Sep . 04, 2024 06:36 Back to list

liquid filled differential pressure gauge manufacturer

Understanding Liquid-Filled Differential Pressure Gauges A Comprehensive Overview

In industrial applications, accurate pressure measurement is crucial for ensuring the safety and efficiency of various processes. Among the instruments used for this purpose, liquid-filled differential pressure gauges play a significant role. These gauges are designed to measure the difference in pressure between two points in a system and are particularly beneficial in environments where mechanical vibrations and temperature fluctuations can compromise the accuracy of standard gauges.

What Are Liquid-Filled Differential Pressure Gauges?

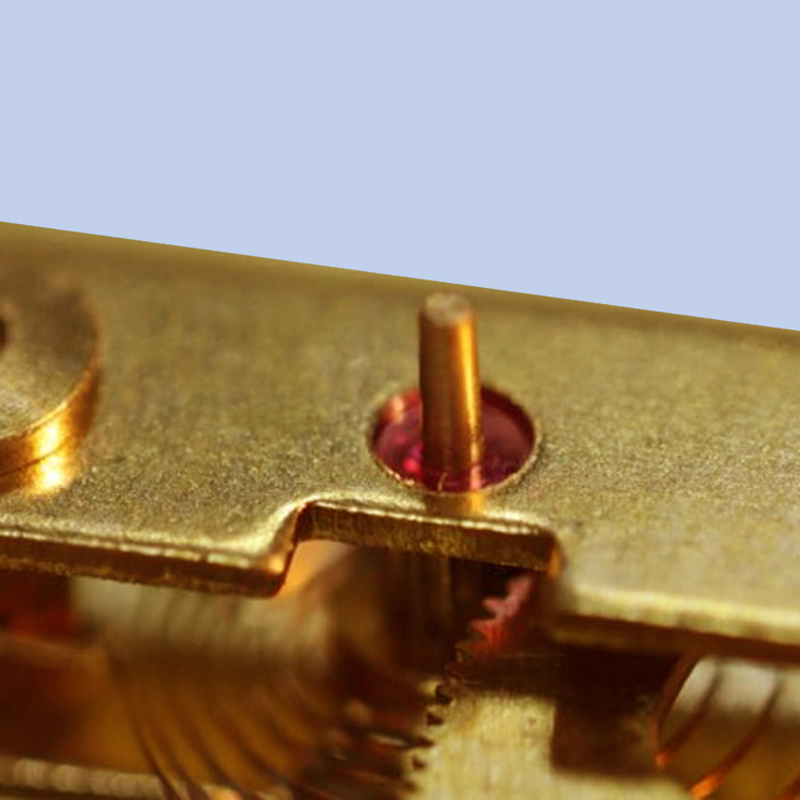

Liquid-filled differential pressure gauges are specialized devices filled with a liquid, typically glycerin or silicone oil, which acts as a dampening agent. The liquid fills the internal components of the gauge, including the Bourdon tube, which is the primary sensing element. This innovative design helps mitigate the effects of shock and vibration, ensuring that the gauge provides stable and reliable readings.

The main function of these gauges is to measure the pressure difference between two points, such as upstream and downstream in a filtration system, or in a process where flow rates need to be monitored. By understanding the pressure differential, operators can determine the condition of filters, valves, and other components in the system.

Advantages of Liquid-Filled Gauges

1. Improved Accuracy The liquid filling dampens the mechanical oscillations caused by vibrations, allowing for more accurate readings. This is especially important in dynamic environments where pressure changes rapidly.

2. Extended Lifespan Because they are less susceptible to wear and tear due to mechanical shock, liquid-filled gauges often have a longer service life compared to their dry counterparts. This durability translates to lower replacement costs and reduced maintenance requirements over time.

liquid filled differential pressure gauge manufacturer

3. Temperature Compensation The liquid helps to moderate temperature fluctuations, providing more consistent readings in varying conditions. This feature is essential for processes that operate over a range of temperatures.

4. Corrosion Resistance Many liquid-filled gauges are designed to withstand corrosive environments, as the liquid filling can provide additional protection to internal components.

Manufacturers and Applications

Several manufacturers specialize in producing high-quality liquid-filled differential pressure gauges, offering a range of models to suit different applications. These gauges are commonly used in industries such as oil and gas, water treatment, pharmaceuticals, and food processing, where precision and reliability are non-negotiable.

When selecting a liquid-filled differential pressure gauge, it is crucial to consider factors such as the pressure range, material compatibility, and the specific environmental conditions in which the gauge will operate. Working closely with a reputable manufacturer can ensure that you find the right gauge that meets your operational needs.

Conclusion

Liquid-filled differential pressure gauges are indispensable tools in a variety of industrial settings. Their design, which incorporates liquid to enhance performance and durability, addresses many of the challenges faced by traditional pressure measurement devices. As technology continues to evolve, these gauges will likely become even more sophisticated, further improving accuracy and reliability in critical applications. For industries that depend on precise pressure measurements, investing in a high-quality liquid-filled gauge is not just beneficial; it is essential.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025