Nov . 10, 2024 14:44 Back to list

Innovative Digital Diaphragm Pressure Gauges for Accurate Measurement and Monitoring Solutions

Understanding Digital Diaphragm Pressure Gauge Products

Digital diaphragm pressure gauges have become essential instruments in various industrial applications due to their accuracy, reliability, and ease of use. These devices play a crucial role in measuring and monitoring pressure in different systems, making them indispensable in fields such as manufacturing, HVAC, automotive, and more. This article aims to explore the features, advantages, and applications of digital diaphragm pressure gauge products.

What is a Digital Diaphragm Pressure Gauge?

A digital diaphragm pressure gauge consists of a diaphragm that deflects in response to pressure changes. This deflection is then converted into an electronic signal that is displayed numerically on a digital readout. The digital format not only allows for more precise readings but also provides enhanced features such as data logging, alarm settings, and often interface capabilities for integration with other equipment.

Key Features of Digital Diaphragm Pressure Gauges

1. Accuracy Digital diaphragm pressure gauges provide high levels of accuracy and can detect even small changes in pressure, making them suitable for sensitive applications.

2. Digital Display The easy-to-read digital display eliminates ambiguity associated with traditional analog gauges. Users can quickly interpret readings without the potential for parallax errors, which can occur with analog dials.

3. Robust Construction Many digital diaphragm pressure gauges are designed to withstand harsh environments. They often feature rugged housings, corrosion-resistant materials, and are capable of functioning in extreme temperatures.

4. Calibration and Zero Adjustment Digital gauges typically come with the capability for easy calibration and zero adjustments, allowing users to maintain accuracy over time.

5. Data Logging and Connectivity Many modern digital gauges come equipped with data logging capabilities, enabling users to record pressure readings for later analysis. Furthermore, some models feature connectivity options such as USB, Bluetooth, or Wi-Fi, allowing real-time data monitoring and remote access.

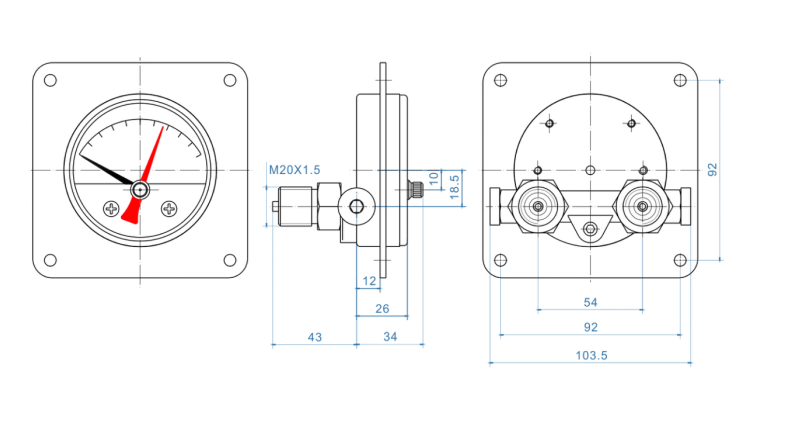

digital diaphragm pressure gauge products

Advantages of Digital Diaphragm Pressure Gauges

1. Ease of Use The straightforward user interface of digital gauges makes them convenient for operators of all skill levels. The instant readability reduces the chance of human error in interpreting the gauge.

2. Maintenance Digital diaphragm pressure gauges require less maintenance compared to traditional gauges, as they have fewer moving parts that can wear out.

3. Versatility These gauges can be used in various applications, from simple hydraulic systems to complex industrial processes, ensuring that they can meet diverse operational needs.

4. Safety Features Many digital models incorporate safety features like overpressure alarms, which can alert operators to potentially dangerous conditions before they escalate.

Applications

Digital diaphragm pressure gauges find applications in numerous industries. In the oil and gas sector, they are used to monitor pipeline pressures and ensure operation within safe limits. In the food and beverage industry, these gauges help maintain required pressure levels in processing equipment, contributing to product quality and safety. HVAC systems utilize them to monitor air and fluid pressures, ensuring efficient operation of heating and cooling systems. Furthermore, they are crucial in laboratory settings for precise pressure measurements.

Conclusion

In conclusion, digital diaphragm pressure gauges are invaluable tools in the modern industrial landscape, offering accuracy, reliability, and user-friendly features. As technology continues to advance, these products will likely become even more sophisticated, integrating with smart systems and digital networks to enhance monitoring and control capabilities. For businesses looking to optimize their operations, investing in a high-quality digital diaphragm pressure gauge can lead to improved safety, efficiency, and overall productivity. As industries evolve, so too will the demand for these superior measuring instruments.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025