Dec . 31, 2024 11:31 Back to list

Reliable Diaphragm Seal Pressure Gauge for Accurate Measurement and Performance

Understanding Diaphragm Seal Pressure Gauges The Famous Wika Example

Pressure gauges are vital instruments used in various industries to measure the pressure of gases and liquids. Among the different types of pressure gauges available, the diaphragm seal pressure gauge has gained prominence for its reliability and versatility. One of the most recognized names in this field is Wika, a global leader in pressure and temperature measurement technology. This article delves into the significance, functionality, and advantages of diaphragm seal pressure gauges, particularly focusing on Wika products.

What is a Diaphragm Seal Pressure Gauge?

A diaphragm seal pressure gauge is designed for measuring pressure in applications where a standard gauge would not be effective. The core component of this device is the diaphragm – a flexible membrane that separates the measuring element from the medium being measured. When pressure is applied to the fluid, the diaphragm flexes, translating that movement into a readable pressure measurement.

Diaphragm seal gauges are particularly beneficial in scenarios involving harsh and corrosive environments, high viscosities, or high temperatures. By keeping the sensing element isolated from the process media, these gauges ensure accurate readings without the risk of contamination or damage.

The Wika Advantage

Wika is renowned for its innovation and quality in the field of pressure measurement. Their diaphragm seal pressure gauges stand out due to several unique features

1. Robust Design Wika products are engineered to withstand extreme conditions. Their diaphragm seals are made from materials like stainless steel, making them resistant to corrosion and suitable for a wide range of applications, including chemical processing and food production.

2. High Accuracy Wika diaphragm seal gauges are designed to provide precise measurements, which is crucial in industrial applications where accuracy can impact safety and efficiency. The excellent repeatability and minimal hysteresis of these gauges enhance their reliability.

3. Wide Range of Applications These gauges are versatile and can be used in various industries, including oil and gas, pharmaceuticals, water treatment, and food and beverage. Wika's extensive catalog caters to diverse process requirements, providing tailored solutions that meet specific needs.

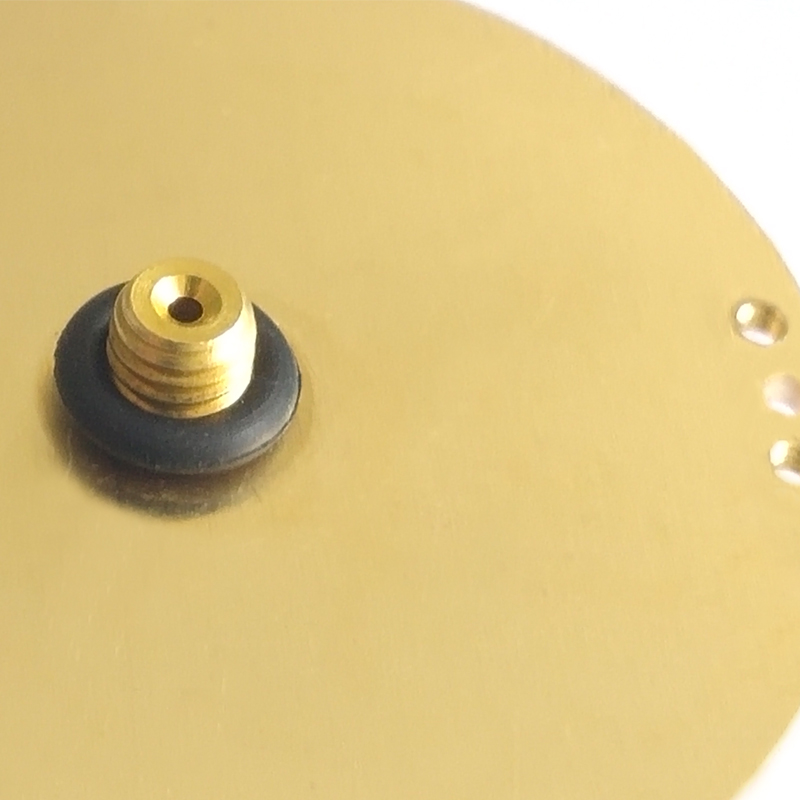

famous wika pressure gauge with diaphragm seal

4. Customization Options Wika offers a variety of diaphragm seal configurations, allowing users to customize their pressure gauges according to the characteristics of the media being measured. This adaptability enhances the effectiveness of the gauge in specialized applications.

5. User-Friendly Features Wika diaphragm seal pressure gauges are designed with the end-user in mind. Many models come with features such as easy-to-read dials, enhanced safety mechanisms, and straightforward installation procedures, making them accessible for operators.

Applications of Diaphragm Seal Pressure Gauges

Diaphragm seal pressure gauges are employed in numerous industrial applications where standard gauges might fail. Some common uses include

- Chemical Processing In environments with aggressive chemicals, the diaphragm seal protects the gauge from corrosive substances, ensuring a long service life and accurate readings. - Food and Beverage Industry Maintaining hygiene is critical in food processing. Diaphragm seals ensure that no contaminants enter the pressure measuring system, which is essential for meeting health and safety standards.

- Pharmaceutical Sector Precision is vital in pharmaceuticals. These gauges help ensure that pressures are maintained within the required parameters during production processes.

- Water and Wastewater Management Diaphragm seal gauges monitor pressures in pipes and tanks, aiding in proper system management and preventing failures.

Conclusion

Wika's diaphragm seal pressure gauges exemplify the cutting-edge technology and reliability required in today’s demanding industrial environments. By isolating the gauge mechanism from the process medium, these gauges offer unparalleled durability and accuracy. Whether in chemical plants, food and beverage facilities, or water treatment facilities, Wika's solutions ensure that industries can operate safely and efficiently. As the demand for precise and reliable pressure measurement continues to grow, diaphragm seal pressure gauges will remain pivotal for various applications, showcasing the enduring legacy of Wika in measurement technology.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025