Dec . 13, 2024 07:38 Back to list

High-Accuracy Digital Pressure Gauge for Precise Measurements in Various Applications

The Importance of Precision in Digital Pressure Gauges

In modern industrial applications, precision in measuring instruments is paramount. One such instrument that plays a crucial role is the digital pressure gauge. These gauges are vital for ensuring that machinery operates within the specified pressure limits, and they are widely used across various sectors, including manufacturing, automotive, aerospace, and even food processing. The famous precision digital pressure gauge stands out for its accuracy, reliability, and advanced technology, making it an essential tool for engineers and technicians alike.

What is a Digital Pressure Gauge?

A digital pressure gauge is an electronic device designed to measure the pressure of gases or liquids within a system. Unlike traditional analog gauges, which rely on mechanical dials and pointers, digital pressure gauges use electronic sensors to provide real-time measurements on a digital display. This advancement not only enhances the readability of the measurements but also improves response time and overall accuracy.

Key Features of Precision Digital Pressure Gauges

One of the most significant advantages of using precision digital pressure gauges is their high level of accuracy. These gauges are often equipped with advanced sensors that detect pressure changes with minimal tolerance for error. Many models offer accuracy levels within ±0.1% of the reading, making them suitable for applications where precise measurements are crucial.

Additionally, the display on digital gauges often features backlighting and large numerical readouts, which allows for easy reading even in low-light environments. Many models also come with various units of measurement, including psi, bar, and kPa, enabling users to select the most relevant unit for their application.

Another essential feature is the data logging capability. Some high-end digital pressure gauges can record pressure readings over time, allowing users to track performance and diagnose issues more effectively. This feature is particularly useful in environments where pressure variations can indicate problems, such as leaks in gas pipelines or fluctuating pressures in hydraulic systems.

Applications

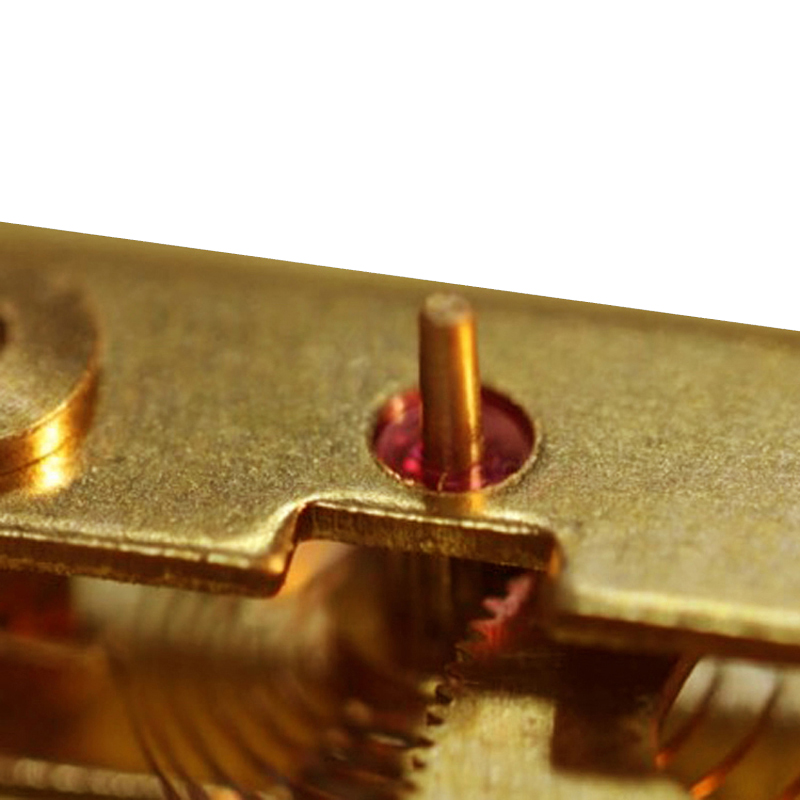

famous precision digital pressure gauge

Precision digital pressure gauges find applications in various fields. In the manufacturing sector, they are used to monitor the pressure of compressed air and other fluids within machinery, ensuring optimal functioning and preventing malfunctions. In the automotive industry, these gauges are critical for testing tire pressures, fuel systems, and more, ensuring safety and performance standards are maintained.

In the aerospace sector, precision digital pressure gauges are employed in both ground testing and in-flight monitoring of aircraft systems. Given the critical nature of flight safety, the need for accurate and reliable pressure measurements is non-negotiable. Similarly, in food processing, these gauges help regulate pressure in packaging processes, ensuring food safety and quality.

The Benefits of Using Precision Digital Pressure Gauges

The benefits of using famous precision digital pressure gauges are significant. Firstly, their high accuracy contributes to better operational efficiency. By ensuring that equipment operates within the correct pressure range, the risk of equipment failure decreases, leading to less downtime and, consequently, reduced operational costs.

Secondly, the ability to store and analyze data enhances decision-making processes. Engineers can identify trends and patterns over time, which aids in predictive maintenance strategies—addressing potential issues before they escalate into serious problems.

Moreover, many digital pressure gauges are designed to withstand harsh environmental conditions. Features such as waterproofing, rugged casings, and temperature resistance ensure these devices perform reliably in various settings, from factory floors to outdoor installations.

Conclusion

In conclusion, the famous precision digital pressure gauge is an indispensable tool in modern industrial applications. Its high level of accuracy, ease of use, and advanced features make it an invaluable resource for professionals across multiple industries. As technology continues to advance, these instruments will only become more sophisticated, further enhancing their ability to provide critical pressure measurements. Investing in quality digital pressure gauges is not just about compliance; it is a commitment to safety, efficiency, and long-term operational success.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025