Oct . 20, 2024 15:13 Back to list

isolation diaphragm pressure gauge suppliers

Understanding Isolation Diaphragm Pressure Gauges and Choosing the Right Suppliers

In various industrial applications, pressure measurement is crucial for ensuring the safety and efficiency of processes. One of the highly effective tools used for this purpose is the isolation diaphragm pressure gauge. This specialized gauge is designed to handle the challenges posed by high-pressure fluid environments, especially those that are corrosive, viscous, or contain solid particles. As industries continue to evolve and demand more precise pressure monitoring, it’s essential to identify reliable suppliers of isolation diaphragm pressure gauges.

What is an Isolation Diaphragm Pressure Gauge?

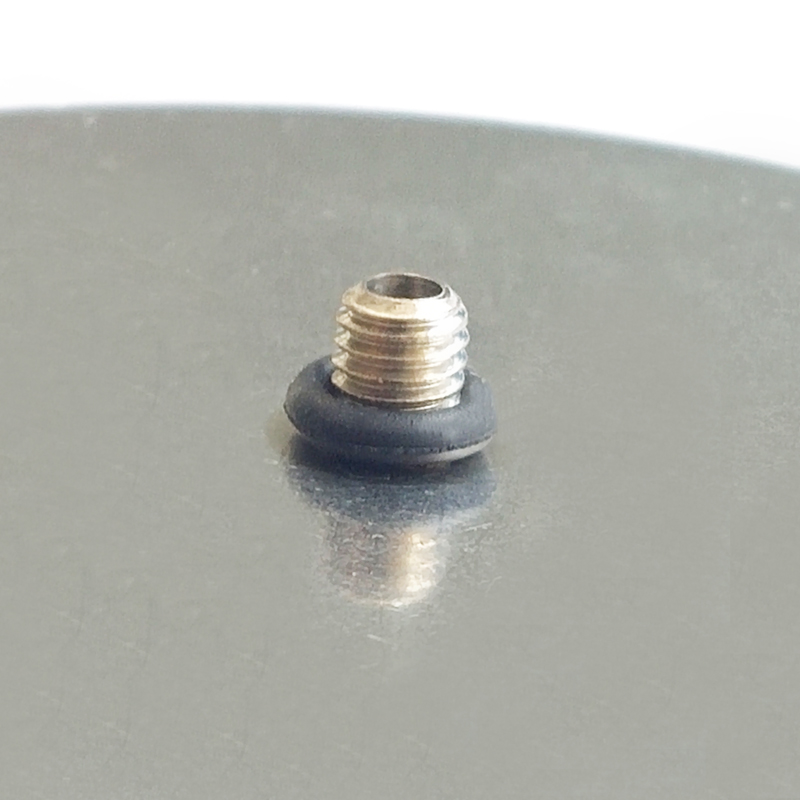

An isolation diaphragm pressure gauge is a device that measures pressure by using a diaphragm—essentially, a flexible membrane. This membrane is subjected to the pressure of the contained fluid, which causes it to deflect. The degree of deflection is then calibrated to produce an accurate reading of the pressure within the system. The diaphragm isolates the measuring mechanism from the process fluid, providing protection against potentially damaging effects.

This type of gauge is particularly beneficial in corrosive environments due to its ability to minimize direct contact with the process media. Additionally, it is ideal for applications involving slurries or fluids with suspended solids, where traditional pressure gauges might become clogged or damaged.

Applications of Isolation Diaphragm Pressure Gauges

These pressure gauges can be found across multiple industries, including

1. Chemical Processing Isolation diaphragm gauges protect the measurement elements from aggressive chemicals, preventing corrosion and ensuring longevity. 2. Oil and Gas In this industry, these gauges monitor fluid pressure in pipelines where hydrocarbons are transported, requiring robustness to handle hazardous materials. 3. Food and Beverage Sanitary designs of isolation diaphragm pressure gauges are critical for maintaining hygiene standards while accurately monitoring pressure in production processes. 4. Pharmaceuticals Compliance with strict regulations necessitates the use of reliable gauges that can withstand sterilization processes.

Choosing the Right Supplier

isolation diaphragm pressure gauge suppliers

Selecting a credible supplier for isolation diaphragm pressure gauges is essential to ensure quality and performance. Here are several factors to consider in your search

1. Reputation and Experience Research the supplier’s reputation in the market. Long-established companies often have extensive expertise and a proven track record in providing reliable products. Look for customer reviews and testimonials to gauge satisfaction levels.

2. Quality Assurance Ensure that the supplier adheres to strict quality control measures. Certifications such as ISO 9001 can indicate a commitment to maintaining high standards in manufacturing processes.

3. Product Range Different applications require different specifications. A good supplier should offer a variety of diaphragm gauges with various materials, sizes, and pressure ratings to cater to your specific needs.

4. Technical Support Reliable suppliers often provide excellent customer service, including technical support to help you choose the right product and guidance on installation and maintenance. This support is vital for troubleshooting and ensuring correct usage.

5. Pricing and Warranty While price should not be the sole determining factor, it is essential to compare pricing among various suppliers. Additionally, check for warranties or guarantees, which can further assure the quality of the gauges.

6. Lead Times and Delivery Options Effective supply chain management is important in today’s fast-paced industrial environment. Look for suppliers that can offer rapid turnaround times on orders and flexible delivery options.

Conclusion

Isolation diaphragm pressure gauges play a pivotal role in safeguarding processes across various industries by providing accurate pressure readings in challenging environments. Identifying the right supplier is essential for obtaining high-quality equipment that meets the specific requirements of your application. By focusing on supplier reputation, product quality, customer support, and other essential factors, businesses can successfully invest in reliable pressure measurement solutions that enhance operational efficiency and safety. As industries continue to grow and evolve, the demand for these specialized gauges is expected to rise, making the role of competent suppliers even more vital.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025