Oct . 10, 2024 07:09 Back to list

differential pressure gauge suppliers product

Understanding Differential Pressure Gauges and Their Suppliers

Differential pressure gauges are essential instruments used in various industries for measuring the difference in pressure between two points. These devices are crucial for ensuring the efficiency and safety of processes in settings such as oil and gas, water treatment, HVAC systems, and more. With the increasing demand for precise pressure measurements, numerous suppliers have emerged, each offering a wide range of products tailored to specific applications.

What is a Differential Pressure Gauge?

A differential pressure gauge works by measuring the pressure difference between two pressure ports. One port is connected to a higher pressure source, while the other connects to a lower pressure area. The gauge displays this difference, allowing operators to monitor the flow of liquids and gases in pipelines, tanks, and reactors. These measurements can indicate blockage in pipes, filter conditions, or fluid flow rates, making them invaluable in maintaining operational efficiency.

Applications of Differential Pressure Gauges

Differential pressure gauges find applications across various sectors. In the oil and gas industry, they monitor pipeline integrity and fluid flow, ensuring that operations run smoothly without leaks. In HVAC systems, they help manage the airflow in ducts, optimizing energy usage and maintaining indoor air quality. Water treatment facilities utilize these gauges to control processes, such as filtration and chemical dosing, ensuring that water quality meets safety standards.

Types of Differential Pressure Gauges

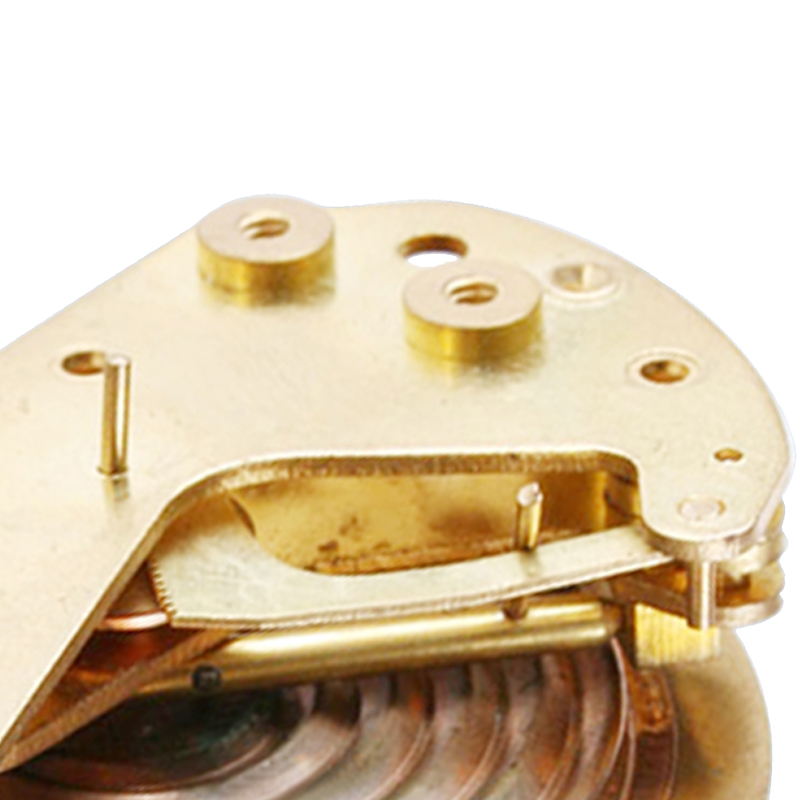

There are several types of differential pressure gauges available in the market, catering to different environments and requirements. Mechanical gauges, often referred to as Bourdon tube gauges, use a flexible metal tube that deforms under pressure changes, providing a direct readout. Digital gauges, on the other hand, offer enhanced accuracy and are equipped with features like remote monitoring and data logging.

Some gauges are designed for specific conditions, such as sanitary applications in the food and beverage industry, where hygiene is critical. Others are built to withstand harsh environments, like those found in chemical plants or oil rigs, where exposure to corrosive materials is a concern. Understanding the specific requirements of an application is crucial when selecting the appropriate gauge.

Finding Reliable Suppliers

differential pressure gauge suppliers product

As demand for differential pressure gauges has grown, so has the number of suppliers. A reputable supplier will offer high-quality products that meet relevant industry standards. When searching for differential pressure gauge suppliers, consider the following factors

1. Product Range Look for suppliers that provide a broad selection of differential pressure gauges, including mechanical and digital types, as well as specialized models for unique applications.

2. Quality and Certification Ensure that the products meet international quality standards, such as ISO certification. This is especially important in industries like oil and gas, where safety is paramount.

3. Technical Support A good supplier should offer excellent customer service and technical support. This includes assistance with product selection, installation, and troubleshooting.

4. Reputation Research the reputation of the supplier within the industry. Customer reviews and testimonials can provide insight into their reliability and product quality.

5. Pricing While quality is vital, pricing also plays a crucial role in decision-making. Compare prices among different suppliers, but be wary of choosing the cheapest option without considering quality.

6. Customization Options Some suppliers may offer customization capabilities for their gauges, which can be essential for unique applications.

Conclusion

Differential pressure gauges are critical tools in various industries, providing essential data for process control and safety monitoring. With many suppliers available, it is important for businesses to choose the right partner who can deliver high-quality products and support. By understanding the types of differential pressure gauges and their applications, as well as evaluating potential suppliers on several criteria, companies can make informed decisions to enhance their operational efficiency and safety. Whether for routine monitoring or specialized applications, the right differential pressure gauge can significantly impact outcomes in any industrial setting.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025