Dec . 05, 2024 15:17 Back to list

liquid filled diaphragm pressure gauge factories

Understanding Liquid-Filled Diaphragm Pressure Gauges A Comprehensive Overview

Pressure measurement is a critical aspect across numerous industrial applications, and choosing the right type of pressure gauge can significantly impact the efficiency and accuracy of operations. One popular option is the liquid-filled diaphragm pressure gauge, which excels in various environments and offers unique advantages over its dry counterparts. This article explores the features, benefits, and applications of liquid-filled diaphragm pressure gauges, while also highlighting the role of factories in manufacturing these essential instruments.

The Structure of Liquid-Filled Diaphragm Pressure Gauges

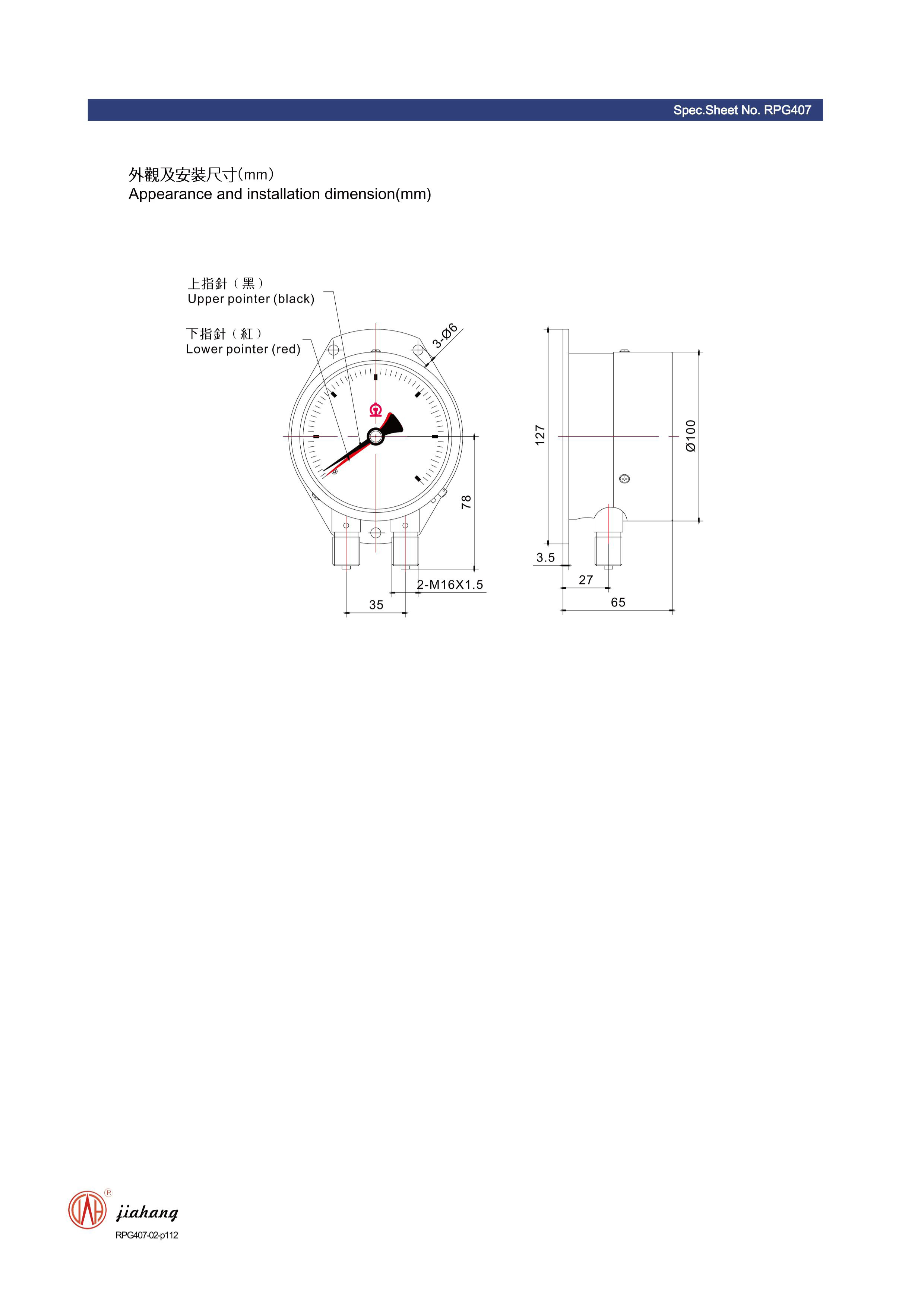

Liquid-filled diaphragm pressure gauges comprise several key components, including a diaphragm, a pressure chamber, and a liquid fill (typically glycerin or silicone oil). The diaphragm, usually made of metal, responds to changes in pressure by deflecting. This movement is transmitted through a system of gears and levers to provide a reading on the dial. The liquid fill serves multiple purposes it dampens vibrations and pulsations, protects the internal components from corrosive gases or liquids, and enhances the visibility of the reading by creating a steady and smooth pointer movement.

Advantages of Liquid-Filled Gauges

1. Damping of Fluctuations One of the primary benefits of liquid-filled gauges is their ability to dampen pressure fluctuations caused by pulsating pressure sources, which is common in many industrial processes. The liquid fill absorbs the shocks and allows for more stable readings, making these gauges ideal for dynamic systems.

2. Protection Against Corrosion In environments where the pressure source can lead to corrosion, the liquid filling protects the internal mechanisms of the gauge. This is particularly advantageous in chemical processing industries where aggressive materials may be handled.

3. Enhanced Durability Liquid-filled gauges tend to be more robust and can endure harsh conditions better than dry gauges. The fluid fill reduces wear on the moving parts, thus extending the lifespan of the instrument.

