Nov . 03, 2024 17:15 Back to list

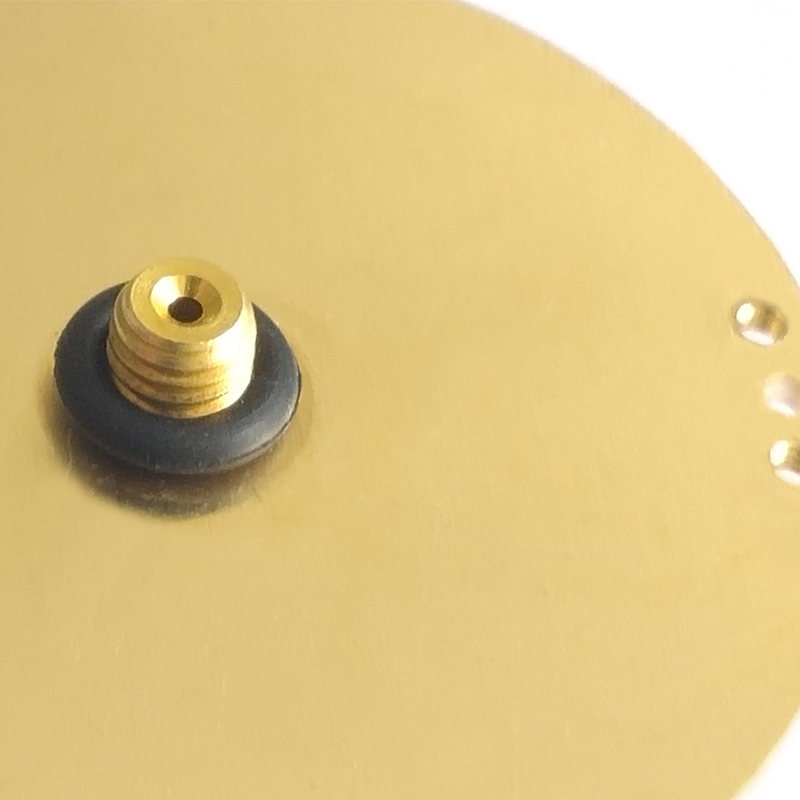

high quality differential pressure gauge diaphragm

High-Quality Differential Pressure Gauge Diaphragm An Overview

In various industrial applications, precise measurement of pressure differentials is crucial for ensuring operational efficiency and safety. A key component in these measurements is the differential pressure gauge diaphragm, which plays a pivotal role in transforming pressure changes into readable outputs. This article explores the significance, functions, and advantages of high-quality differential pressure gauge diaphragms.

A differential pressure gauge is designed to measure the difference in pressure between two points, often in processes involving fluids or gases. The diaphragm acts as a flexible barrier that separates two pressure chambers. When a pressure change occurs, the diaphragm flexes, creating a mechanical movement that is translated into a measurement by the gauge's mechanism. The accuracy of this reading is heavily dependent on the quality of the diaphragm used.

High-quality diaphragms are typically made from materials that offer superior resistance to corrosion and wear, such as stainless steel, Monel, or other specialized alloys

. These materials not only ensure durability but also help maintain the integrity of the measurement under varying environmental conditions, such as temperature fluctuations and exposure to harsh chemicals. Additionally, a well-designed diaphragm can handle high pressures without compromising its shape or functionality, thus providing reliable data over an extended period.high quality differential pressure gauge diaphragm

One of the significant advantages of using a high-quality differential pressure gauge diaphragm is its ability to minimize hysteresis and improve sensitivity. Hysteresis refers to the lag between pressure application and measurement response, which can lead to inaccuracies. A high-quality diaphragm minimizes this effect, allowing for more immediate and precise readings. Furthermore, enhanced sensitivity means that even small changes in pressure can be detected, which is essential in applications like filtration monitoring, level measurement, and HVAC systems.

Moreover, high-quality diaphragms can be tailored to suit specific applications. They can be designed to accommodate varying ranges of pressure, temperature, and specific chemical compatibilities, providing versatility across different industrial settings. This customization ensures that the diaphragm will perform optimally, regardless of the working conditions, further reinforcing the importance of selecting high-quality components.

In conclusion, the diaphragm in a differential pressure gauge is fundamental to achieving accurate and reliable pressure measurements. Investing in high-quality diaphragms not only enhances measurement precision but also extends the lifespan of the equipment, reduces maintenance costs, and improves overall operational efficiency. As industries continue to evolve, the importance of quality components in pressure measurement systems will remain a focal point for engineers and operators alike. Ultimately, the effectiveness of a differential pressure gauge hinges on the excellence of its diaphragm, making it a crucial aspect of system performance in any application.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025