Dec . 22, 2024 10:16 Back to list

explain diaphragm pressure gauge products

Understanding Diaphragm Pressure Gauge Products

Diaphragm pressure gauges are essential instruments in various industries, providing accurate measurements of pressure in gases and liquids. Their design and functionality make them suitable for many applications, offering advantages in durability, accuracy, and versatility. In this article, we will explore the principles behind diaphragm pressure gauges, their construction, applications, and the benefits they offer across different industries.

The Principle of Operation

Diaphragm pressure gauges operate based on the principle of a flexible diaphragm that deflects when subjected to pressure. This deflection is proportional to the pressure applied to the diaphragm. As the pressure increases, the diaphragm bends, causing a connected mechanical device (such as a needle or dial) to move, providing a visual representation of the pressure reading.

The diaphragm is typically made from materials such as stainless steel, Monel, or plastic, chosen for their resistance to corrosive environments and ability to withstand high pressures. This flexibility allows for precise measurements, as even minimal pressure changes can result in noticeable diaphragm movement.

Construction of Diaphragm Pressure Gauges

The construction of a diaphragm pressure gauge consists of several key components

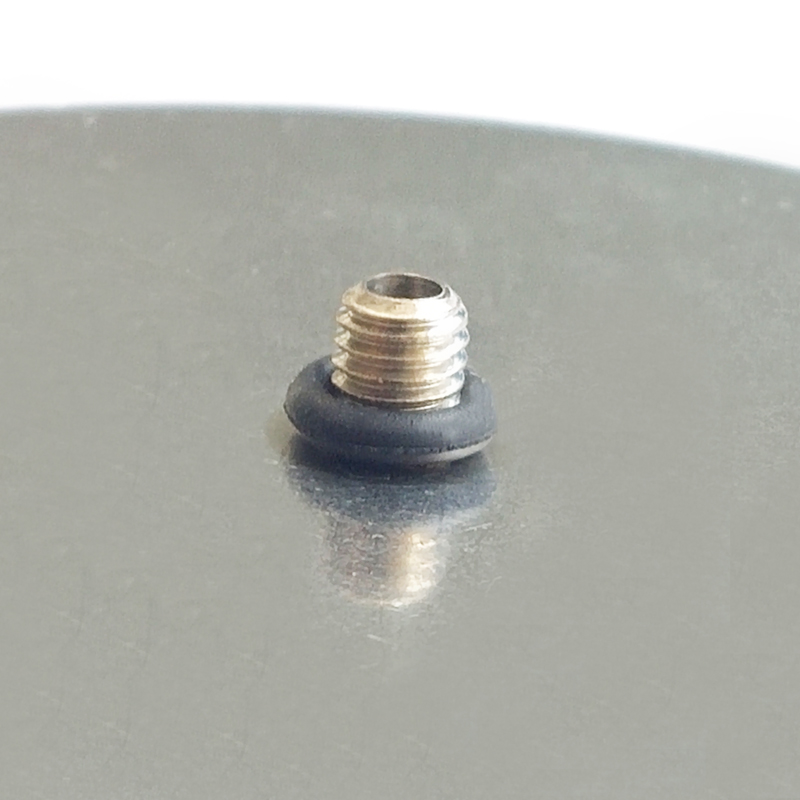

1. Diaphragm The heart of the gauge, the diaphragm can be designed in various shapes (e.g., flat, corrugated) depending on the application. The material selected also affects the gauge's compatibility with different media. 2. Pressure Chamber This enclosure houses the diaphragm and is connected to the pressure source. It often includes fittings for easy installation and removal.

3. Transmission Mechanism This component translates the diaphragm's movement into a readable pressure measurement. Common configurations include lever systems or gears.

4. Dial and Pointer The visible part of the gauge, the dial, and pointer display the pressure reading clearly. Dials are often calibrated in various units (PSI, bar, kPa) to cater to different user needs.

Applications of Diaphragm Pressure Gauges

explain diaphragm pressure gauge products

Diaphragm pressure gauges are used in numerous applications across various sectors, such as

- Oil and Gas Measuring pressure in pipelines and storage tanks to ensure safe and efficient operations. - Chemical Processing Monitoring pressure in reactors and vessels, where accurate pressure readings are crucial for safety and production quality. - Water Treatment Assessing pressure in filtration systems and treatment facilities to maintain the appropriate flow and prevent system failures. - Food and Beverage Ensuring consistent pressure in the processing and packaging stages, maintaining quality and safety standards. - HVAC Systems Measuring pressure in heating, ventilation, and air conditioning systems to optimize performance.

Benefits of Using Diaphragm Pressure Gauges

The advantages of diaphragm pressure gauges make them a preferred choice in many applications

1. Durability Built with robust materials, diaphragm gauges can withstand harsh environments, including exposure to chemicals and extreme temperatures.

2. Accuracy Due to their sensitive design, these gauges provide precise readings, enabling users to make informed decisions based on reliable data.

3. Versatility Suitable for measuring both gases and liquids, diaphragm gauges can accommodate a wide range of applications, expanding their usability across industries.

4. Safety By accurately monitoring pressure, diaphragm gauges help prevent system failures and dangerous situations, contributing to workplace safety.

5. Low Maintenance Once installed, diaphragm pressure gauges typically require minimal maintenance, reducing operational costs and downtime.

Conclusion

Diaphragm pressure gauges are vital tools in many industrial applications, recognized for their accuracy, durability, and versatility. By understanding how these instruments work and the benefits they provide, industries can enhance their operations, ensuring safety and efficiency. As technology continues to evolve, diaphragm pressure gauges will undoubtedly play a crucial role in industrial measurement and control systems, adapting to meet the new challenges of a rapidly changing world.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025