4. Improved Readability The presence of liquid in the gauge can provide clearer readings by minimizing pointer jitter and enhancing visibility in challenging lighting conditions. This can significantly improve operator experience and reduce the likelihood of errors.

liquid filled diaphragm pressure gauge factories

Applications in Various Industries

Liquid-filled diaphragm pressure gauges are used in a range of industries, from oil and gas to food and beverage. In the oil and gas sector, these gauges monitor the pressure of pipelines, ensuring smooth and safe operations. In food and beverage manufacturing, they help regulate pressure in processes like carbonation, ensuring product quality. Additionally, they find application in HVAC systems, water treatment facilities, and medical equipment, demonstrating their versatility across diverse sectors.

Manufacturing Process and Quality Assurance

The production of liquid-filled diaphragm pressure gauges is a meticulous process that requires advanced technology and strict quality control. Factories specializing in these gauges must ensure that each component—from the diaphragm material to the liquid fill—is manufactured to meet industry standards. Common materials used include stainless steel for the diaphragm and high-grade glycerin or silicone oil for the fill.

During manufacturing, gauges undergo rigorous testing to ensure accuracy and reliability. Calibration is performed under various pressure conditions to guarantee operational performance in real-world scenarios. Furthermore, factories implement quality assurance protocols to detect any defects or discrepancies before the gauges are dispatched.

Conclusion

Liquid-filled diaphragm pressure gauges play an essential role in ensuring precise pressure measurement across various industries. Their unique design and functionality provide significant advantages, including vibration dampening, corrosion protection, and enhanced readability. As technology continues to evolve, the standards for manufacturing these instruments remain high, with dedicated factories focused on quality and performance. By choosing liquid-filled diaphragm pressure gauges, industries can enhance operational efficiency, improve safety, and maintain the integrity of their processes.

Understanding these gauges and their manufacturing processes is crucial for anyone involved in pressure measurement, ensuring the selection of the right instrument for specific applications.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025