Nov . 08, 2024 13:21 Back to list

Innovative Solutions for Measuring Sanitary Differential Pressure with Advanced Gauge Technologies

Understanding Sanitary Differential Pressure Gauge Products

In today's fast-paced industrial landscape, maintaining safety and efficiency in processes is of utmost importance. One of the key components in ensuring optimal functioning, especially in sanitary environments, is the use of differential pressure gauges. These instruments are crucial for monitoring pressure differences in various applications, including food and beverage production, pharmaceuticals, and water treatment. This article delves into the significance, functionality, and applications of sanitary differential pressure gauge products.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points within a system. Unlike standard pressure gauges, which measure absolute pressure, differential pressure gauges provide the ability to analyze variations that can indicate changes in system performance or detect faults. In sanitary applications, maintaining strict controls over pressure is essential to ensure product quality, safety, and compliance with regulatory standards.

Importance of Sanitary Design

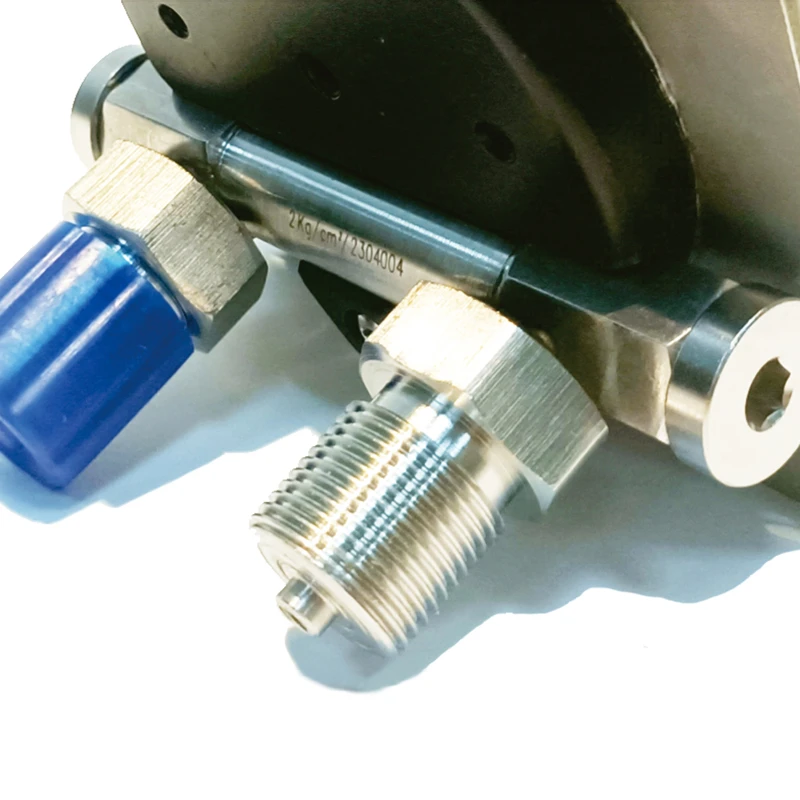

Sanitary differential pressure gauges are specifically designed to meet the stringent requirements of industries that prioritize hygiene and cleanliness. These gauges are often constructed from high-grade materials like stainless steel, which not only offer durability but also resist corrosion and contamination. Their design minimizes the risk of bacterial growth, making them ideal for environments where sanitary conditions are paramount.

Key features of these sanitary gauges include smooth surfaces, sanitary fittings, and the ability to withstand high-temperature sterilization processes. Moreover, many of these instruments come with certifications from organizations such as the FDA or 3A, ensuring that they meet the necessary hygiene standards for use in sensitive applications.

How Do Sanitary Differential Pressure Gauges Work?

Sanitary differential pressure gauges work by measuring pressure differences across a variety of components such as filters, pumps, and flow systems. The primary function is to detect any variations in pressure that could indicate blockages, leaks, or other issues that might compromise system efficiency.

sanitary differential pressure gauge products

When the differential pressure reaches a pre-set limit, the gauge can trigger alarms or initiate system responses, helping operators to take corrective actions promptly

. This proactive approach not only aids in maintaining product quality but also in preventing costly downtime, thus embracing efficiency in operations.Applications Across Industries

Sanitary differential pressure gauges find applications in numerous sectors, each requiring stringent adherence to safety and quality. In the food and beverage industry, these gauges are crucial for monitoring filtration systems, ensuring that products meet health and safety standards. In pharmaceutical manufacturing, they aid in maintaining cleanroom conditions, where even minute variations in pressure could lead to contamination.

Additionally, in water treatment facilities, these gauges help monitor the pressure across different stages of filtration, ensuring the delivery of safe and clean water. They are equally relevant in clean dairy processing plants, breweries, and biopharmaceutical production, where pressure monitoring assists in maintaining integrity and compliance.

The Future of Sanitary Pressure Gauges

As industries continue to adopt advanced technologies, the future of sanitary differential pressure gauges looks promising. With the integration of smart technology and IoT (Internet of Things), these gauges can now provide real-time data analytics, enhancing monitoring and operational efficiency. This innovation not only allows for remote monitoring but also supports predictive maintenance, thereby reducing operational costs and increasing system reliability.

Moreover, advancements in sensor technology offer increased accuracy and responsiveness, further solidifying the role of sanitary differential pressure gauges in modern industrial practices.

Conclusion

Sanitary differential pressure gauges are essential instruments that play a significant role in ensuring safe and efficient operations across various industries. Their unique design and reliability in measuring pressure differentials make them indispensable in environments where purity and safety are critical. As technology evolves, these gauges will continue to enhance their capabilities, offering even greater efficiency, reliability, and insights for industries aiming to maintain high-quality standards while minimizing operational risks. As a result, investing in high-quality sanitary differential pressure gauge products is not just a necessity but a strategic advantage for modern-day industrial operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025