Nov . 05, 2024 08:10 Back to list

famous digital diaphragm pressure gauge

Understanding the Famous Digital Diaphragm Pressure Gauge

In the world of industrial measurement and control, precision is paramount. Among the myriad of tools available for monitoring pressure, the digital diaphragm pressure gauge stands out for its accuracy, reliability, and ease of use. This article delves into the features, applications, and advantages of using a digital diaphragm pressure gauge, highlighting its significance in various industries.

What is a Digital Diaphragm Pressure Gauge?

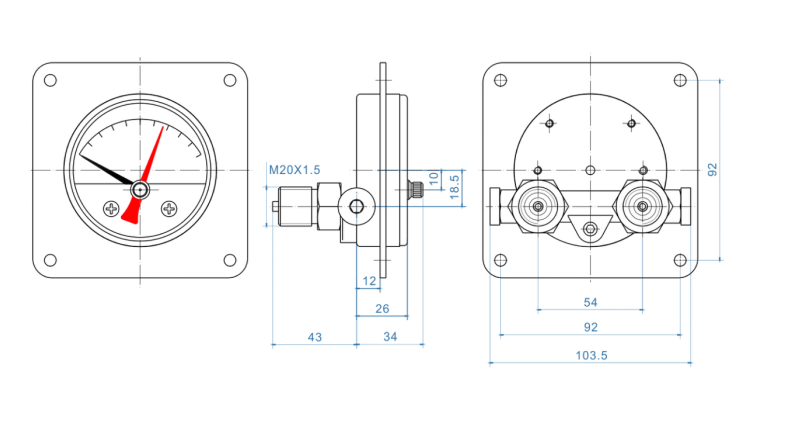

A digital diaphragm pressure gauge is a device designed to measure the pressure of gases or liquids. It employs a diaphragm that flexes under pressure, causing a sensor to convert the mechanical movement into an electrical signal. This signal is then processed and displayed on a digital interface, providing a clear and accurate reading of the pressure. The digital aspect enhances clarity, allowing for easy reading and interpretation of results compared to traditional analog gauges.

Key Features

1. High Accuracy Digital diaphragm pressure gauges are known for their high accuracy, often providing measurements within ±0.25% of the full scale. This precision is crucial in applications where minor fluctuations in pressure can have significant consequences.

2. Integrated Sensors These gauges often incorporate advanced sensor technology, enabling them to detect and measure both small and large pressure changes efficiently. This adaptability makes them suitable for a wide range of applications.

3. User-Friendly Interface The digital display typically includes features such as backlighting, adjustable units of measurement (psi, bar, kPa), and even data logging capabilities. Such features make it easier for users to monitor and analyze changes in pressure.

4. Robust Design Many digital diaphragm pressure gauges are built to withstand challenging environmental conditions, including extreme temperatures, vibrations, and corrosive substances. This durability ensures long service life and reliable performance.

famous digital diaphragm pressure gauge

Applications

Digital diaphragm pressure gauges have found their place in numerous industries, demonstrating versatility and effectiveness in various roles. Common applications include

- Oil and Gas Monitoring pressure in pipelines and storage tanks is crucial for safety and operational efficiency. - Pharmaceuticals Precise pressure measurement is essential in processes like fermentation and fluid transfer. - Water Treatment Ensuring appropriate pressure levels in treatment plants helps maintain system integrity and efficiency. - Manufacturing Pressure gauges are used to monitor processes in production lines, contributing to product quality and consistency.

Advantages Over Traditional Gauges

While analog gauges have been a staple in pressure measurement, digital diaphragm pressure gauges offer several advantages. The enhanced accuracy reduces the risk of errors, while the clear digital readouts simplify data interpretation. Additionally, features like programmable alarms can alert users to critical pressure changes, increasing safety and responsiveness.

Moreover, many digital gauges offer connectivity options, allowing integration with data logging systems for real-time monitoring and analysis. This technological advancement supports improved decision-making processes in industrial settings.

Conclusion

The digital diaphragm pressure gauge is an indispensable tool in various industries, providing enhanced accuracy, reliability, and user-friendliness. Its ability to deliver precise measurements combined with advanced features makes it a preferred choice among professionals. As industries continue to embrace technology for improved efficiency and safety, the relevance of the digital diaphragm pressure gauge will only grow, reinforcing its position as a critical instrument in modern measurement practices.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025