Nov . 06, 2024 19:45 Back to list

Manufacturers of Flush Diaphragm Pressure Gauges and Their Applications in Various Industries

Understanding Flush Diaphragm Pressure Gauges A Comprehensive Overview of Manufacturers

In the realm of industrial measurement instrumentation, the flush diaphragm pressure gauge stands out as a crucial device in various applications requiring precision and reliability. These gauges are designed to measure pressure in corrosive, viscous, or particulate-laden fluids that can readily clog traditional pressure measurement systems. In this article, we will delve into what makes flush diaphragm pressure gauges essential, and explore some leading manufacturers in the industry.

What is a Flush Diaphragm Pressure Gauge?

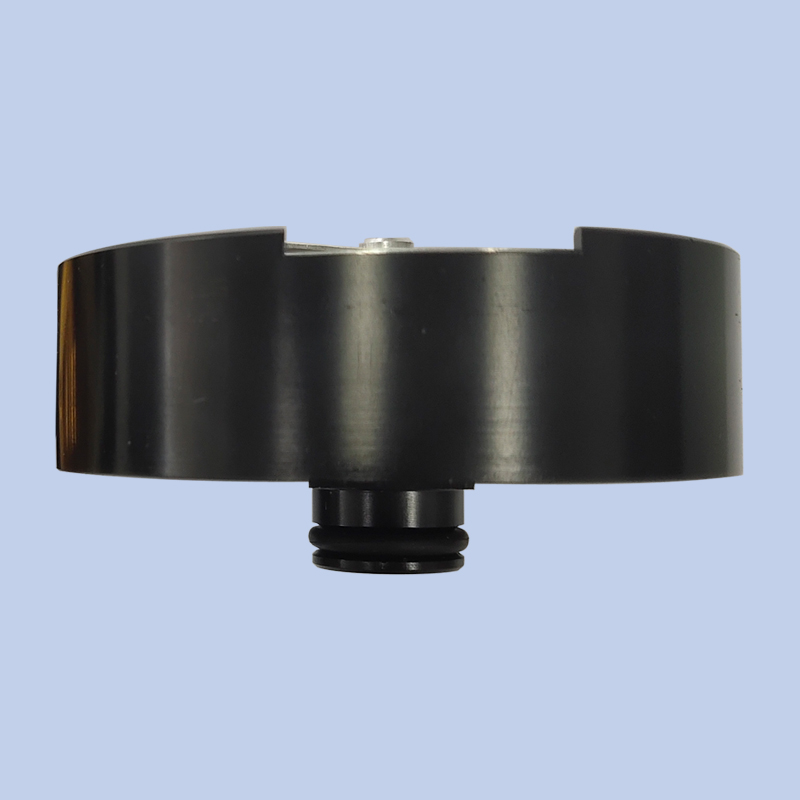

Flush diaphragm pressure gauges are devices equipped with a flexible diaphragm that separates the measuring fluid from the pressure sensing element. This design enables them to be used in applications where the fluid's properties might otherwise damage standard pressure sensors. Additionally, the flushed design minimizes dead space, allowing for more accurate readings by preventing buildup and contamination.

These gauges are widely used across various industries, including oil and gas, pharmaceuticals, food and beverage processing, and chemical manufacturing, where they monitor pressure in challenging environments without compromising accuracy or functionality.

Key Components of Flush Diaphragm Pressure Gauges

1. Diaphragm Material The diaphragm is typically made from materials that resist corrosion, such as stainless steel or specialized alloys, ensuring durability even in harsh conditions. 2. Sealing and Fitting Designs A well-designed sealing mechanism and fittings ensure that the gauge maintains integrity under pressure and prevents leaks. 3. Connection Types Different connection types (such as sanitary and threaded) allow versatility for integration into varying piping systems.

4. Calibration and Certification Reliable manufacturers provide gauges that are pre-calibrated and certified for accuracy, which is crucial for compliance with industry standards.

Leading Manufacturers in the Industry

Several manufacturers have established a reputation for producing high-quality flush diaphragm pressure gauges. Here are a few notable companies

flush diaphragm pressure gauge manufacturers

1. Omega Engineering Known for a variety of measurement devices, Omega offers a robust selection of flush diaphragm pressure gauges suitable for multiple industries. Their products are renowned for accuracy and are widely used in critical applications.

2. WIKA A leading name in pressure measurement, WIKA provides innovative flush diaphragm gauges that feature advanced technology and robust construction. Their gauges accommodate both liquid and gas applications, ensuring excellent performance in diverse conditions.

3. Ashcroft With a reputation for reliability, Ashcroft manufactures pressure gauges that effectively handle demanding environments. Their flush diaphragm gauges are designed to minimize maintenance, thus enhancing operational efficiency.

4. Budenberg Focusing on high-performance pressure gauges, Budenberg offers flush diaphragm designs that cater to specific industry demands. Their products are engineered for high accuracy and exhibit exceptional durability.

5. Keller AG Keller's flush diaphragm pressure sensors and gauges are designed for precision in hostile environments. Their innovative technology ensures long-term stability and low maintenance costs.

Applications in Industry

Flush diaphragm pressure gauges are particularly beneficial in processes involving high levels of solids, slurries, or caustic fluids. For example, in the food industry, maintaining hygiene while measuring pressure in liquids is paramount, making these gauges invaluable. In pharmaceuticals, they help monitor critical processes while preventing contamination.

Conclusion

Flush diaphragm pressure gauges represent a significant advancement in industrial measurement technologies. The ability to accurately measure pressure in challenging environments opens new opportunities for improved efficiency and safety across various industries. By partnering with reputable manufacturers like Omega, WIKA, Ashcroft, Budenberg, and Keller AG, businesses can ensure they have reliable instruments that meet their specific needs, paving the way for success in their operational endeavors. As industries continue to evolve, the demand for such specialized monitoring equipment is likely to grow, further cementing the importance of flush diaphragm pressure gauges in modern industrial practices.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025