Aug . 20, 2024 16:28 Back to list

High Accuracy Stainless Steel Differential Pressure Gauge for Industrial Applications

Understanding Stainless Steel Differential Pressure Gauges

Differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points. These devices are particularly critical in processes where maintaining specific pressure levels is crucial for efficiency and safety. Among the various materials used for manufacturing pressure gauges, stainless steel is widely preferred due to its durability, corrosion resistance, and reliability. This article will delve into the features, applications, and advantages of stainless steel differential pressure gauges.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points within a system. This could include various applications, such as monitoring the performance of filters, pumps, or HVAC systems. The gauge typically consists of a sensing element, which could be a diaphragm, capsule, or Bourdon tube, and it translates the pressure difference into a readable format, often indicated by a needle on a dial or a digital display.

The Advantages of Stainless Steel in Pressure Gauges

1. Corrosion Resistance One of the significant advantages of stainless steel is its excellent resistance to corrosion. In industries such as chemical processing, waste management, and pharmaceuticals, the presence of corrosive substances is common. Using stainless steel for differential pressure gauges ensures longevity and reduces the need for frequent replacements.

2. Durability Stainless steel is incredibly durable and can withstand harsh environments. This makes it suitable for applications involving extreme temperatures and pressures. Gauges made from stainless steel are less likely to suffer damage from mechanical shock or vibration, adding to their reliability.

3. Hygienic Properties In industries like food and beverage and pharmaceuticals, hygiene is paramount. Stainless steel is non-porous and can be easily cleaned, preventing the buildup of contaminants. This makes stainless steel differential pressure gauges an ideal choice for monitoring processes where cleanliness is crucial.

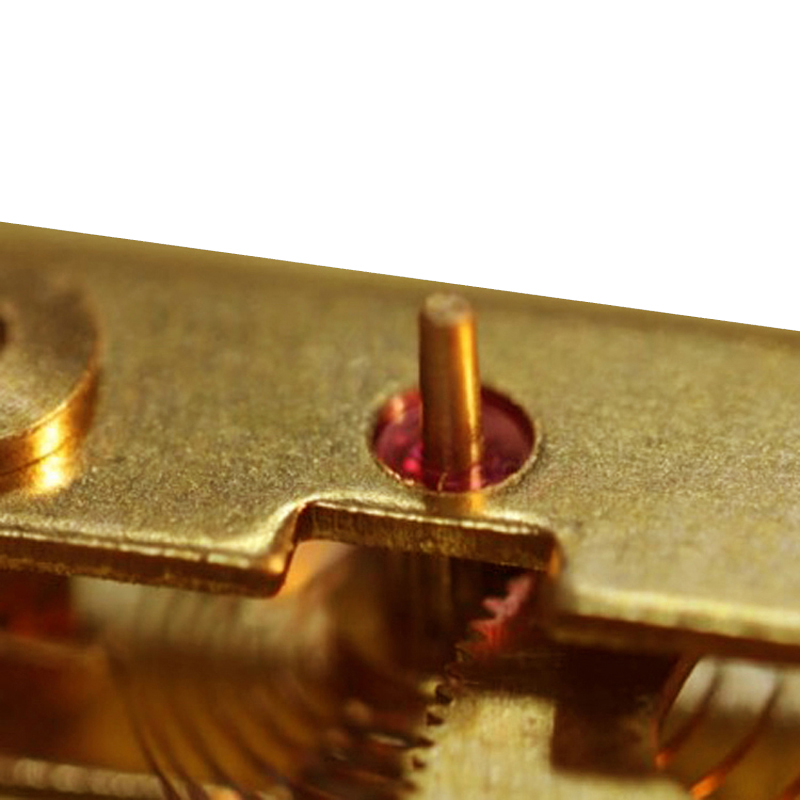

stainless steel differential pressure gauge product

4. Accuracy and Precision Differential pressure gauges made from stainless steel are designed to provide precise measurements. Their robust construction helps avoid readings affected by environmental conditions, thus ensuring that operators can rely on the data the gauges provide.

Applications of Stainless Steel Differential Pressure Gauges

Stainless steel differential pressure gauges find applications in a diverse range of sectors

- HVAC Systems Monitoring air filters and pressure drops in duct systems to optimize energy efficiency and ensure indoor air quality. - Water and Wastewater Treatment Measuring pressure differences across filters and pumps to maintain effective operation and protect equipment.

- Chemical Processing Used to monitor pressure differences in reactors, tanks, and pipelines, ensuring proper process control and safety.

- Oil and Gas In exploration and production, these gauges are critical in maintaining the efficiency and safety of equipment.

Conclusion

In summary, stainless steel differential pressure gauges are indispensable tools in various industries due to their excellent properties, including corrosion resistance, durability, and accuracy. Their ability to perform reliably in harsh environments ensures effective monitoring of processes that rely on precise pressure measurements. As industries continue to innovate and evolve, stainless steel differential pressure gauges will undoubtedly remain a cornerstone of safe and efficient operations. Whether in HVAC systems, chemical processing, or any other application, understanding and utilizing these gauges effectively can lead to significant improvements in productivity and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025