary function of this liquid is to dampen vibrations and pulsations, which often affect the accuracy of standard pressure gauges. In environments where pressure fluctuations are common, the fluid-filled design provides a significant advantage by stabilizing the needle movement and enhancing readability.

The diaphragm, typically made from stainless steel, acts as the sensing element. When pressure is applied, the diaphragm flexes, causing a movement that is transmitted to a pointer indicating the pressure reading on the dial. This mechanism allows for high sensitivity, making liquid-filled diaphragm gauges capable of measuring a wide range of pressures accurately.

liquid filled diaphragm pressure gauge jah

One of the most notable benefits of liquid-filled gauges is their ability to withstand harsh operating conditions. In extreme temperatures and environments with dust, moisture, or corrosive substances, the liquid filling acts as a protective barrier, prolonging the gauge's lifespan. Additionally, the viscosity of the liquid helps to absorb shock loads, thereby reducing wear on the mechanical components.

Another significant advantage lies in user experience. The liquid-filled design minimizes the effects of vibration and shock, allowing operators to read the dial easily without the needle jumping around. This feature is crucial in industries like oil and gas, water treatment, and pharmaceuticals, where precision is paramount.

However, it is essential to consider some limitations when using liquid-filled diaphragm pressure gauges. Over time, the liquid can evaporate or leak, particularly if the gauge is subjected to high temperatures or improper installation. Regular maintenance checks are essential to ensure that the gauge remains in optimal condition.

In conclusion, liquid-filled diaphragm pressure gauges are indispensable tools in various industrial settings, offering accurate pressure measurement and enhanced durability. As industries continue to evolve and demand greater precision, the relevance of these gauges remains steadfast. Investing in a reliable liquid-filled diaphragm gauge not only improves operational efficiency but also ensures safety in high-risk environments. For any application requiring dependable pressure monitoring, these gauges are undoubtedly a wise choice.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025