Dec . 03, 2024 16:49 Back to list

Durable Sealed Diaphragm Pressure Gauge for Accurate Measurement and Performance

The Importance of High-Quality Sealed Diaphragm Pressure Gauges

In various industrial applications, maintaining precise measurements of pressure is crucial for ensuring operational safety, efficiency, and reliability. Among the plethora of instruments available for measuring pressure, high-quality sealed diaphragm pressure gauges stand out for their accuracy, durability, and versatility. This article delves into the intrinsic qualities of these gauges, their applications, and the factors to consider when selecting one for specific needs.

Understanding Diaphragm Pressure Gauges

A diaphragm pressure gauge operates using a flexible diaphragm that deflects when exposed to pressure. This deflection translates into a movement that drives a needle across a calibrated dial, indicating the pressure level. Sealed diaphragm pressure gauges feature a hermetically sealed design, which protects the internal components from external contaminants such as moisture, dust, and corrosive chemicals. This seal is vital for maintaining the integrity and longevity of the instrument.

Advantages of High-Quality Sealed Diaphragm Pressure Gauges

1. Accuracy and Precision High-quality gauges are engineered to provide accurate readings, which is essential in applications where even minor pressure fluctuations can result in significant consequences. These gauges are often calibrated to specific standards, ensuring reliable performance over time.

2. Durability and Longevity Sealed diaphragm pressure gauges are constructed from robust materials that can withstand harsh environments. The seal prevents ingress of harmful substances, reducing wear and tear and extending the life of the instrument. This durability makes them particularly suitable for demanding industrial settings.

3. Versatility These gauges can be utilized in a wide range of applications, from monitoring gas and liquid systems to assessing pressure in hydraulic systems. Their ability to function effectively in various media, including corrosive or viscous substances, makes them a versatile choice for many industries.

4. Low Maintenance The hermetically sealed design minimizes maintenance requirements, significantly reducing downtime and associated costs. Users can rely on these gauges for consistent performance without the frequent need for recalibration or repairs.

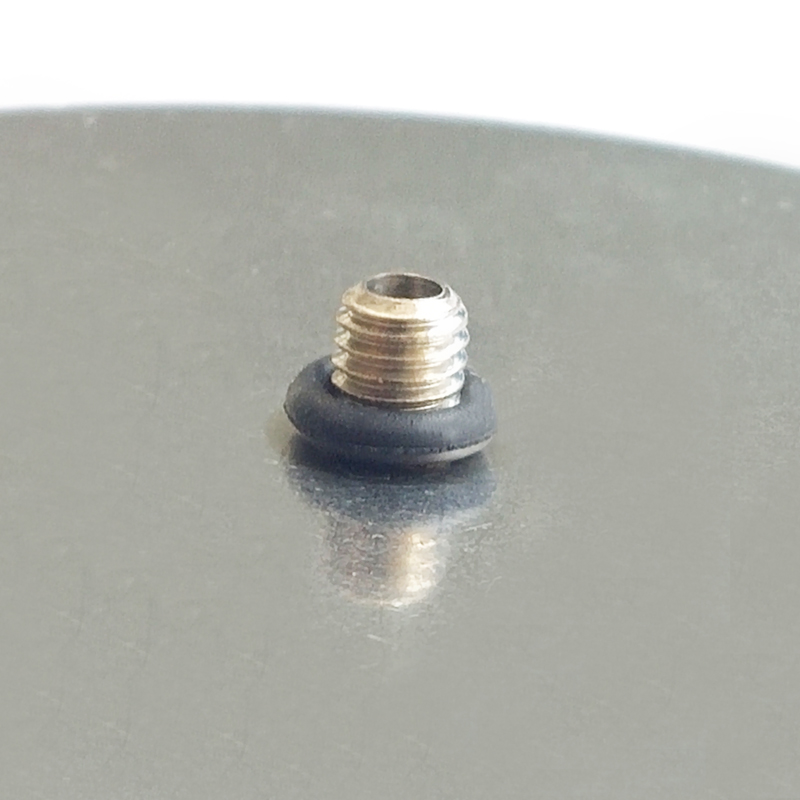

high quality sealed diaphragm pressure gauge

Applications of Sealed Diaphragm Pressure Gauges

Sealed diaphragm pressure gauges are widely used in numerous sectors, including

- Chemical Processing In environments where chemicals can cause damage, sealed gauges help in accurate pressure monitoring while protecting sensitive components. - Oil and Gas Industry operations require precise pressure readings for safety and efficiency; these gauges are invaluable in ensuring operational integrity. - Food and Beverage Ensuring sanitary conditions is key in food processing, and sealed gauges help monitor pressure in systems where contamination could lead to safety issues. - Pharmaceuticals Like food, medication production requires stringent adherence to safety standards, making high-quality pressure measurement crucial.

Selecting the Right Gauge

When choosing a sealed diaphragm pressure gauge, several factors should be considered

- Pressure Range It is vital to select a gauge that matches the pressure range of your application to ensure accuracy and reliability. - Material Compatibility The materials of the gauge must be compatible with the medium being measured. For corrosive environments, gauges made of stainless steel or special alloys should be considered. - Calibration Standards Opt for gauges that comply with industry calibration standards to ensure reliability in your measurements.

Conclusion

High-quality sealed diaphragm pressure gauges are essential tools for numerous industries. Their accuracy, durability, versatility, and low maintenance requirements make them invaluable for safe and efficient operations. By understanding their advantages and the factors to consider when selecting one, businesses can ensure they maintain optimal performance in their pressure monitoring needs. As industries continue to evolve, the role of accurate pressure measurement will only become more critical, reaffirming the importance of investing in quality instrumentation.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025