Oct . 21, 2024 15:59 Back to list

high quality capillary diaphragm seal pressure gauge

Understanding High-Quality Capillary Diaphragm Seal Pressure Gauges

Pressure measurement is a critical aspect of various industrial processes, ensuring safety and efficiency. Among the myriad of options available, high-quality capillary diaphragm seal pressure gauges have emerged as a superior choice, particularly in challenging environments. These instruments combine reliability, precision, and durability, making them indispensable in many applications.

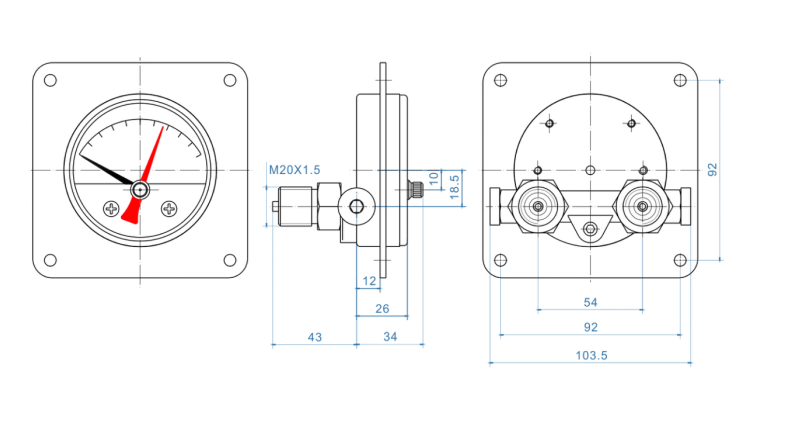

At the core of a capillary diaphragm seal pressure gauge is its unique design, which incorporates a diaphragm that isolates the pressure-sensing element from the process media. This feature is particularly beneficial when measuring the pressure of corrosive or high-viscosity fluids. The diaphragm, typically made from materials like stainless steel or special alloys, is designed to withstand extreme conditions, ensuring the gauge remains functional and accurate.

One of the standout attributes of high-quality capillary diaphragm seal pressure gauges is their ability to maintain performance over a wide temperature range. This quality is essential in industries such as oil and gas, chemical processing, and food and beverage, where temperature fluctuations can significantly affect the accuracy of pressure readings. The capillary tube, which connects the diaphragm to the gauge, can be extended and shaped, allowing for remote monitoring and the ability to position the gauge in a more accessible location.

high quality capillary diaphragm seal pressure gauge

Moreover, these gauges minimize the effects of pulsation and vibration, which are common in many industrial processes. The diaphragm absorbs shocks and fluctuations, leading to more stable and reliable readings. This stability is crucial for ensuring that processes remain within safe operational limits, thereby preventing accidents and equipment failure.

When selecting a high-quality capillary diaphragm seal pressure gauge, various factors come into play, including the gauge’s material, pressure range, and connection type. It’s essential to consider the specific application and the properties of the process media. For example, if the fluid is particularly corrosive, selecting a diaphragm made from a compatible material is vital for longevity and functionality.

In conclusion, high-quality capillary diaphragm seal pressure gauges offer a robust and reliable solution for pressure measurement in demanding environments. Their design not only protects sensitive components from harsh media but also ensures accurate readings despite challenging conditions. As industries continue to evolve, the demand for precise and durable pressure measurement solutions like these gauges will undoubtedly grow, solidifying their role in promoting safety and efficiency.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025