Nov . 21, 2024 03:51 Back to list

differential pressure gauges manufacturers exporter

Differential Pressure Gauges An Overview of Manufacturers and Exporters

Differential pressure gauges are crucial instruments used in various industrial applications to measure the difference in pressure between two points in a system. These gauges are essential for monitoring processes in industries such as oil and gas, water treatment, pharmaceuticals, and HVAC systems. With the growing demand for efficient pressure monitoring solutions, the market for differential pressure gauges has expanded, leading to an increase in both manufacturers and exporters. This article delves into the world of differential pressure gauge manufacturers and exporters, highlighting their importance and implications in the industry.

Understanding Differential Pressure Gauges

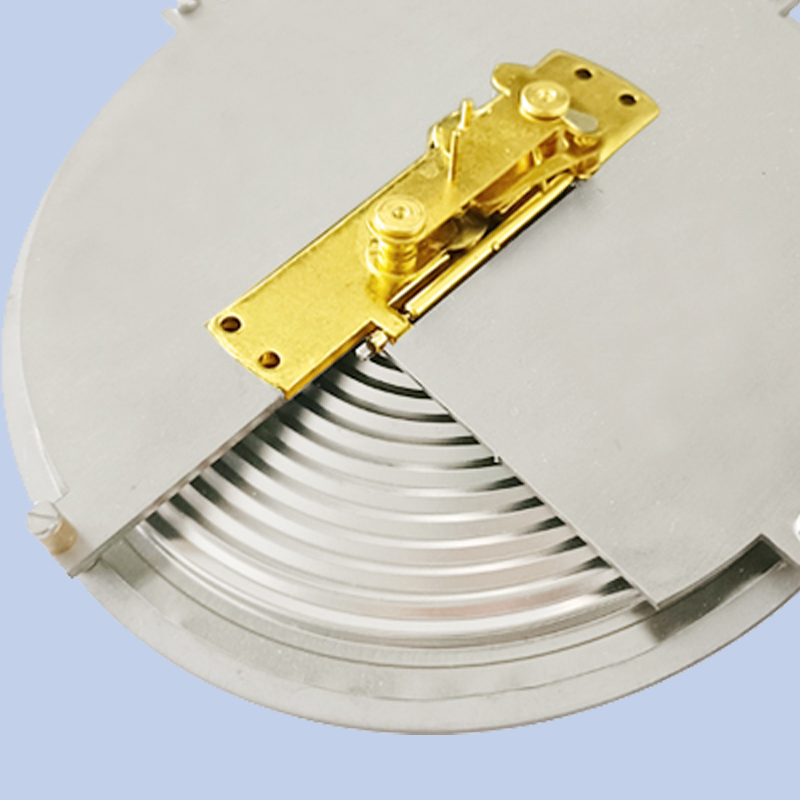

Differential pressure gauges function by measuring the pressure difference between two points. This measurement enables users to monitor flow rates, filter conditions, and fluid levels, thereby ensuring that systems operate efficiently and safely. These gauges can be analog or digital and can work with different fluids, including gases and liquids.

Analog gauges use mechanical components and can be easier to read in certain conditions, while digital gauges provide more precise readings and can include features like data logging and remote monitoring. The choice between the two often depends on specific applications and user preferences.

Manufacturers of Differential Pressure Gauges

The manufacturing industry for differential pressure gauges is characterized by a diverse range of companies, each specializing in different types of gauges to meet various industrial needs

. Renowned manufacturers are often distinguished by their commitment to quality, innovation, and customer service.Some well-known manufacturers are based in regions with a strong industrial base, such as North America, Europe, and Asia. These companies invest heavily in research and development to produce gauges that not only meet but exceed industry standards. They often utilize advanced materials and manufacturing techniques to enhance the durability and reliability of their products.

differential pressure gauges manufacturers exporter

For instance, many manufacturers incorporate features such as corrosion resistance, temperature stability, and enhanced accuracy to cater to specific industrial requirements. This push for quality and innovation has fostered a competitive market, benefiting consumers with a wider selection of high-performance gauges.

Exporters of Differential Pressure Gauges

As the global demand for differential pressure gauges rises, the role of exporters has become increasingly significant. Exporters facilitate the distribution of these instruments across borders, allowing access to a broader range of markets. Countries with advanced manufacturing capabilities often emerge as key players in the export sector, supplying high-quality gauges to regions where local production may be limited.

Exporters typically collaborate with various stakeholders, including manufacturers, to ensure that they provide products that meet international standards. They play a crucial role in logistics, ensuring timely delivery and compliance with regulatory requirements in different countries.

Moreover, many exporters focus on building long-term relationships with their clients, offering tailored solutions and support services to enhance customer satisfaction. This approach not only fosters trust but also helps exporters gain insights into emerging market trends, enabling them to adapt their offerings accordingly.

The Future of Differential Pressure Gauge Manufacturing and Exporting

The future of differential pressure gauges looks promising, driven by technological advancements and increasing industrial automation. Innovations such as IoT integration and smart gauges that provide real-time data are set to revolutionize the industry. As industries continue to prioritize efficiency and safety, the demand for reliable differential pressure gauges will undoubtedly continue to grow.

In conclusion, differential pressure gauges play a vital role in numerous industrial processes, and the ecosystem of manufacturers and exporters is essential in delivering these critical instruments. As the industry evolves, both manufacturers and exporters must continue to innovate and adapt to meet the dynamic needs of the global market. With a focus on quality, reliability, and customer support, they will continue to be key players in ensuring efficient and safe industrial operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025