Dec . 13, 2024 21:01 Back to list

Premium Quality Diaphragm Pressure Gauge for Accurate Measurements and Reliability

Understanding High-Quality Wika Diaphragm Pressure Gauges

In modern industrial applications, precision and reliability in measuring pressure are paramount. One of the most trusted names in the field of pressure measurement is Wika, a company renowned for its high-quality diaphragm pressure gauges. These devices play a pivotal role in various sectors, including chemical processing, oil and gas, food and beverage, and pharmaceuticals, among others. In this article, we will explore the features, benefits, and applications of high-quality Wika diaphragm pressure gauges.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge utilizes a flexible diaphragm to measure pressure. When pressure is applied, the diaphragm deforms, and this movement is translated into a readable value on the gauge. This design is especially advantageous for measuring pressure in corrosive, viscous, or high-particle-content media, which can often damage traditional Bourdon tube gauges.

Features of Wika Diaphragm Pressure Gauges

Wika diaphragm pressure gauges are engineered with a variety of high-quality materials, ensuring durability and accuracy. Some notable features include

1. Robust Construction Wika gauges are crafted from stainless steel or other resistant materials, providing excellent protection against corrosion and extreme environmental conditions.

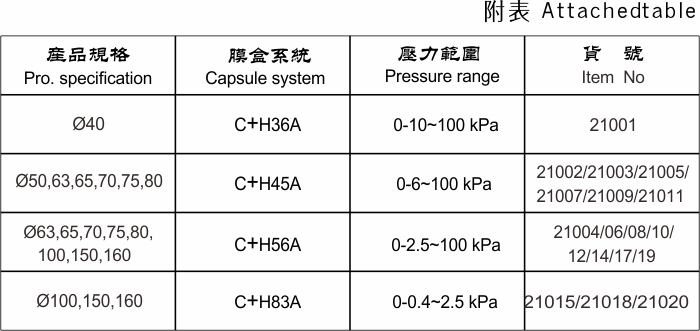

2. Variety of Sizes and Scales Wika offers a range of gauges in different sizes and measuring scales, allowing customers to choose the most suitable option for their specific applications.

3. High Accuracy Precision is a hallmark of Wika products. These gauges typically provide accuracy levels of ±1% or better, ensuring that users get reliable readings.

4. Innovative Design Many Wika gauges incorporate advanced design features, such as overload protection and liquid filling, which enhance their performance in challenging environments.

5. Versatility Wika diaphragm pressure gauges can measure both absolute and differential pressures, making them suitable for an array of applications.

high quality wika diaphragm pressure gauge

Benefits of Using Wika Diaphragm Pressure Gauges

Using high-quality Wika diaphragm pressure gauges offers numerous advantages

- Long Service Life The robust construction and quality materials significantly extend the operational lifespan of these gauges, resulting in lower replacement costs over time.

- Easy Maintenance Many Wika gauges are designed for easy disassembly and cleaning, minimizing downtime and maintenance costs.

- Enhanced Safety By using diaphragm gauges, industries can ensure safer operations, particularly when dealing with hazardous or aggressive media. The closed design reduces the risk of leaks compared to traditional gauges.

- Accurate Monitoring Consistent and precise pressure readings are crucial for maintaining operational efficiency and safety standards. Wika gauges provide the reliability needed for critical measurements.

Applications of Wika Diaphragm Pressure Gauges

Given their exceptional properties, Wika diaphragm pressure gauges find use in various applications. In the chemical industry, they are used to monitor the pressure of aggressive fluids. In food and beverage production, these gauges help ensure that processes maintain the correct pressure for safety and quality control. Additionally, in the pharmaceutical sector, Wika gauges are vital for compliance with stringent health regulations.

In the oil and gas industry, the robustness of Wika diaphragm gauges makes them ideal for monitoring pressure in harsh conditions, where traditional gauges might fail. They are also used in HVAC systems, water treatment facilities, and many other industrial applications.

Conclusion

High-quality Wika diaphragm pressure gauges represent an invaluable tool in diverse industries requiring reliable pressure measurements. Their robust construction, accuracy, and versatility make them the go-to choice for engineers and technicians seeking to enhance operational efficiency and ensure safety. By understanding the features and benefits of these gauges, industries can make informed choices that positively impact their processes and outcomes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025