Oct . 15, 2024 20:13 Back to list

JAH Diaphragm Vacuum Pressure Gauge for Accurate Measurement and Monitoring

Understanding the JAH Diaphragm Vacuum Pressure Gauge A Comprehensive Overview

Vacuum pressure gauges play an essential role in various industries, particularly in fields such as manufacturing, scientific research, and environmental monitoring. One particularly noteworthy type of vacuum pressure gauge is the diaphragm vacuum pressure gauge, exemplified by devices produced by leading manufacturers like JAH. These gauges are designed to measure low pressures and vacuum levels with precision, making them indispensable in numerous applications. This article delves into the workings, advantages, and applications of the JAH diaphragm vacuum pressure gauge.

What is a Diaphragm Vacuum Pressure Gauge?

A diaphragm vacuum pressure gauge utilizes a flexible diaphragm to measure pressure variations within a vacuum environment. The diaphragm, typically made from materials such as metal or elastomers, responds to pressure changes by deflecting. This deflection is then translated into a readable measurement of the vacuum pressure. JAH’s diaphragm vacuum pressure gauge is recognized for its reliability and accuracy, ensuring that users receive the most precise data regarding their vacuum systems.

How Does it Work?

The functioning of a JAH diaphragm vacuum pressure gauge involves several components working in tandem. When the pressure inside the gauge decreases (indicating a vacuum), the external atmospheric pressure pushes against the diaphragm. This differential pressure causes the diaphragm to flex inward. The degree of flexing is proportional to the amount of pressure inside the gauge, which can then be calibrated to give a specific pressure reading.

The diaphragm is connected to a mechanical linkage or electronic sensor, which translates the movement of the diaphragm into a readable format. This can be displayed on an analog scale or a digital readout, depending on the model of the gauge. The simplicity of the design combined with the effectiveness of the diaphragm makes these gauges some of the most reliable on the market.

Advantages of JAH Diaphragm Vacuum Pressure Gauges

1. High Accuracy and Precision One of the standout features of the JAH diaphragm vacuum pressure gauge is its accuracy. These gauges can measure a wide range of pressures, often down to the millitorr range, providing vital data for processes that require utmost precision.

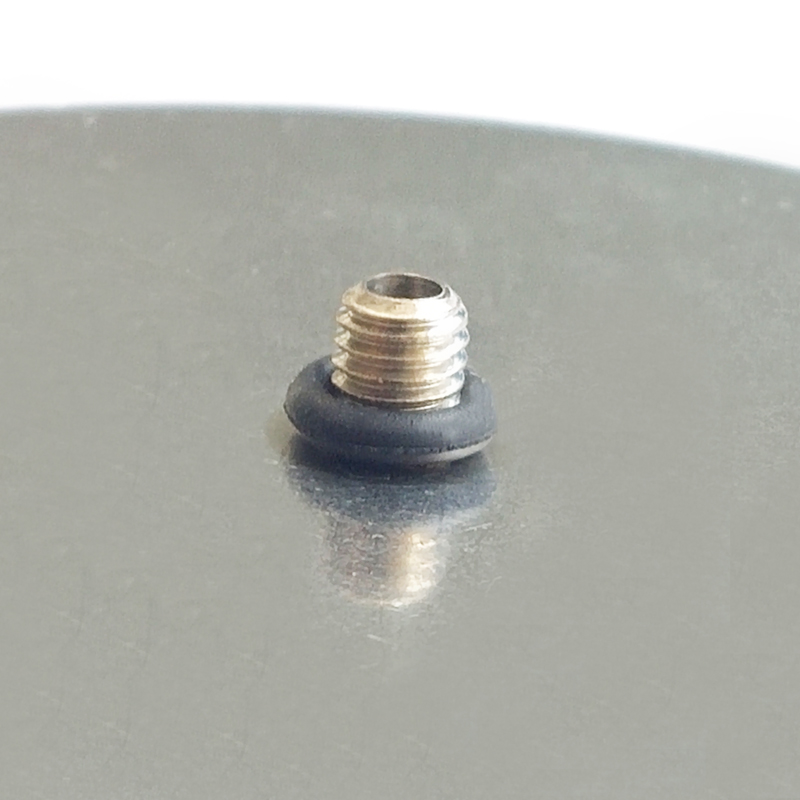

jah diaphragm vacuum pressure gauge

2. Robust Construction JAH gauges are constructed to withstand challenging industrial environments. The materials used in their construction not only contribute to durability but also limit wear and tear, ensuring a long service life.

3. Wide Application Range With their ability to function in various pressure environments, JAH diaphragm vacuum pressure gauges can be employed across multiple sectors, including pharmaceuticals, food processing, and research institutions.

4. Ease of Use Many users appreciate the straightforward functionality of these gauges. They require minimal training to operate, allowing for quick and effective integration into existing systems.

Applications of JAH Diaphragm Vacuum Pressure Gauges

The applications for JAH diaphragm vacuum pressure gauges are vast. In the pharmaceutical industry, precise vacuum control during processes such as freeze-drying is crucial. The gauges ensure that the pressure is maintained at optimal levels, facilitating the quality of the end product. Similarly, in the food processing sector, these gauges are used to monitor vacuum packaging systems, ensuring food safety and extending shelf life.

Additionally, research laboratories utilize diaphragm vacuum gauges for experiments that require vacuum conditions. Whether in material science, chemistry, or physics, these gauges provide researchers with accurate pressure readings, leading to reliable experimental outcomes.

Conclusion

In conclusion, JAH diaphragm vacuum pressure gauges are a vital component in modern industrial and scientific applications. Their ability to provide accurate and reliable vacuum measurements makes them an indispensable tool in various sectors. With advantages such as robustness, ease of use, and versatility in application, it is no wonder that these gauges are a preferred choice among professionals. As technology continues to evolve, the demand for precise measurement tools like the JAH diaphragm vacuum pressure gauge will undoubtedly grow, keeping pace with the advancing needs of various industries. Understanding their functionality, advantages, and applications can guide businesses in making informed decisions about incorporating these essential tools into their operations. In a world where measurement precision is paramount, the JAH diaphragm vacuum pressure gauge stands out as a trusted solution.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025