Sep . 22, 2024 12:05 Back to list

duplex differential pressure gauge factory

Understanding Duplex Differential Pressure Gauges A Comprehensive Overview

In various industrial sectors, maintaining optimal operational efficiency and ensuring safety are paramount. One of the critical tools aiding these objectives is the duplex differential pressure gauge. This instrument serves a crucial role in monitoring pressure differences between two points in a system, which can be vital for various processes such as filtration, flow measurement, and pressure drop assessment.

A duplex differential pressure gauge is distinguished by its ability to display the differential pressure from two separate points simultaneously. This feature is incredibly advantageous in applications requiring real-time monitoring and immediate response to pressure changes. By utilizing two pressure sensors, the gauge provides a clear visual representation of the pressure difference via dual dials or digital displays, allowing operators to ensure that systems are functioning within their specified parameters.

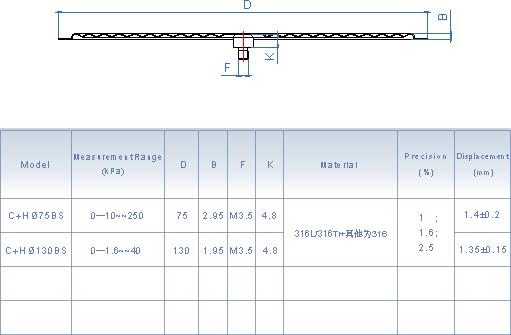

The construction of a duplex differential pressure gauge usually includes robust materials designed to withstand harsh environments. This is essential in industries like oil and gas, chemical processing, and water treatment, where the conditions can be extreme. High-quality materials, combined with precision engineering, result in durable gauges that can deliver accurate readings over extended periods.

duplex differential pressure gauge factory

One of the significant advantages of duplex differential pressure gauges is their ability to enhance operational reliability. By continuously monitoring pressure differences, these gauges help detect potential system failures before they escalate into more serious issues. For instance, in filtration systems, a sudden increase in differential pressure can indicate filter clogging, prompting maintenance before a complete shutdown occurs. This proactive approach can save both time and money while minimizing downtime and service interruptions.

Moreover, the versatility of duplex differential pressure gauges makes them suitable for a wide range of applications. They can be employed in HVAC systems to monitor air pressure across filters and ducts, in hydraulic circuits to assess pump performance, or in pharmaceutical manufacturing for ensuring proper flow rates during production processes. Their adaptability to various industries underscores their importance in modern engineering.

When selecting a duplex differential pressure gauge, several factors must be considered, including the measurement range, accuracy, and environmental conditions. Additionally, potential users should evaluate the gauge’s compatibility with the fluids involved in the processes to ensure durability and reliability over time.

In conclusion, duplex differential pressure gauges are indispensable tools in today’s industrial landscape. Their ability to monitor pressure differences in real-time not only enhances safety and efficiency but also facilitates proactive maintenance strategies across various applications. As industries continue to evolve, the importance of precise and reliable pressure monitoring will remain a cornerstone of operational excellence, making duplex differential pressure gauges a critical component in achieving those objectives.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025