Nov . 30, 2024 03:53 Back to list

Fire Sprinkler Pressure Gauge Manufacturing Process and Quality Standards Overview

Understanding Fire Sprinkler Pressure Gauge Factories

In the realm of fire safety, fire sprinkler systems play a pivotal role in protecting properties and saving lives. To ensure these systems function effectively, maintaining appropriate pressure levels is crucial. This is where fire sprinkler pressure gauges come into play. These instruments are essential for monitoring the water pressure in sprinkler systems, ensuring that they are ready to activate in the event of a fire. This article explores the role of factories producing fire sprinkler pressure gauges, the technology behind these devices, and their importance in the firefighting industry.

The Role of Fire Sprinkler Pressure Gauge Factories

Fire sprinkler pressure gauge factories specialize in manufacturing devices designed to monitor the pressure of water in sprinkler systems. These facilities employ advanced manufacturing techniques to produce high-quality gauges that comply with stringent safety standards. The production process typically involves precise engineering and the use of durable materials to ensure long-lasting performance under various conditions.

Factories producing these gauges must maintain high levels of quality control. This is vital, as any malfunction in a pressure gauge could result in catastrophic failures of the sprinkler system during a fire event. Thus, manufacturers often adhere to international standards such as ISO (International Organization for Standardization) to ensure their products are reliable and effective.

Types of Fire Sprinkler Pressure Gauges

There are various types of fire sprinkler pressure gauges available on the market, each designed for specific applications

. The most common types include1. Analog Gauges These traditional gauges use a dial and a needle to indicate the pressure level. They are easy to read and require no batteries, making them a reliable choice for many applications.

2. Digital Gauges Digital pressure gauges offer enhanced accuracy and the ability to display multiple readings at once. They may include features such as data logging, alarms, and wireless connectivity, allowing for real-time monitoring of pressure levels.

3. Differential Gauges These gauges measure the difference in pressure between two points, which can be particularly useful in identifying blockages or leaks in a sprinkler system.

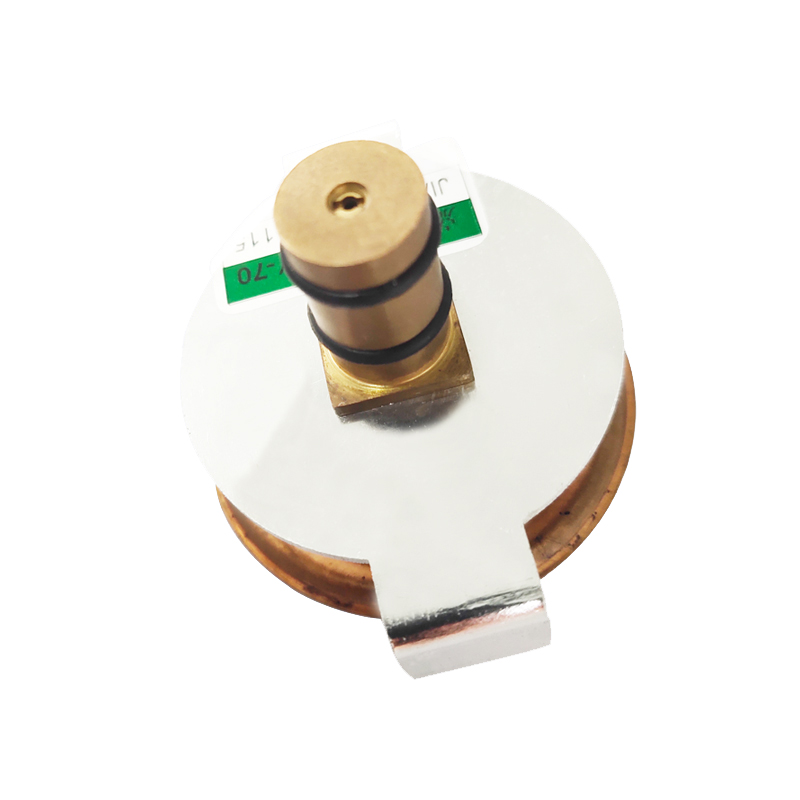

fire sprinkler pressure gauge factories

4. Submersible Gauges Designed for use in sump pits and cisterns, submersible gauges are built to withstand harsh conditions and provide accurate readings even when submerged in water.

Technology Behind Pressure Gauges

Modern fire sprinkler pressure gauges utilize advanced technology to enhance their functionality. Many digital gauges are equipped with sensors that can detect minute changes in pressure, ensuring that any drop in water supply is immediately identified. Furthermore, the integration of Internet of Things (IoT) technology allows these gauges to communicate with central monitoring systems, providing real-time updates and alerts to facility managers.

Manufacturers also focus on improving the durability of their products. High-quality gauges are often made with corrosion-resistant materials, ensuring they perform reliably in varying environmental conditions. This feature is particularly important for systems installed in areas exposed to harsh weather, where equipment can be subjected to moisture, heat, and cold.

Importance in Fire Safety

The significance of fire sprinkler pressure gauges cannot be overstated. These devices are integral to the overall functionality of fire sprinkler systems, which are designed to activate automatically when a fire occurs. Ensuring that the pressure within these systems is constantly monitored helps prevent situations where sprinklers fail to deliver water, potentially resulting in extensive property damage or loss of life.

Regular maintenance of pressure gauges is also critical. Facility managers must ensure that these devices are regularly calibrated and tested for accuracy. Some manufacturers offer maintenance programs that include routine checks and servicing to ensure that all equipment remains in optimal working condition.

Conclusion

Fire sprinkler pressure gauge factories play a crucial role in the fire protection industry by providing the necessary tools to ensure sprinkler systems operate effectively. By adhering to strict manufacturing standards and utilizing advanced technology, these manufacturers contribute significantly to fire safety. As buildings and infrastructure become more complex, the demand for reliable and accurate pressure monitoring devices will continue to grow, highlighting the importance of innovation and quality in the production of fire sprinkler pressure gauges. The commitment to excellence in manufacturing not only enhances the performance of sprinkler systems but ultimately contributes to saving lives and protecting property in the event of a fire.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025