Nov . 08, 2024 04:55 Back to list

Innovative Diaphragm Technology for Accurate Differential Pressure Gauge Measurements

The Importance of Differential Pressure Gauges Focus on Diaphragm Technology

In various industrial applications, accurately measuring pressure is crucial for ensuring safety, efficiency, and process control. One essential instrument used in these scenarios is the differential pressure gauge. This device plays a vital role in monitoring the pressure difference between two points in a system, which can be critical for processes such as filtration, flow measurement, and level measurements.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. Unlike standard pressure gauges that measure pressure relative to the atmosphere, differential pressure gauges focus on the difference between two internal points in a system. This measurement can indicate various operational parameters such as flow rates across filters, blockage in pipes, or liquid levels in vessels.

Diaphragm Technology The Heart of Differential Pressure Gauges

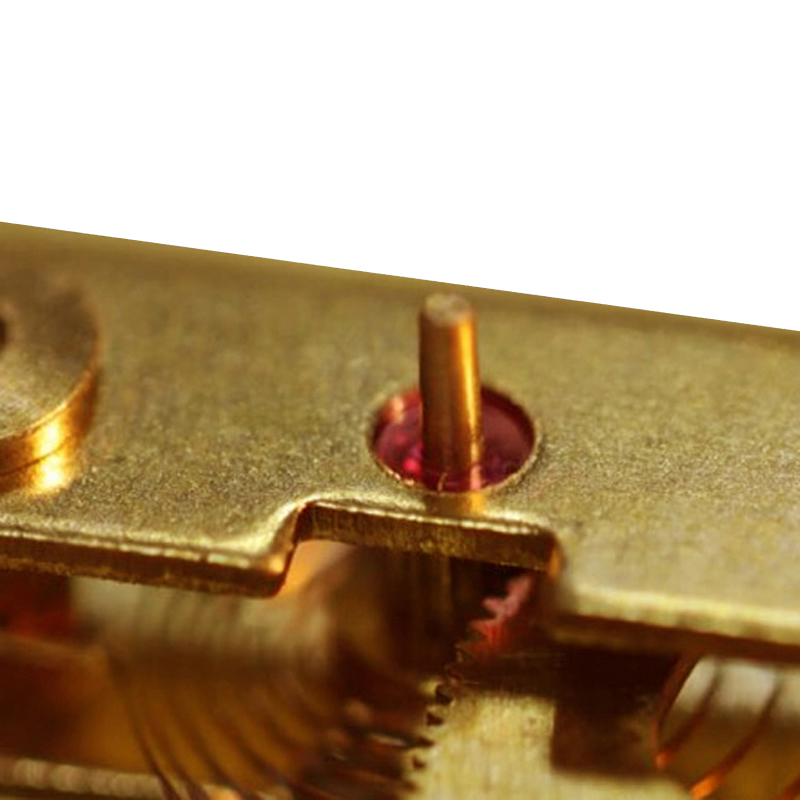

One of the most popular mechanisms used in differential pressure gauges is the diaphragm. A diaphragm-type gauge typically consists of a flexible membrane separating two pressure chambers. When pressure is applied to either side of the diaphragm, it deflects. The extent of this deflection directly correlates with the pressure difference being measured.

The diaphragm’s design can significantly impact the gauge’s performance. Common materials used for the diaphragm include stainless steel, polymers, and various elastomers. These materials are selected based on their compatibility with the process media, temperature ranges, and required accuracy.

Advantages of Diaphragm-Based Gauges

1. Sensitivity and Accuracy Diaphragm pressure gauges are known for their high sensitivity and accuracy. The flexible nature of the diaphragm allows for precise measurements even with small pressure differentials, making them suitable for delicate processes.

famous differential pressure gauge diaphragm

2. Durability Many diaphragm gauges are designed to withstand harsh conditions. The materials used can resist corrosion, abrasion, and other environmental factors, ensuring longevity and reliability.

3. Minimal Maintenance Since diaphragm-based gauges often have fewer moving parts than mechanical alternatives, they require less maintenance and are less prone to wear and tear. This aspect makes them a good choice for applications requiring constant monitoring without frequent downtime for servicing.

4. Versatility Diaphragm differential gauges can be used in a wide array of applications, including water treatment facilities, chemical processing plants, and HVAC systems. Their adaptability to various media and conditions further enhances their value in industrial scenarios.

Applications of Differential Pressure Gauges

Differential pressure gauges find their applications across many industries. In the oil and gas sector, these instruments are critical for monitoring pipeline pressures and ensuring safety in transportation. In water treatment plants, they help manage filter operations by signaling when a filter needs maintenance based on pressure drop.

Additionally, in the HVAC industry, differential pressure measurements assist in optimizing air flow and maintaining system efficiency. The gauges enable technicians to assess fan performance and duct integrity, contributing to energy savings and enhanced indoor air quality.

Conclusion

In conclusion, differential pressure gauges, particularly those utilizing diaphragm technology, offer significant advantages in various industrial applications. Their accuracy, durability, and versatility make them invaluable tools for ensuring optimal system performance and safety. As industries continue to evolve and push for greater efficiency, diaphragm-based differential pressure gauges will play a pivotal role in meeting these demands. Understanding and utilizing these instruments effectively can lead to improved operational control and reduced costs across diverse sectors.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025