Nov . 16, 2024 06:11 Back to list

jah bourdon differential pressure gauge

Understanding the Jah Bourdon Differential Pressure Gauge

The Jah Bourdon differential pressure gauge is an essential instrument widely used in various industries for measuring the difference in pressure between two points in a system. The design of this gauge is based on the Bourdon tube principle, which has been a reliable technology for measuring pressure for over a century. In this article, we will explore the working mechanism, applications, advantages, and limitations of the Jah Bourdon differential pressure gauge.

Working Mechanism

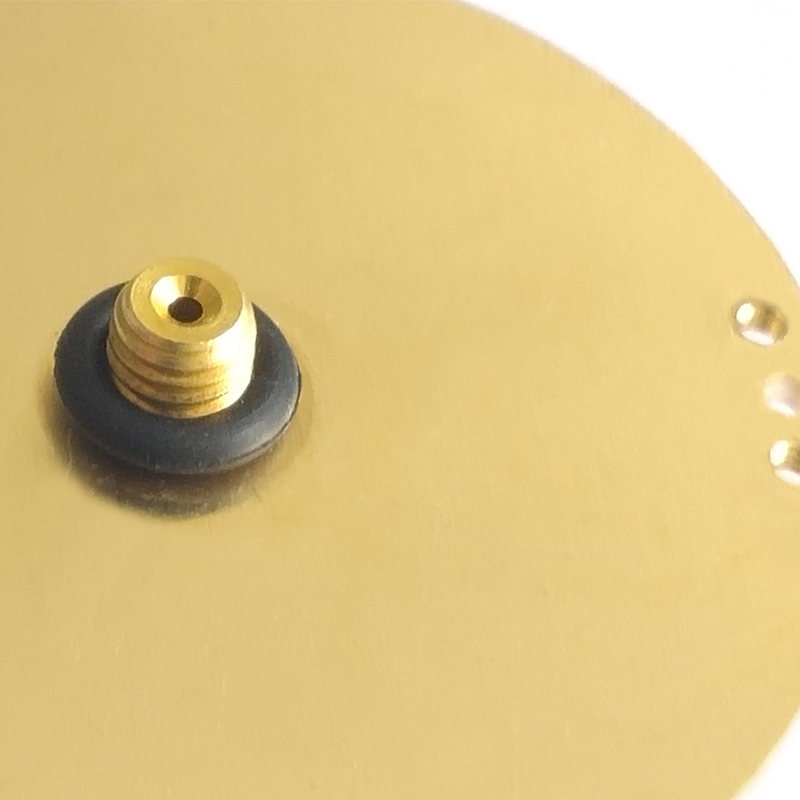

The Jah Bourdon differential pressure gauge operates by utilizing a Bourdon tube, a curved, elastically deformable metal tube. When pressure is applied, the tube tends to straighten out due to the elastic properties of the material. In a differential pressure gauge, two Bourdon tubes are typically used, one for each pressure input. The difference in pressure causes a relative deformation between the two tubes.

The displacement of the tubes is transmitted through a gear mechanism to a pointer that moves across a calibrated dial. The dial is marked to show the pressure differential, allowing operators to read the pressure difference easily. This straightforward yet effective design ensures high accuracy and reliability.

Applications

Jah Bourdon differential pressure gauges find applications in numerous sectors, including

1. Oil and Gas Industry These gauges monitor pressure differences in pipelines and tanks, ensuring safe and efficient operation by preventing leaks and bursts.

2. Water Treatment Plants They are crucial in gauging pressure differentials across filters and membranes, helping operators maintain optimal performance.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor pressure drop across filters and coils, enabling effective maintenance and energy efficiency.

4. Pharmaceutical and Chemical Industries Accurate pressure monitoring is essential for maintaining product quality and safety in processes that involve volatile substances.

5. Power Generation In power plants, these gauges are used to monitor pressure differences in steam and water systems, ensuring proper functioning of the turbines and cooling systems.

Advantages

jah bourdon differential pressure gauge

The Jah Bourdon differential pressure gauge offers several benefits

- High Accuracy The mechanical design of the Bourdon tube provides precise measurements, making it suitable for critical applications.

- Durability Built from robust materials, these gauges can withstand harsh environments, including extreme temperatures and pressures.

- Low Maintenance Unlike electronic pressure sensors, Bourdon gauges require minimal maintenance, leading to lower operational costs.

- Simple Installation The gauges are easy to install and use, saving time during setup.

Limitations

Despite its advantages, the Jah Bourdon differential pressure gauge has some limitations

- Temperature Sensitivity Extreme temperatures can affect the accuracy of the readings, as thermal expansion may cause deviations in measurements.

- Non-linearity At very high pressures, the relationship between the pressure differential and the movement of the Bourdon tube may become non-linear, which can complicate calibration.

- Mechanical Wear Over time, the mechanical components may wear out, which can lead to inaccuracies if not regularly checked or calibrated.

Conclusion

The Jah Bourdon differential pressure gauge remains a vital instrument in various industries, providing reliable pressure measurements critical for safety and efficiency. Despite some limitations, its durability, accuracy, and low maintenance needs make it a favored choice among engineers and operators. As technology continues to evolve, traditional mechanical gauges like the Jah Bourdon provide a tried-and-tested method for monitoring pressure differentials, ensuring that industries can operate effectively and safely. Whether it's in monitoring oil pipelines or ensuring proper airflow in HVAC systems, the significance of the Jah Bourdon differential pressure gauge is undeniable.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025