Dec . 07, 2024 15:31 Back to list

famous piston type differential pressure gauge

The Piston Type Differential Pressure Gauge An Overview

In the realm of industrial instrumentation, accurate measurement of pressure is crucial for optimizing processes and ensuring safety. Among various types of pressure gauges, the piston type differential pressure gauge has emerged as a favored choice due to its precision, reliability, and ability to measure pressure differences in various operational environments.

What is a Piston Type Differential Pressure Gauge?

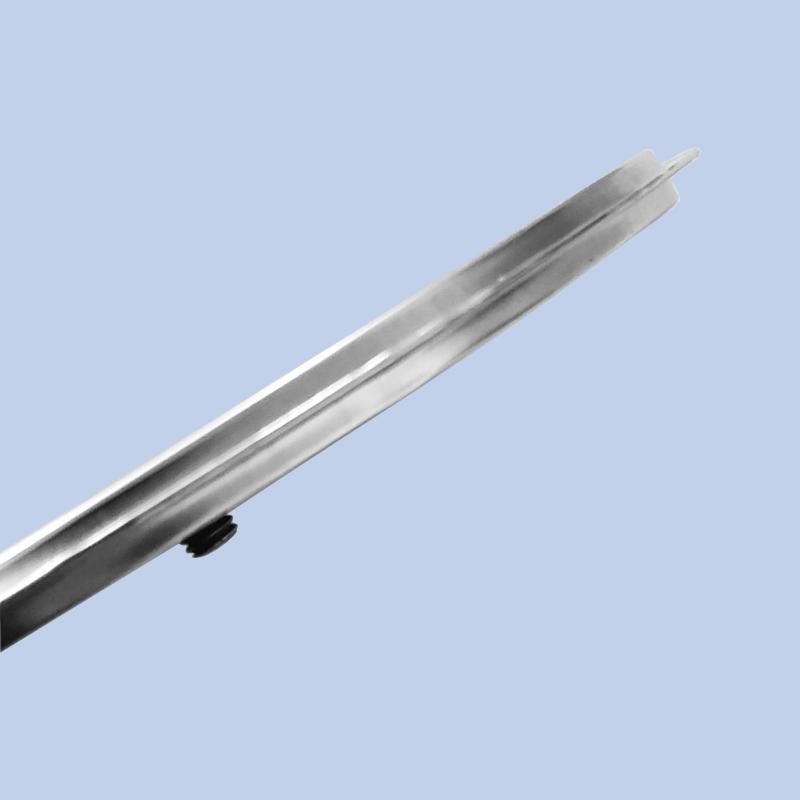

A piston type differential pressure gauge is designed to measure the difference in pressure between two points in a system. This is particularly useful in applications where monitoring the flow of liquids or gases is critical. The gauge consists of a piston that moves in response to pressure changes in two separate chambers, each connected to the pressure points being monitored. The displacement of the piston is translated into a readable measurement, typically displayed on a dial.

One of the inherent advantages of this type of gauge is its mechanical design, which provides high accuracy and sensitivity. The simplicity of the piston mechanism minimizes the likelihood of failure, making it a robust option for various industrial applications.

Advantages of Piston Type Differential Pressure Gauges

1. High Accuracy and Sensitivity The design of the piston type gauge allows for a small pressure differential to produce a significant movement of the piston, leading to precise readings even at low pressure differences.

2. Durability Piston gauges are typically constructed from durable materials that can withstand harsh operating conditions, including extreme temperatures and corrosive environments.

famous piston type differential pressure gauge

4. Versatility These gauges can be utilized in various fields, including oil and gas, water treatment, HVAC systems, and process industries. They can measure liquids, gases, and steam, which enhances their usability across different sectors.

5. Safety By providing accurate and immediate readings of pressure differentials, these gauges are instrumental in preventing overpressure situations, which can lead to system failures or accidents.

Applications of Piston Type Differential Pressure Gauges

Due to their versatility and reliability, piston type differential pressure gauges are widely used in numerous industrial applications

- Filtration Systems In filtration processes, these gauges monitor pressure drops across filters, ensuring that they operate efficiently without clogging. - Flow Measurement Differential pressure gauges can be employed to determine flow rates in pipelines by measuring the pressure difference across an orifice, venturi, or similar flow restriction. - Level Measurement These gauges are also used in tanks and vessels to measure liquid levels by comparing the hydrostatic pressure at various points. - Safety Systems In critical safety systems, such as those used in nuclear plants or chemical processing facilities, they monitor the differential pressure to ensure safe operational parameters are maintained.

Conclusion

In conclusion, the piston type differential pressure gauge stands out as a vital tool in industrial applications where precise pressure measurement is required. Its design enables high accuracy and sensitivity, while its durability ensures reliable performance in demanding environments. As industries continue to prioritize efficiency and safety, the importance of such measurement instruments will only increase, solidifying the role of piston type differential pressure gauges in modern industrial processes.

By understanding the benefits and applications of these gauges, engineers and technicians can make informed choices for their pressure measurement needs, ultimately enhancing the safety and efficacy of industrial operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025