Jun . 14, 2024 03:02 Back to list

Famous Diaphragm Pressure Gauge.

The Famous Diaphragm Pressure Gauge A Historical and Technical Overview

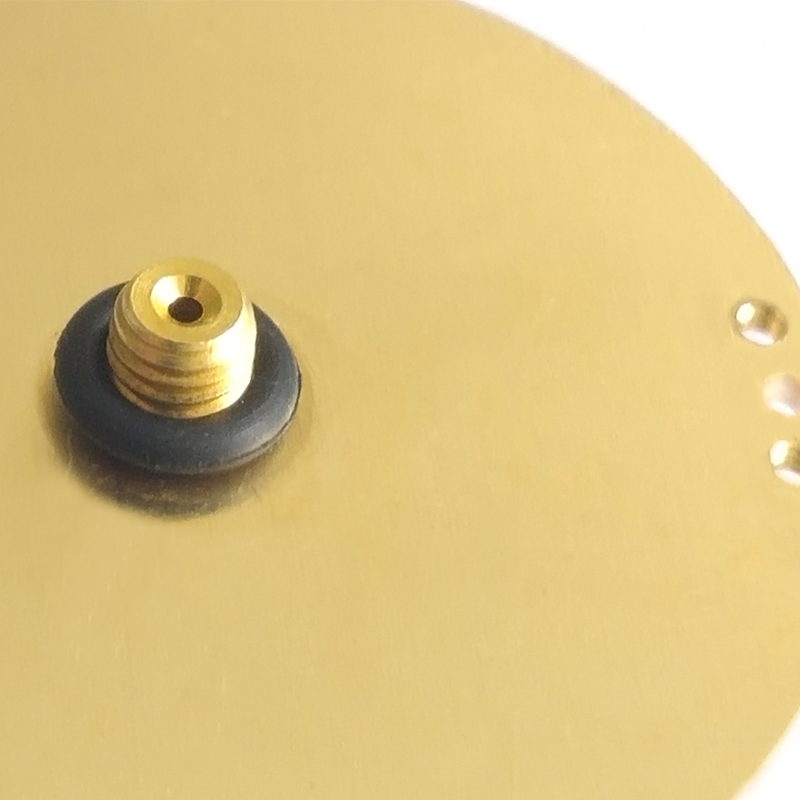

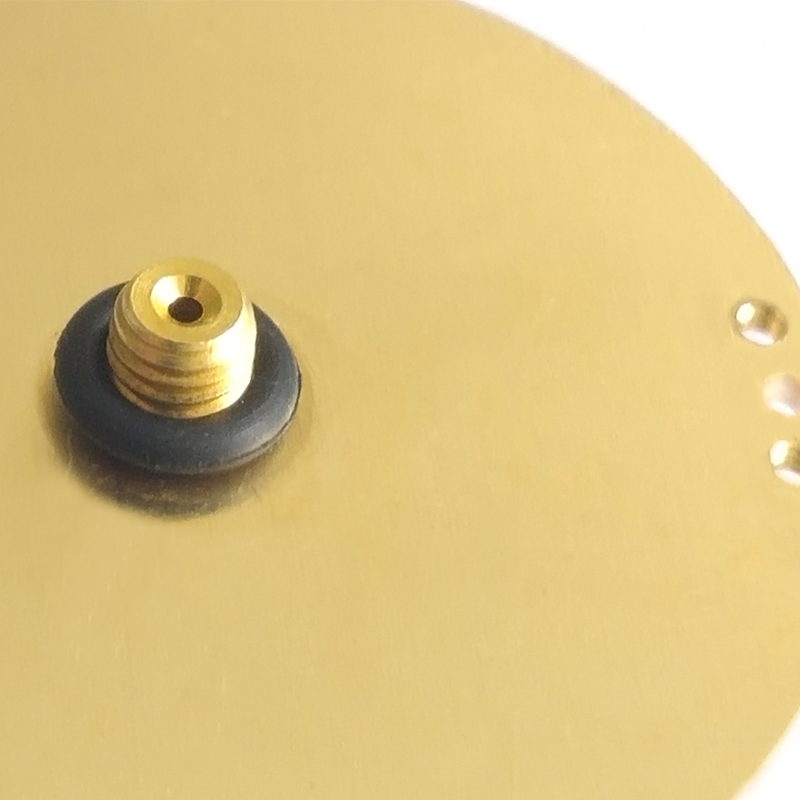

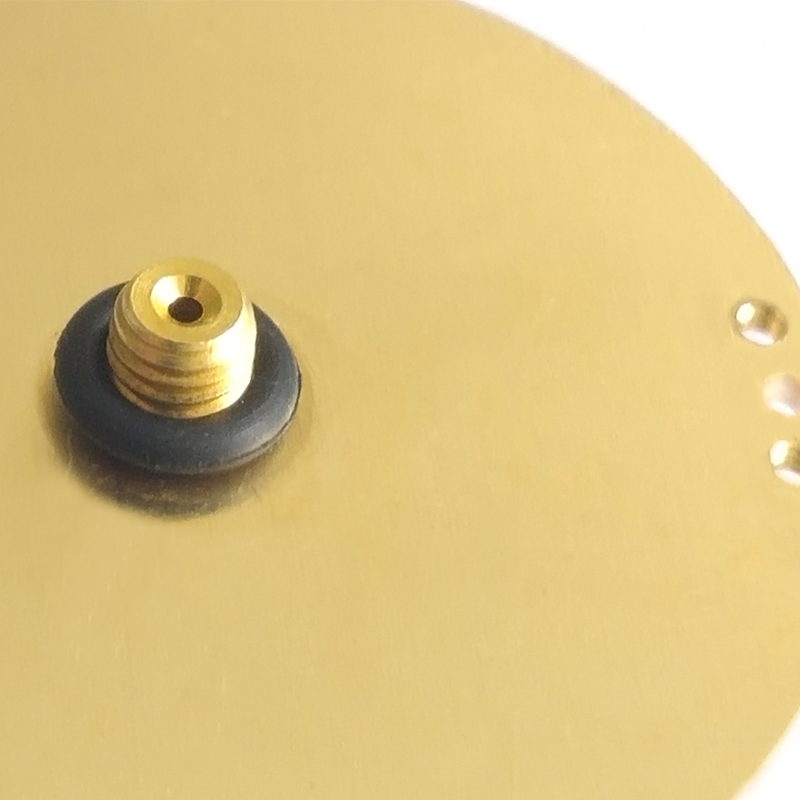

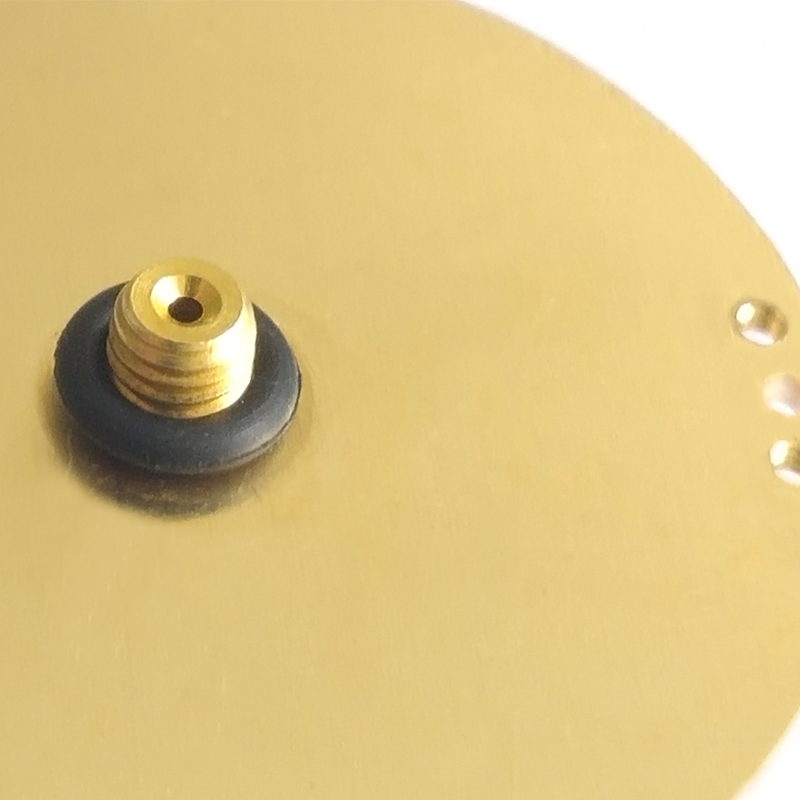

The diaphragm pressure gauge, a remarkable device that has played a significant role in various industries, is a testament to human ingenuity and innovation. This precision instrument, which measures pressure by utilizing the deflection of a flexible diaphragm, has a rich history that spans over a century.

