Dec . 12, 2024 11:37 Back to list

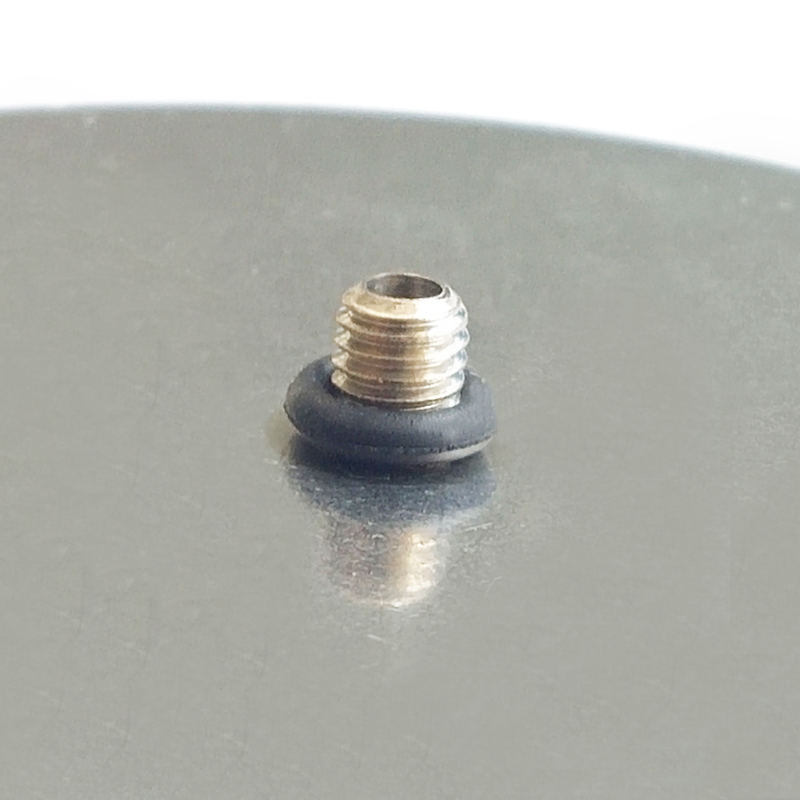

famous diaphragm protection pressure gauge

Understanding the Importance of Diaphragm Protection in Pressure Gauges

Pressure gauges are integral devices used across various industries to monitor and measure the pressure of gases and liquids. Among the different types of pressure gauges available, diaphragm pressure gauges have gained significant attention due to their robustness and reliability. The diaphragm protection mechanism enhances the performance and longevity of pressure gauges, ensuring accurate measurements in demanding environments.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge operates on the principle of measuring the deflection of a flexible diaphragm in response to pressure changes. The diaphragm is a thin membrane made from materials like stainless steel, bronze, or polymers, which allows it to move with fluid pressure variations. This movement translates into a readable output on the gauge dial, providing an accurate measurement of pressure.

The Role of Diaphragm Protection

Diaphragm protection is essential for ensuring the reliability and accuracy of pressure readings in tough operating conditions. The primary purpose of diaphragm protection is to safeguard the sensitive diaphragm element from damaging effects such as

1. Corrosive Fluids In many industrial applications, pressure gauges are exposed to aggressive chemicals that can erode or corrode the diaphragm material. Diaphragm protection uses various protective coatings or barrier systems that provide a shield against these harsh substances, reducing the risk of premature failure.

2. Viscous or Slurry Fluids When measuring the pressure of thick, viscous, or slurry fluids, traditional pressure gauges can become clogged, leading to inaccurate readings and increased maintenance costs. A diaphragm protection mechanism allows for better flow through the gauge, ensuring that the diaphragm remains responsive to pressure changes and minimizing the likelihood of blockages.

famous diaphragm protection pressure gauge

3. High Temperatures Elevated temperatures can affect the performance of pressure gauges. High thermal conditions can lead to the expansion of the diaphragm or even damage it. A well-designed diaphragm protection system can help to dissipate heat away from the measuring element, ensuring stability and accuracy in high-temperature applications.

4. Vibration and Pulsation In dynamic environments, such as those found in industrial machinery, pressure gauges can be subjected to constant vibrations and pressure fluctuations. Diaphragm protection can dampen these effects, ensuring that the gauge operates smoothly and delivers consistent readings despite challenging operating conditions.

Applications of Diaphragm Pressure Gauges

Diaphragm pressure gauges with protection mechanisms are widely used in various industries, including chemical processing, oil and gas, food and beverage, pharmaceuticals, and water treatment. Their ability to withstand harsh conditions and deliver precise measurements makes them suitable for critical applications where safety and reliability are paramount.

In the chemical industry, for instance, diaphragm pressure gauges are essential for monitoring reactor pressures and maintaining safe operating conditions. In the food and beverage sector, they are used to ensure proper pressure levels in processing systems, thus maintaining product quality and safety standards.

Conclusion

In conclusion, diaphragm pressure gauges equipped with protective mechanisms play a crucial role in ensuring accurate pressure measurement in demanding industrial environments. Their ability to withstand corrosive, viscous, and high-temperature conditions, as well as resist vibrations, makes them invaluable tools in various applications. Investing in high-quality diaphragm protection can significantly enhance the performance and reliability of pressure gauges, ultimately leading to improved operational efficiency and safety in the industries that rely on them. As industries continue to evolve and face new challenges, diaphragm protection remains a vital consideration for professionals seeking accuracy and durability in their pressure measurement solutions.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025