Dec . 05, 2024 12:59 Back to list

Top Manufacturers of Differential Pressure Gauges and Their Latest Quotes

Understanding Differential Pressure Gauges A Guide for Buyers

Differential pressure gauges are critical instruments used in various industrial applications to measure the difference in pressure between two points in a system. These gauges play a vital role in monitoring, controlling, and optimizing processes in industries such as oil and gas, water treatment, HVAC (heating, ventilation, and air conditioning), and pharmaceuticals. As industries continue to evolve and demand for precise measurement instruments grows, it’s essential for buyers to understand the key features, benefits, and considerations when evaluating quotes from differential pressure gauge manufacturers.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the pressure difference between two points within a system, which can help identify blockages, leaks, and flow rates. This measurement is crucial for ensuring operational efficiency and safety. For example, in HVAC systems, monitoring the pressure difference across an air filter can determine when the filter needs servicing or replacement.

Types of Differential Pressure Gauges

Differential pressure gauges generally fall into three main categories

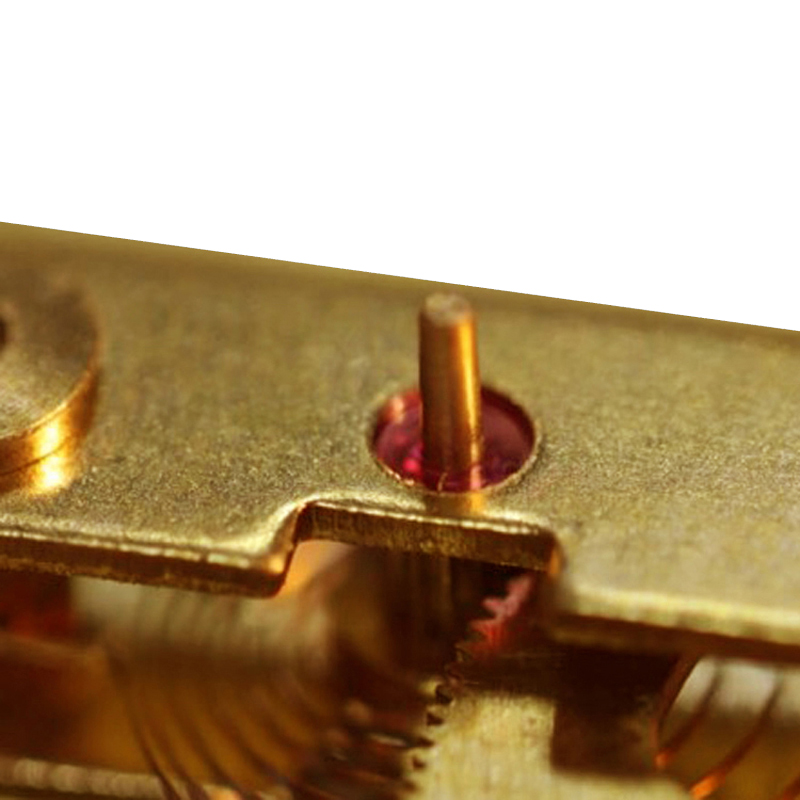

1. Mechanical Gauges These include Bourdon tube and diaphragm gauges that physically move in response to pressure changes. They are reliable for many applications and do not require external power.

2. Electronic Gauges Utilizing sensors and digital displays, electronic gauges provide precise measurements and may include features such as data logging and remote monitoring capabilities.

3. Liquid-filled Gauges These gauges contain a viscous fluid that dampens vibrations, providing a steady reading in turbulent environments. They are ideal for applications with fluctuating pressures.

Key Features to Consider

When receiving quotes from manufacturers, it’s essential to evaluate the following features

differential pressure gauges manufacturers quotes

- Accuracy Different applications demand various levels of precision. Ensure that the quoted gauge meets the specific accuracy requirements of your process.

- Range Assess the pressure range of the gauge. The suitable gauge for high-pressure systems may differ significantly from those used in low-pressure applications.

- Material and Construction The gauge's material should be compatible with the media being measured to prevent corrosion and ensure longevity. Consider factors like temperature resistance and pressure conditions.

- Size and Mounting Options Evaluate the installation space and select a gauge that fits appropriately. Manufacturers may offer various mounting options like panel mounting, direct mounting, or via standoffs.

- Calibration and Certification Verify if the manufacturer provides calibration services and certifications, which may be necessary for regulatory compliance in certain sectors.

The Importance of Manufacturer Reputation

When examining quotes, prioritize manufacturers with a solid reputation in the industry. Well-known manufacturers often provide robust warranties, reliable customer support, and extensive product knowledge. Look for reviews and testimonials or ask for references to ascertain the manufacturer's reliability and quality.

Price Considerations

While cost is an important consideration, it should not be the sole deciding factor. A lower price may correspond to lower quality or fewer features. Consider the value offered, including durability, accuracy, and support services. In many cases, investing a bit more in a high-quality gauge can result in long-term savings by reducing downtime and maintenance costs.

Conclusion

Choosing a differential pressure gauge is a critical decision that can impact operational efficiency across various industries. By understanding the types, features, and important factors to consider when evaluating manufacturer quotes, buyers can make informed decisions that align with their operational needs. Remember, prioritizing quality and reliability can lead to better performance and ultimately, successful operational outcomes. Thus, taking the time to examine quotes and select the right manufacturer is essential for maintaining the integrity of your processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025