Oct . 31, 2024 05:59 Back to list

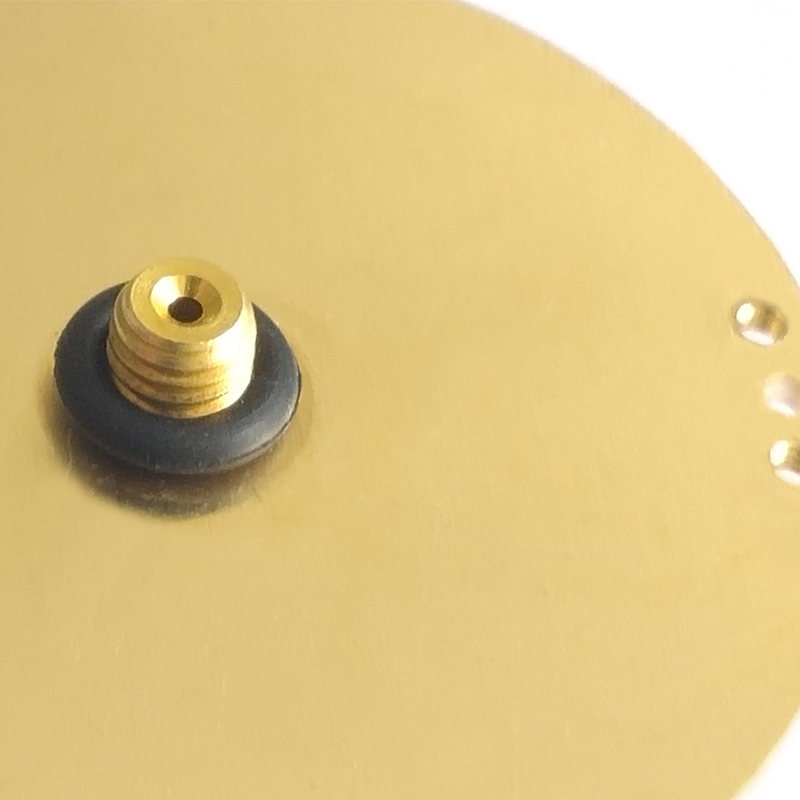

famous metallic diaphragm pressure gauge

The Importance of Famous Metallic Diaphragm Pressure Gauges in Industrial Applications

In various industrial settings, precision and reliability in measurement are crucial for ensuring safety and efficiency. Among the vital instruments used for measuring pressure, the metallic diaphragm pressure gauge stands out due to its robust design and exceptional performance. This article explores the significance of metallic diaphragm pressure gauges, their applications, and why they are favored in demanding environments.

Metallic diaphragm pressure gauges operate based on the deflection of a metallic diaphragm in response to pressure changes. When pressure is applied, the diaphragm deforms, and this movement is transmitted to a pointer that indicates the pressure reading on a calibrated dial. This design offers several advantages, making it a preferred choice in many industries.

One of the primary benefits of metallic diaphragm pressure gauges is their ability to withstand harsh environments. They are commonly made from stainless steel or other durable alloys, which provide excellent resistance to corrosion, high temperatures, and harsh chemicals. This resilience is essential in industries such as oil and gas, chemical processing, and pharmaceuticals, where exposure to aggressive substances is common.

Moreover, the mechanical simplicity of these gauges ensures high reliability and low maintenance requirements. Unlike electronic gauges, which may be susceptible to power fluctuations or electronic failures, metallic diaphragm gauges function purely on mechanical principles. This makes them less prone to failure, a crucial factor in industries where equipment downtime can lead to significant financial losses and safety hazards.

famous metallic diaphragm pressure gauge

In terms of accuracy, metallic diaphragm pressure gauges deliver dependable readings across a wide range of pressures. Their design allows for precise measurements, making them suitable for critical applications that require stringent pressure control. Whether monitoring the pressure in boilers, reactors, or piping systems, these gauges provide the confidence needed for optimal operation.

Another noteworthy aspect is the versatility of metallic diaphragm pressure gauges. They can be tailored to meet specific requirements, including different diaphragm materials, shapes, and sizes, depending on the application. This customization enables engineers to select the appropriate gauge to match the unique parameters of their system, ensuring maximum effectiveness.

Furthermore, advancements in manufacturing techniques have led to the development of innovations such as sealed diaphragm gauges. These are particularly beneficial in applications where the process medium might contaminate the measurement system. By isolating the diaphragm from the process fluid, sealed gauges help maintain accuracy and protect the integrity of the measurement system.

In conclusion, the famous metallic diaphragm pressure gauge is an indispensable tool in many industrial applications. Its robust construction, reliability, accuracy, and versatility make it an ideal choice for environments where precision and durability are paramount. As industries continue to evolve, the demand for dependable measurement solutions will only increase, and metallic diaphragm pressure gauges will remain at the forefront of this essential field. By ensuring accurate pressure monitoring, these gauges play a pivotal role in enhancing operational efficiency and safety across various sectors.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025