Oct . 17, 2024 18:12 Back to list

famous diaphragm sealed pressure gauges

Understanding Famous Diaphragm Sealed Pressure Gauges

Diaphragm sealed pressure gauges are crucial instruments used across various industries to measure the pressure of gases and liquids. These specialized gauges utilize a flexible diaphragm to isolate the measuring element from the process medium, ensuring accurate readings while protecting the gauge from harsh conditions. Known for their reliability and precision, diaphragm sealed pressure gauges are highly favored for applications involving corrosive fluids, high viscosities, or extreme temperatures.

Structure and Functionality

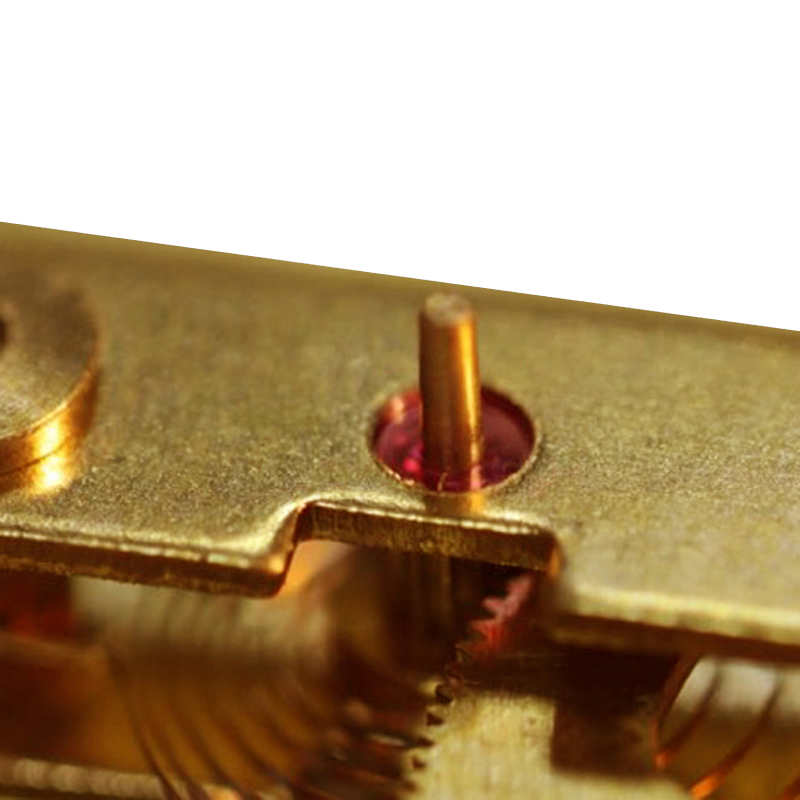

At the heart of diaphragm sealed pressure gauges is a diaphragm—typically made from materials such as stainless steel, PTFE (Teflon), or other elastomers—designed to flex under pressure. When pressure is applied, the diaphragm bows, causing a movement that translates into a measurable displacement. This movement is then converted into an electrical signal or mechanical output, according to the design of the gauge. The use of a sealed diaphragm allows for the isolation of the process fluid from the gauge mechanism, protecting it from contamination and damage.

The most prominent feature of these gauges is their ability to handle viscous and corrosive fluids, which would otherwise damage traditional gauges. By sealing the pressure sensing element, diaphragm sealed gauges can measure pressure accurately without being directly exposed to the media, making them invaluable in chemical processing, oil and gas, and food and beverage industries.

Types of Diaphragm Sealed Gauges

There are several types of diaphragm sealed pressure gauges, each designed to meet specific industry needs

1. Liquid-filled Gauges These gauges are filled with a damping liquid that minimizes the effects of vibrations and pulsations. The liquid provides lubrication, enhances accuracy, and extends the life of the gauge. Often used in applications with fluctuating pressures, such as HVAC systems and pumping stations, liquid-filled gauges improve performance and readability.

2. Mechanical Gauges These rely on mechanical principles for pressure measurement and are ideal for applications where electronic devices may not be suitable. Their simple design makes them robust and easy to maintain.

3. Digital Gauges With advancements in technology, digital diaphragm sealed gauges have emerged. These provide enhanced readability, data logging capabilities, and advanced features such as alarms and remote monitoring. Digital gauges are particularly popular in applications where precision and data management are critical.

Applications Across Industries

Diaphragm sealed pressure gauges find applications in various sectors, including

famous diaphragm sealed pressure gauges

- Chemical Industry Used for monitoring corrosive and toxic substances, they help ensure safe processing and handling in chemical plants. - Oil and Gas Sector They are adept at measuring pressures in drilling and refining processes, where fluids can be particularly harsh or contain solid particulates.

- Food and Beverage In this industry, cleanliness and the ability to measure viscous fluids are paramount. Diaphragm sealed gauges are designed to meet stringent sanitary standards, making them ideal for ensuring product quality and compliance.

- Pharmaceuticals Accurate pressure measurements are vital in the production of drugs. The sanitary design prevents contamination, ensuring that the end products are safe and effective.

Benefits of Diaphragm Sealed Pressure Gauges

The advantages of diaphragm sealed pressure gauges are numerous

- Protection from Contamination The sealed design keeps the gauge mechanism free from process media, extending its lifespan and reliability.

- Versatility They can be used in a wide variety of environments, from extreme temperatures to high-pressure conditions.

- Enhanced Safety By minimizing exposure to hazardous materials, diaphragm sealed gauges contribute to a safer workplace.

- Accuracy and Responsiveness These gauges provide quick and accurate readings, essential for real-time monitoring and control systems.

Conclusion

Famous diaphragm sealed pressure gauges play a vital role in numerous industrial applications, providing accurate and reliable pressure measurements. Their design offers numerous benefits, including protection from contamination, versatility in harsh environments, and enhanced safety. As technology continues to evolve, so will the capabilities of these essential instruments, further solidifying their importance in modern industry. Understanding their functionality and applications allows businesses to select the right gauge for their specific needs, optimizing efficiency and safety in their operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025