Oct . 31, 2024 19:57 Back to list

High Pressure Differential Gauge for Industrial Applications and Precision Measurement Solutions

Understanding the JAH High-Pressure Differential Pressure Gauge

In various industrial applications, the measurement of pressure is critical for ensuring the safe and efficient operation of equipment and processes. Among the tools used in this domain, the JAH high-pressure differential pressure gauge stands out due to its robust design, high accuracy, and reliability in demanding environments. This article delves into the features, applications, and advantages of using a JAH high-pressure differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points within a system. It is an essential instrument for applications where pressure fluctuations can affect the performance of processes or equipment. The gauge provides a quick and accurate reading of pressure differences, which is foundational in maintaining operational efficiency and safety.

Features of JAH High-Pressure Differential Pressure Gauge

The JAH high-pressure differential pressure gauge is known for its advanced engineering and reliability. Key features include

1. High Accuracy The gauge is designed for precision, ensuring that readings are accurate even under high-pressure conditions. This is crucial for applications involving fluids in critical systems.

2. Robust Construction Made from high-quality materials, the JAH gauge withstands extreme environmental conditions. Its durable design is suitable for both indoor and outdoor installations.

3. Wide Operating Range The gauge can measure a broad range of pressures, accommodating various industrial needs, from water and oil to gas and steam applications.

4. User-Friendly Design With clear markings and easy-to-read dials, the JAH gauge allows for quick interpretation of pressure readings, reducing downtime and enhancing efficiency during monitoring.

Applications

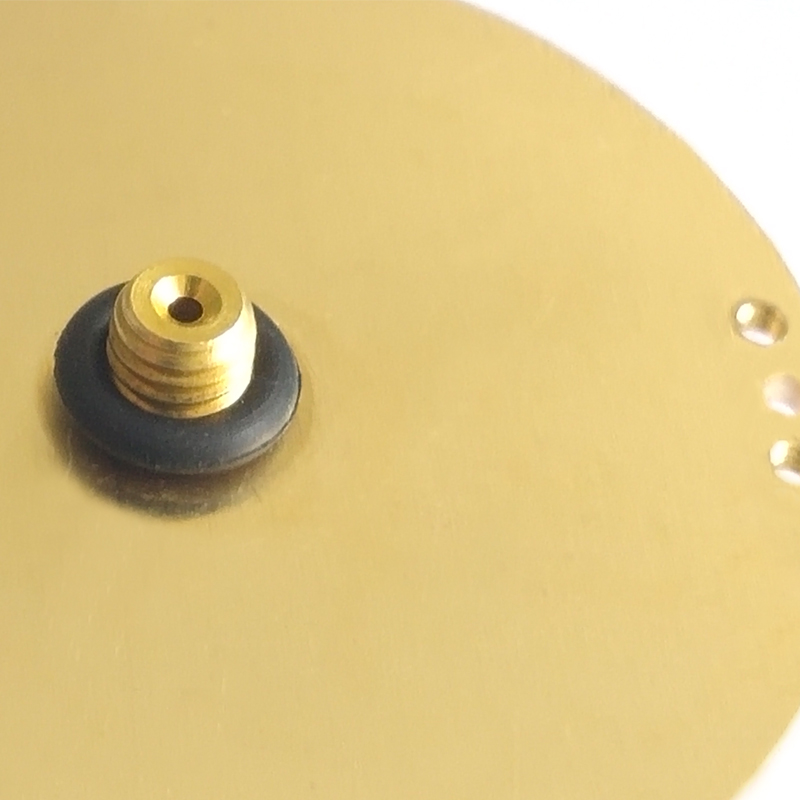

jah high pressure differential pressure gauge

The JAH high-pressure differential pressure gauge finds application across numerous industries, including

- Oil and Gas Monitoring pressure differences in drilling, refining, and transport helps optimize production and ensure safety.

- Chemical Processing Used for monitoring reactions and material transfers, the gauge ensures that processes remain within safe pressure limits.

- HVAC Systems In heating, ventilation, and air conditioning systems, the gauge helps manage air flow and pressure to maintain indoor air quality and comfort.

- Water Treatment The gauge aids in monitoring pressure in filtration systems, ensuring that water quality meets safety standards.

Advantages

Using a JAH high-pressure differential pressure gauge offers several advantages

- Enhanced Safety By providing reliable pressure readings, the gauge helps prevent dangerous over-pressurization situations.

- Increased Efficiency Accurate measurements enable better process control, leading to improved operational performance.

- Cost-Effective The durability and reliability of the JAH gauge reduce maintenance needs and associated costs over time.

In conclusion, the JAH high-pressure differential pressure gauge is an indispensable instrument in various industries where pressure measurement is crucial. Its features, ranging from high accuracy to robust construction, make it a reliable choice for maintaining safety and operational efficiency. As industries continue to evolve, the importance of such reliable measurement instruments will only grow, solidifying the role of tools like the JAH gauge in achieving success in complex systems.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025