Originating in the late 19th century, the diaphragm pressure gauge was initially developed for use in industrial processes. Its ability to accurately measure pressures in harsh environments, such as high temperatures and corrosive substances, made it an invaluable tool for engineers and scientists. Over time, its applications have expanded to include medical equipment, aerospace, and even household appliances.

One of the key factors that contributed to the success of the diaphragm pressure gauge is its simple yet effective design. The gauge consists of a metal or plastic case, a flexible diaphragm that separates the internal chamber from the external environment, and a sensing mechanism that measures the deflection of the diaphragm. When pressure is applied to the diaphragm, it deflects, and this deflection is converted into an electrical signal that can be read by a gauge or recorded by a computer.

The accuracy and reliability of the diaphragm pressure gauge have made it a popular choice in critical applications where precision is paramount. For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy

For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy famous diaphragm pressure guage. In the aerospace industry, it is employed to measure the pressure inside jet engines and ensure their safe operation.

Despite its many advantages, the diaphragm pressure gauge is not without its limitations. One of the main challenges is ensuring the long-term stability and reliability of the sensing mechanism, especially in extreme conditions. However, ongoing research and development efforts are aimed at addressing these issues and improving the performance of the gauge.

In conclusion, the diaphragm pressure gauge is a remarkable device that has stood the test of time. Its unique design, accuracy, and reliability have made it an indispensable tool in a wide range of applications. As technology continues to advance, we can expect to see further improvements and innovations in this field, making the diaphragm pressure gauge an even more valuable asset for humanity.

famous diaphragm pressure guage. In the aerospace industry, it is employed to measure the pressure inside jet engines and ensure their safe operation.

Despite its many advantages, the diaphragm pressure gauge is not without its limitations. One of the main challenges is ensuring the long-term stability and reliability of the sensing mechanism, especially in extreme conditions. However, ongoing research and development efforts are aimed at addressing these issues and improving the performance of the gauge.

In conclusion, the diaphragm pressure gauge is a remarkable device that has stood the test of time. Its unique design, accuracy, and reliability have made it an indispensable tool in a wide range of applications. As technology continues to advance, we can expect to see further improvements and innovations in this field, making the diaphragm pressure gauge an even more valuable asset for humanity.

For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy

For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy For example, in the medical field, it is used to monitor blood pressure and other vital signs with extreme accuracy famous diaphragm pressure guage. In the aerospace industry, it is employed to measure the pressure inside jet engines and ensure their safe operation.

Despite its many advantages, the diaphragm pressure gauge is not without its limitations. One of the main challenges is ensuring the long-term stability and reliability of the sensing mechanism, especially in extreme conditions. However, ongoing research and development efforts are aimed at addressing these issues and improving the performance of the gauge.

In conclusion, the diaphragm pressure gauge is a remarkable device that has stood the test of time. Its unique design, accuracy, and reliability have made it an indispensable tool in a wide range of applications. As technology continues to advance, we can expect to see further improvements and innovations in this field, making the diaphragm pressure gauge an even more valuable asset for humanity.

famous diaphragm pressure guage. In the aerospace industry, it is employed to measure the pressure inside jet engines and ensure their safe operation.

Despite its many advantages, the diaphragm pressure gauge is not without its limitations. One of the main challenges is ensuring the long-term stability and reliability of the sensing mechanism, especially in extreme conditions. However, ongoing research and development efforts are aimed at addressing these issues and improving the performance of the gauge.

In conclusion, the diaphragm pressure gauge is a remarkable device that has stood the test of time. Its unique design, accuracy, and reliability have made it an indispensable tool in a wide range of applications. As technology continues to advance, we can expect to see further improvements and innovations in this field, making the diaphragm pressure gauge an even more valuable asset for humanity. Share

Latest news

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025