Nov . 12, 2024 10:08 Back to list

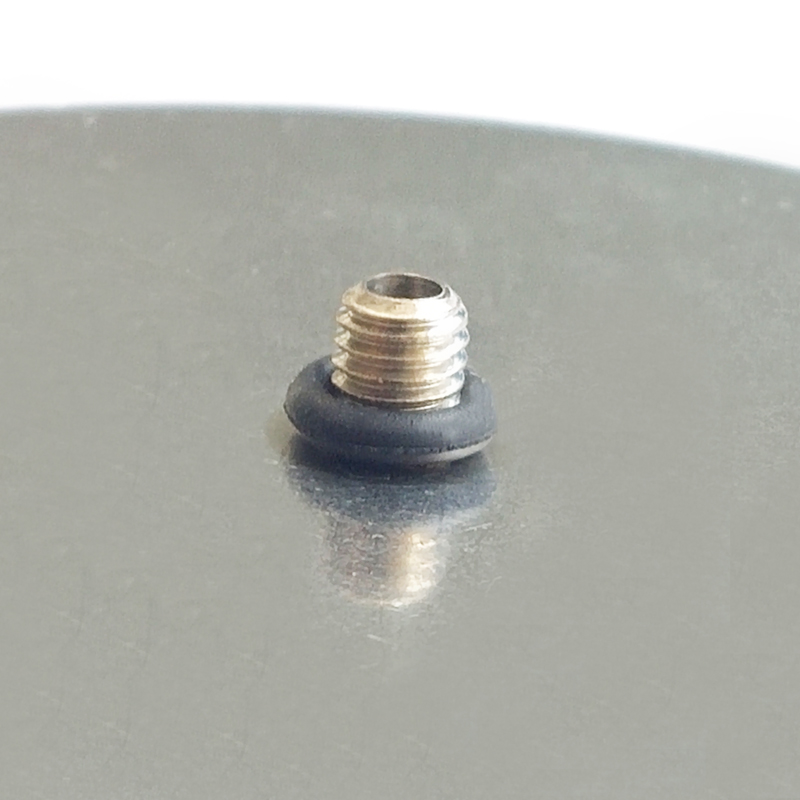

high quality differential pressure gauge with tattletale

Understanding High-Quality Differential Pressure Gauges with Tattletale Functionality

In various industrial applications, monitoring pressure is crucial for maintaining optimal processes and ensuring safety. Differential pressure gauges are essential instruments that measure the difference in pressure between two points. Among the myriad of options available, high-quality differential pressure gauges equipped with a tattletale feature stand out for their functionality and reliability. This article explores the importance, benefits, and applications of these specialized gauges.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the pressure difference between two chambers, vessels, or points in a system. This measurement is essential in various fields, including HVAC systems, water treatment facilities, and chemical processing plants. By monitoring pressure differentials, operators can assess system performance, detect blockages, and ensure proper fluid flow.

The Importance of Quality

When it comes to differential pressure gauges, the quality of the instrument plays a pivotal role in its performance. High-quality gauges provide accurate readings, ensuring that operators make informed decisions based on precise data. Additionally, the durability of the materials used in manufacturing these gauges can withstand the harsh conditions often present in industrial environments, such as temperature fluctuations, corrosion, and mechanical stress.

The Tattletale Feature Explained

The term tattletale in the context of differential pressure gauges refers to a built-in feature that records the highest and lowest pressure differential values experienced during a specified period. This functionality is particularly useful for monitoring system conditions over time, especially when operators are not consistently present to observe fluctuations.

A differential pressure gauge with a tattletale feature allows for

1. Historical Data Analysis By keeping track of maximum and minimum pressure readings, operators can analyze trends over time, identifying potential issues before they escalate into serious problems.

high quality differential pressure gauge with tattletale

2. Improved Maintenance Scheduling Regular data captured by the tattletale feature aids in preventive maintenance. Operators can schedule maintenance during less busy times to avoid any disruption in process flow.

3. Enhanced Troubleshooting In the event of a system failure, having access to past pressure readings can assist engineers in diagnosing the issue, thereby reducing downtime and enhancing system reliability.

Applications Across Industries

High-quality differential pressure gauges with tattletale capabilities can find applications across diverse industries

1. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges are used to monitor air flows and filter conditions. Ensuring that the differential pressure remains within specified limits optimizes energy consumption and enhances comfort.

2. Water Treatment In water treatment facilities, maintaining proper pressure differentials between filters is essential for efficient operation. Differential pressure gauges help ensure that filters are functioning correctly, allowing for timely cleaning or replacement.

3. Chemical Processing In chemical manufacturing, pressure differentials can indicate potential leaks or blockages in lines. Utilizing high-quality gauges with a tattletale feature enhances safety by providing real-time data and historical trends for ongoing process evaluation.

Conclusion

High-quality differential pressure gauges with tattletale functionality are vital tools in modern industrial applications. Their ability to provide accurate measurements, record historical data, and improve maintenance practices significantly enhances operational efficiency and safety in various fields. As industries continue to evolve, the importance of precision monitoring instruments like differential pressure gauges will undoubtedly grow, ensuring that systems operate smoothly and remain safe over their lifespan. Embracing these advanced technologies not only leads to better management practices but also fosters a proactive approach to process optimization and risk management.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025