Dec . 23, 2024 07:42 Back to list

JAH Fire Pump Discharge Pressure Monitoring and Management System Guide

Understanding the Importance of Fire Pump Discharge Pressure Gauges

In fire protection systems, the fire pump plays a critical role in ensuring that water is delivered effectively to combat fires. Central to the operation of a fire pump is the discharge pressure gauge, which is essential for monitoring the pump's performance and the effectiveness of the firefighting system as a whole. This article delves into the significance, functionality, and maintenance of fire pump discharge pressure gauges.

Significance of Discharge Pressure Gauges

Discharge pressure gauges are vital instruments in any fire protection system. They provide real-time readings of the pressure being delivered by the fire pump to the piping system. This information is crucial for several reasons

1. Safety Monitoring discharge pressure helps ensure that the fire suppression system is operating within safe limits. Excessive pressure can damage the piping and sprinkler systems, leading to potential failures during a fire event.

2. Performance Assessment Regular monitoring of the pressure gauge allows facility managers to assess the performance of the fire pump. Sudden changes in discharge pressure can indicate issues such as pump cavitation, blockages in the piping, or worn-out components, which require immediate attention.

3. Compliance Many jurisdictions have regulations that require fire protection systems to be tested at specific intervals. The discharge pressure gauge provides essential data needed for compliance with these safety codes and standards.

How Discharge Pressure Gauges Work

Typically, a fire pump discharge pressure gauge is installed near the discharge port of the pump. It consists of a Bourdon tube or diaphragm that reacts to the pressure of the water exiting the pump. As water flows through the gauge, the mechanical element inside the gauge bends or expands, which moves a needle on a dial to indicate the pressure level.

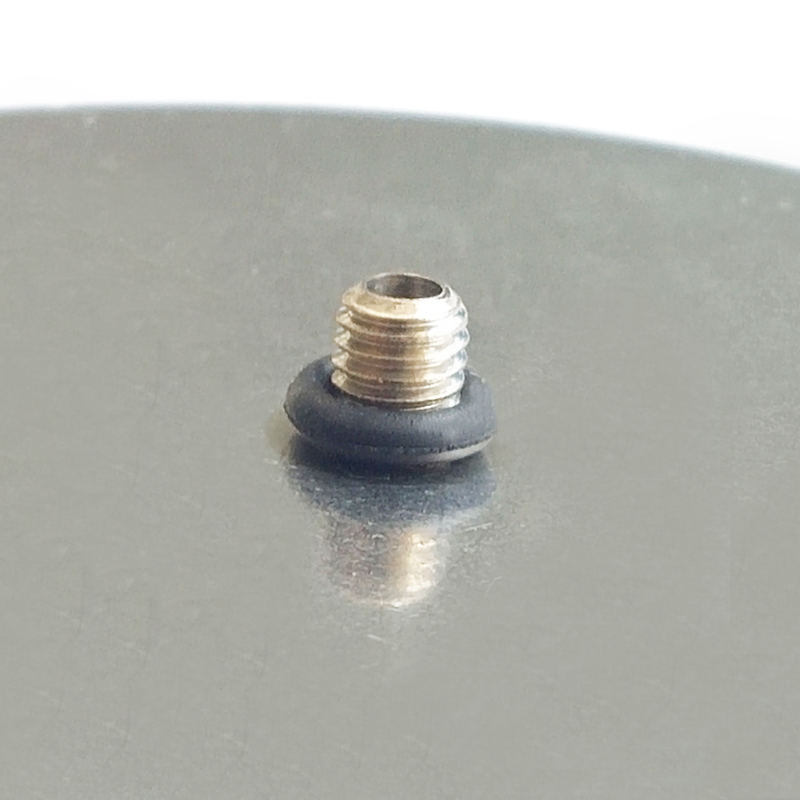

jah fire pump discharge pressure gauge

The gauge is calibrated to provide readings typically in pounds per square inch (PSI) or kilopascals (kPa). A properly functioning gauge will provide accurate readings, allowing operators to make informed decisions during an emergency.

Maintenance of Discharge Pressure Gauges

To ensure that discharge pressure gauges provide reliable readings, regular maintenance is essential. Here are some key maintenance tips

1. Periodic Calibration Just like any measuring instrument, discharge pressure gauges can drift out of calibration over time. It is crucial to have them calibrated regularly by a certified technician to ensure accuracy.

2. Visual Inspections Routine visual inspections should be performed to check for signs of physical damage, rust, or leaks. Any visible issues should be addressed immediately, as they can compromise the gauge's function.

3. System Testing During fire pump testing, operators should pay close attention to the discharge pressure readings. Fluctuations or erratic readings may indicate underlying problems with the system that need prompt investigation.

4. Documentation Keep a log of all maintenance activities, inspections, and calibrations related to the discharge pressure gauge. This documentation helps in tracking the performance of the fire protection system over time and facilitates compliance with inspection requirements.

Conclusion

Fire pump discharge pressure gauges are indispensable in the realm of fire safety. By providing critical information about pump performance and system integrity, these gauges contribute to the effectiveness of fire protection systems and the safety of occupants. Regular maintenance and monitoring of these gauges not only comply with safety regulations but also enhance the overall reliability of fire suppression efforts. As the dynamic nature of fire protection evolves, understanding and caring for every component, including the discharge pressure gauge, remains paramount.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025