Nov . 22, 2024 03:18 Back to list

high quality types of differential pressure gauges

High-Quality Types of Differential Pressure Gauges

Differential pressure gauges are crucial instruments used in various industries to measure the difference in pressure between two points in a system. They play a significant role in monitoring fluid flow, detecting blockages, and ensuring optimal operation of equipment. The quality of these gauges greatly affects their accuracy, reliability, and longevity. In this article, we will explore the high-quality types of differential pressure gauges that are commonly used in various applications.

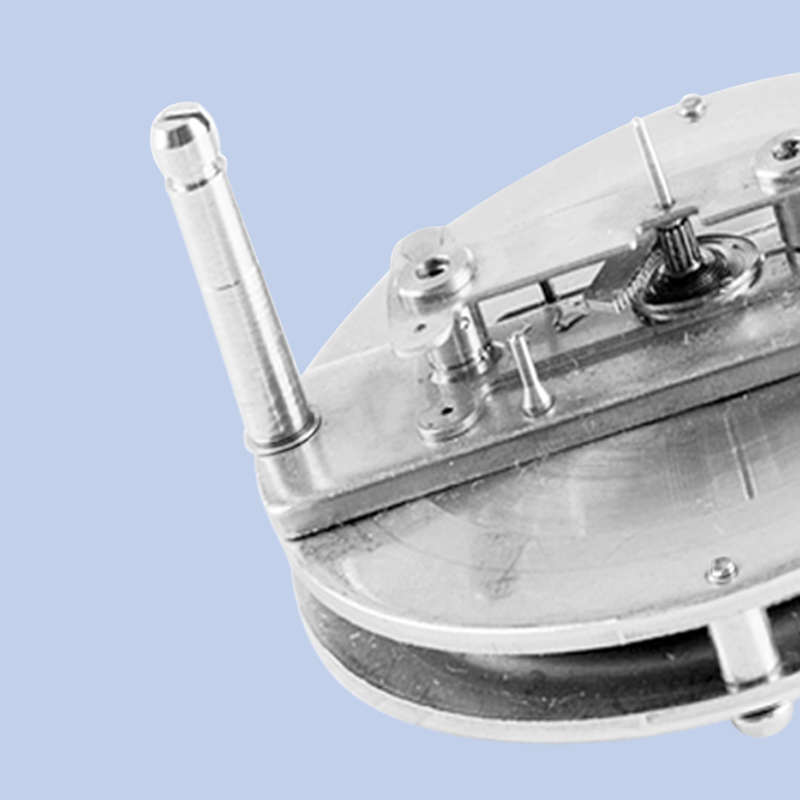

1. Diaphragm Differential Pressure Gauges

Diaphragm-based differential pressure gauges are among the most widely used types. They operate on the principle of a flexible diaphragm that deflects in response to pressure differentials. This technology provides high sensitivity and accuracy, making it suitable for measuring low-pressure differences. Diaphragm gauges are often used in applications involving gases and liquids that contain particulates, as the diaphragm can protect the internal mechanism from damage.

These gauges are available in various materials, including stainless steel and special alloys, which can withstand corrosive environments. Their robust design ensures durability and a long service life, making them a preferred choice for industries such as chemical processing and oil and gas.

2. Capacitive Differential Pressure Gauges

Capacitive differential pressure gauges utilize capacitive sensing technology to measure pressure differences. These gauges are known for their high precision and stability, offering excellent performance in a wide range of applications. The sensing element consists of two conductive plates separated by a dielectric material, with the distance between them changing as the pressure differential varies.

Capacitive gauges are particularly advantageous in cleanroom environments or where contamination must be minimized, as they have fewer moving parts compared to mechanical gauges. They are often used in pharmaceutical and semiconductor manufacturing, where precise pressure measurements are critical.

3. Piezoelectric Differential Pressure Gauges

Piezoelectric differential pressure gauges use piezoelectric materials that generate an electrical charge in response to applied pressure. This technology provides rapid response times and is capable of measuring dynamic pressure changes effectively, making it ideal for applications such as flow measurement and vibration analysis.

high quality types of differential pressure gauges

These gauges are often found in high-temperature or high-vibration environments, where traditional measurement methods may fail. The robustness and accuracy of piezoelectric gauges allow them to serve industries such as aerospace and automotive, where dependable performance is essential.

4. Electronic Differential Pressure Gauges

Electronic differential pressure gauges leverage advanced technology to provide high accuracy and easy data logging capabilities. They typically incorporate microprocessors that can process and display the pressure readings digitally. Some models offer connectivity features, allowing for real-time monitoring and integration into automated systems.

These gauges are highly versatile, suitable for applications ranging from HVAC systems to industrial processes. Their digital nature ensures low maintenance and high reliability, particularly in complex systems where precision measurement is critical.

5. Bourdon Tube Differential Pressure Gauges

Bourdon tube-based differential pressure gauges operate using a simple mechanical principle. The gauge consists of a coiled tube that responds to pressure changes by unwinding slightly, which moves a pointer across a dial, indicating the pressure difference. While mechanical in design, Bourdon tube gauges can be calibrated for high accuracy and are robust enough to handle harsh conditions.

These gauges are widely used in various industries, including water treatment and manufacturing, due to their reliability and straightforward design. They are often favored in applications where electronic gauges may be impractical or where power supply is not readily available.

Conclusion

Choosing the right type of differential pressure gauge is essential for achieving accurate measurements and maintaining system integrity. Whether opting for diaphragm, capacitive, piezoelectric, electronic, or Bourdon tube gauges, it's important to consider factors such as the application, environmental conditions, and required accuracy. High-quality differential pressure gauges not only enhance operational efficiency but also contribute significantly to the safety and reliability of industrial processes. As technology continues to evolve, the capabilities and features of these gauges are expected to improve further, paving the way for more precise and efficient monitoring in various industries.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025