Sep . 30, 2024 11:02 Back to list

Differential Pressure Gauge Price List from Various Manufacturers and Suppliers

Understanding Differential Pressure Gauge Pricing A Comprehensive Overview

Differential pressure gauges are essential instruments used in various industries to measure the difference in pressure between two points. They play a crucial role in monitoring and controlling processes in applications such as HVAC systems, oil and gas, pharmaceuticals, and water treatment. Given their importance, understanding the pricing of differential pressure gauges and the factors that influence their cost is critical for manufacturers, engineers, and procurement specialists.

Key Factors Influencing Differential Pressure Gauge Prices

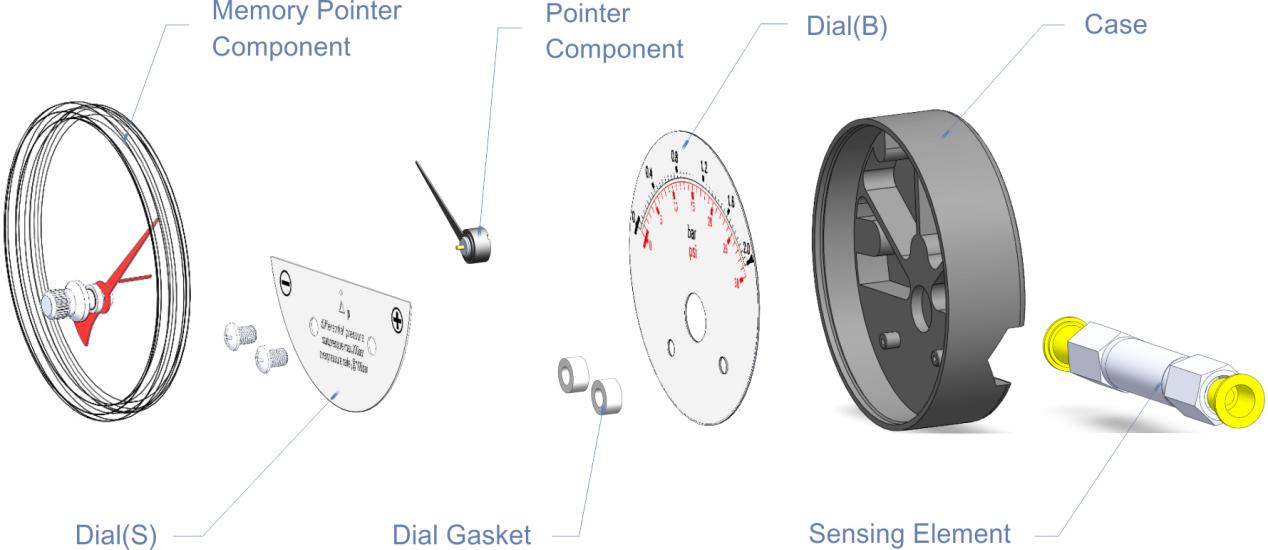

1. Type of Gauge Differential pressure gauges come in several types, including mechanical (bourdon tube, diaphragm, and capsule) and electronic (capacitance, piezoresistive, and strain gauge). Mechanical gauges are generally less expensive than electronic gauges, but the latter provide enhanced accuracy, real-time data, and advanced features, which can significantly increase their price.

2. Material Composition The materials used in the construction of the gauge impact its durability and performance. Gauges made from high-quality stainless steel or special alloys typically cost more due to their resistance to corrosion and ability to withstand harsh environments.

3. Range and Accuracy Gauges are available in a variety of pressure ranges and accuracy levels. Instruments that can measure extremely low or high pressures, or those that provide high precision, often come with a higher price tag. Consequently, it is essential to match the gauge specifications to the application requirements without overspending on unnecessary features.

4. Manufacturer Reputation Established manufacturers with a proven track record tend to charge more for their products. This often correlates with higher reliability, better customer service, and guarantees of product performance. Choosing a reputable manufacturer can be a safeguard against failures and associated costs, making a higher initial investment worthwhile.

5. Project-Specific Customizations Some applications may require customized solutions, such as specific connections, special materials, or enhanced temperature specifications. Customization often entails additional engineering and manufacturing efforts, which can significantly increase the gauge's price.

differential pressure gauge price list manufacturers

6. Volume Purchases and Discounts Manufacturers and suppliers often provide discounts for bulk purchases. If your organization requires numerous gauges for a project, negotiating with suppliers or purchasing in larger quantities can lead to substantial savings.

Average Pricing Insights

As of 2023, the price range for differential pressure gauges can vary significantly. Basic mechanical gauges might be found for as low as $50 to $200. Standard electronic gauges typically range from $200 to $1,000, while high-end models with advanced features might cost anywhere from $1,000 to $5,000 or more. It's crucial to obtain a detailed price list from manufacturers, as prices can vary based on the factors previously discussed.

Market Trends

In recent years, the demand for differential pressure gauges has increased, particularly in the fields of environmental monitoring and industrial automation. This rising demand has prompted innovations in gauge technology, leading to more advanced, accurate, and cost-effective solutions. Manufacturers are also focusing on integrating IoT capabilities into gauges, allowing for remote monitoring and data analysis, which can justify higher pricing due to improved operational efficiencies.

Conclusion

Investing in a differential pressure gauge is a decision that can significantly impact the operational effectiveness of industrial processes. Understanding the various factors that influence the price of these instruments enables businesses to make informed purchasing decisions. By considering the type, materials, accuracy, manufacturer, and potential bulk discounts, organizations can ensure they select the right gauges at competitive prices.

Whether for an immediate project need or long-term operational monitoring, having a comprehensive understanding of the pricing landscape and product offerings will facilitate better investment decisions and enhance overall operational performance. As the industry continues to evolve, staying informed about market trends and advancements in differential pressure measurement technology will be essential for any professional involved in this field.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025