Oct . 22, 2024 09:47 Back to list

High-Pressure Differential Pressure Gauge for Accurate Measurements and Monitoring Applications

Understanding High-Pressure Differential Pressure Gauges

Differential pressure gauges are essential instruments in various industrial applications, providing critical measurements that ensure operational efficiency and safety. Among these, high-pressure differential pressure gauges are particularly important in processes that involve significant pressure variations, such as in oil and gas, chemical manufacturing, and power generation. This article delves into the fundamentals of high-pressure differential pressure gauges, their applications, construction, and the principles governing their operation.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points within a system. This is crucial for evaluating how much pressure is lost as fluid travels through pipes, filters, or other equipment. The gauge can provide insights into the performance of processes and help identify issues such as clogs or blockages, which could lead to inefficiencies or equipment failure.

High-pressure differential pressure gauges are designed to withstand and accurately measure substantially high pressure differentials, often exceeding normal operational limits of standard gauges. This capability is vital in applications where pressure differentials can lead to dangerous conditions if not properly monitored.

Construction of High-Pressure Differential Pressure Gauges

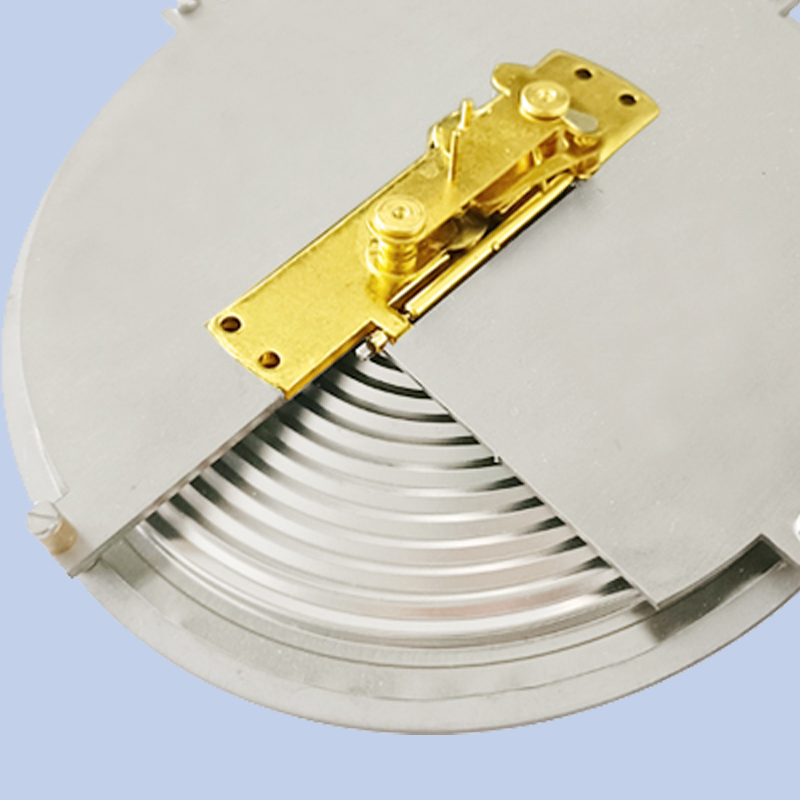

High-pressure differential pressure gauges consist of several critical components

1. Sensing Elements These are typically made from durable materials that can withstand high pressures. Common materials include stainless steel and other alloys that resist corrosion and deformation.

2. Diaphragm The diaphragm membrane flexes in response to pressure differences, transferring the pressure variation to a mechanical or electronic indicator.

3. Sealing System The integrity of the sealing system is crucial in high-pressure applications. Proper sealing ensures that the gauge remains accurate and that no fluid leaks influence the pressure readings.

4. Calibration Mechanism Accurate readings depend on proper calibration. High-pressure differential pressure gauges often include built-in calibration features to maintain accuracy over time.

5. Display Depending on the model, gauges can feature analog dials or digital displays. Advanced models may also include output options for integration with computerized monitoring systems.

high pressure differential pressure gauge

Operating Principles

The fundamental principle behind high-pressure differential pressure gauges is quite straightforward. As pressure is applied to either side of the diaphragm, it flexes, distorting its shape. The amount of deflection is proportional to the difference in pressure.

In a typical gauge setup, one side is connected to a high-pressure source, while the other is exposed to a lower-pressure environment (or atmospheric pressure). The gauge reads the differential and provides a direct measurement that operators can interpret in real-time.

Applications of High-Pressure Differential Pressure Gauges

High-pressure differential pressure gauges find applications in several areas, including

1. Oil and Gas Industry In drilling operations and pipeline monitoring, these gauges are critical for ensuring safety as they help monitor pressure differences that can indicate leaks or other hazardous conditions.

2. Chemical Processing Many chemical reactions depend on the maintenance of specific pressure conditions. Differential pressure gauges help in monitoring the pressures associated with reactors and distillation columns to optimize production and ensure safety.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor the pressure of air moving through filters and ducts, allowing operators to detect blockages that can reduce efficiency.

4. Water Treatment Facilities Maintaining the correct pressure differential across filters is vital in water treatment processes, ensuring contaminants are effectively removed.

5. Power Generation In power plants, differential pressure gauges monitor boiler operations and cooling system pressures, which are crucial for safe and efficient energy production.

Conclusion

High-pressure differential pressure gauges are indispensable tools that provide vital measurements across various industries. Their ability to accurately monitor significant pressure differentials ensures operational efficiency, safety, and process optimization. Understanding how these instruments function and their applications can help industries minimize risks and enhance productivity, proving that effective pressure management is essential for any high-stakes environment. As technology advances, these gauges will continue to evolve, offering even more accurate and reliable measurements to support the ever-increasing demands of modern industry.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025