Dec . 24, 2024 15:25 Back to list

Differential Pressure Gauge Manufacturer for Accurate Measurement Solutions

Understanding Differential Pressure Gauge Suppliers and Factories

Differential pressure gauges play a crucial role in various industries such as oil and gas, water treatment, pharmaceuticals, and HVAC systems. These instruments measure the difference in pressure between two points in a system, enabling operators to monitor flow rates, filter conditions, and overall system health. As the demand for precise measurement continues to rise, selecting a reliable differential pressure gauge supplier is pivotal for maintaining operational efficiency.

The Importance of Differential Pressure Gauges

In many processes, measuring differential pressure is essential for ensuring safety and efficiency. For instance, in a filtration system, if the differential pressure across the filter rises significantly, it may indicate that the filter is becoming clogged and requires maintenance. Similarly, in a HVAC system, monitoring the differential pressure can ensure that airflow is within acceptable ranges, contributing to better energy efficiency and comfort.

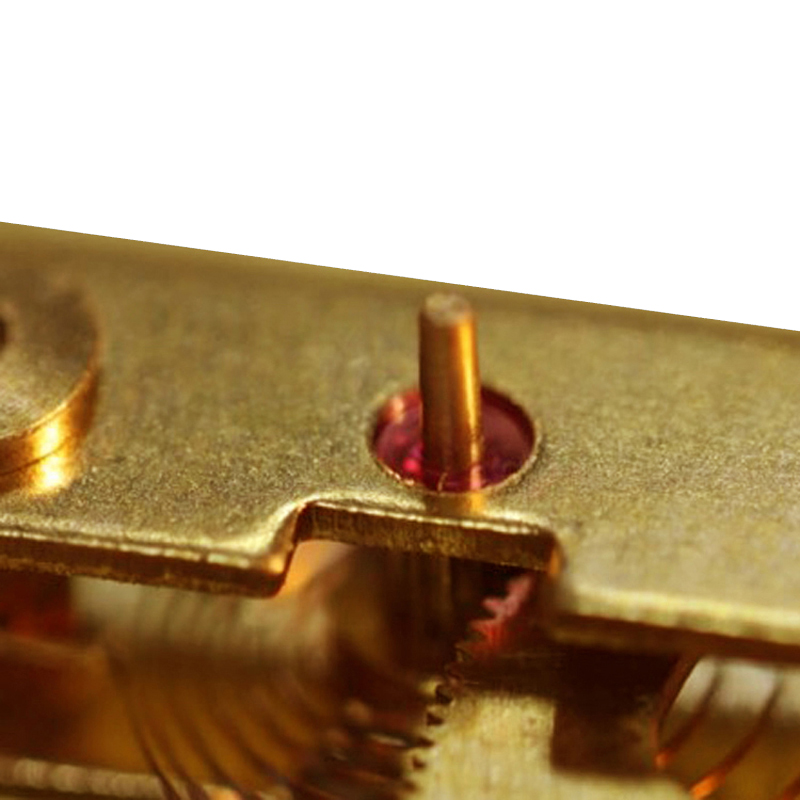

Differential pressure gauges come in various forms, including mechanical gauges, electronic sensors, and digital readouts. Some technologies use diaphragms, while others utilize strain gauges. The choice of technology and the supplier can affect the gauge's accuracy, reliability, and longevity.

Selecting a Differential Pressure Gauge Supplier

When looking for a differential pressure gauge supplier, several factors should be considered

1. Quality and Reliability The supplier's reputation in producing high-quality gauges is essential. Reviews and testimonials from other customers can provide insight into the reliability of the products. Additionally, suppliers that adhere to international standards (like ISO or ANSI) ensure that their products meet stringent quality requirements.

2. Customization Options Different applications may require unique specifications, such as range, material compatibility, or size. A good supplier should offer customization options to cater to specific industry needs. This ensures that the gauge integrates seamlessly into an existing system, maintaining accuracy and functionality.

differential pressure gauge supplier factory

3. Technical Support and Service The need for post-purchase support cannot be overstated. A competent supplier will provide technical assistance during installation and offer guidance on maintenance and troubleshooting. Good customer service can significantly reduce downtime and prevent costly errors.

4. Warranty and After-Sales Service A solid warranty reflects the confidence a supplier has in their product. It also protects the buyer’s investment. Additionally, a reliable after-sales service is essential for ensuring longevity and consistent performance.

5. Inventory and Lead Time Supplier factories should maintain a well-stocked inventory and be capable of fulfilling orders promptly. Long lead times can hamstring projects and disrupt workflows. An efficient supplier will ensure quick turnaround times to meet urgent demands.

The Role of Factories in Production

Modern factories manufacturing differential pressure gauges utilize advanced technologies such as automated assembly lines and quality control systems to enhance production efficiency. Factories should be equipped with state-of-the-art equipment to produce gauges that are accurate and durable. Continuous research and development within these facilities also contribute to innovations in gauge technology, leading to improved accuracy and new features.

Moreover, sustainable manufacturing practices are becoming increasingly important for suppliers. Factories that prioritize eco-friendly processes not only contribute to environmental conservation but also enhance their brand reputation among consumers who are becoming more conscious of sustainability.

Conclusion

Choosing the right differential pressure gauge supplier and factory is critical for ensuring operational efficiency and safety across various industries. By considering factors such as quality, customization, support, warranty, and manufacturing practices, businesses can make informed decisions that benefit their processes in the long run. In an age where precision and reliability are paramount, investing in quality differential pressure gauges from a reputable supplier is a step towards achieving operational excellence.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025