Nov . 07, 2024 13:35 Back to list

Differential Pressure Gauge Solutions for Industrial Applications in Perth

Exploring Differential Pressure Gauges in Perth A Comprehensive Overview

In the vibrant industrial landscape of Perth, understanding various instrumentation tools is crucial for ensuring operational efficiency and safety. Among these tools, the differential pressure gauge plays a pivotal role across various industries, including manufacturing, water treatment, and HVAC systems. This article delves into the importance, applications, and selection of differential pressure gauges, specifically within the context of Perth’s industries.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. It typically consists of two pressure sensors connected to a single display. This gauge is essential for processes where pressure differentials indicate system performance or operational safety. For example, it can monitor the pressure drop across a filter to determine when maintenance is required, ensuring optimal operation.

Importance of Differential Pressure Measurement

In an industrial setting, maintaining the correct pressure levels is crucial for operational efficiency. A differential pressure gauge helps in identifying blockages, leaks, or other issues within a system. For industries like oil and gas, water treatment, and chemical processing prevalent in Perth, precise pressure measurement can mean the difference between smooth operations and costly downtime.

Moreover, safety is paramount. Over-pressurization can lead to catastrophic failures, while under-pressurization can result in inadequate performance. Differential pressure gauges provide real-time data that can help operators make informed decisions to maintain safe operating conditions.

Applications in Industry

1. HVAC Systems In Perth’s hot climate, HVAC systems are vital for both residential and commercial buildings. Differential pressure gauges help regulate airflow and ensure that the heating and cooling systems operate efficiently. By measuring the pressure difference across filters, technicians can determine when to clean or replace air filters, maintaining indoor air quality and energy efficiency.

2. Water Treatment The water treatment industry plays a significant role in Perth's infrastructure. Differential pressure gauges are essential in monitoring the pressure drop across membrane filters and sedimentation tanks. This information is critical for maintaining water quality and ensuring compliance with environmental regulations.

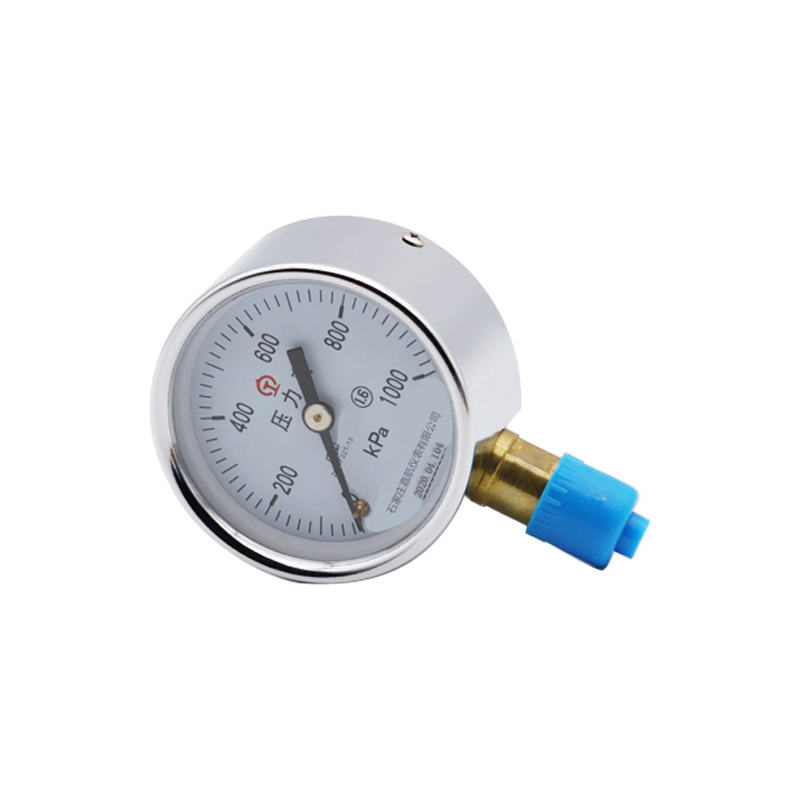

differential pressure gauge perth

3. Oil and Gas With Australia being a significant player in the oil and gas sector, monitoring pressure in pipelines and processing equipment is vital. Differential pressure measurement helps in leak detection, ensuring that any potential issue is addressed before it escalates.

4. Pharmaceuticals In the pharmaceutical industry, maintaining sterile conditions is crucial. Differential pressure gauges are used in cleanrooms to monitor pressure differentials, ensuring contamination-free environments for drug manufacturing.

Choosing the Right Differential Pressure Gauge

When selecting a differential pressure gauge for specific applications in Perth, several factors should be considered

1. Range and Accuracy Choose a gauge with the appropriate pressure range and accuracy for the specific application. For instance, very low-pressure applications require highly sensitive gauges.

2. Material Compatibility The construction material of the gauge must be compatible with the mediums being measured to prevent corrosion or damage.

3. Environment Consider the environmental conditions where the gauge will be installed. Factors such as temperature, humidity, and potential exposure to chemicals can influence the choice of a gauge.

4. Type of Installation Different gauges may require different installation protocols. Ensure that the selected gauge can be installed in the intended location without obstructing other equipment.

Conclusion

As Perth continues to grow as a hub for various industries, the significance of differential pressure gauges cannot be understated. They serve as vital tools in ensuring safety, efficiency, and compliance with regulations across multiple sectors. By understanding their function and applications, industries in Perth can enhance their operational reliability and contribute to a sustainable future. Investing in quality differential pressure gauges is not just a matter of compliance but a commitment to excellence in industrial practices.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025