Nov . 19, 2024 05:24 Back to list

differential pressure gauge factory jah

Understanding Differential Pressure Gauges A Crucial Tool in Various Industries

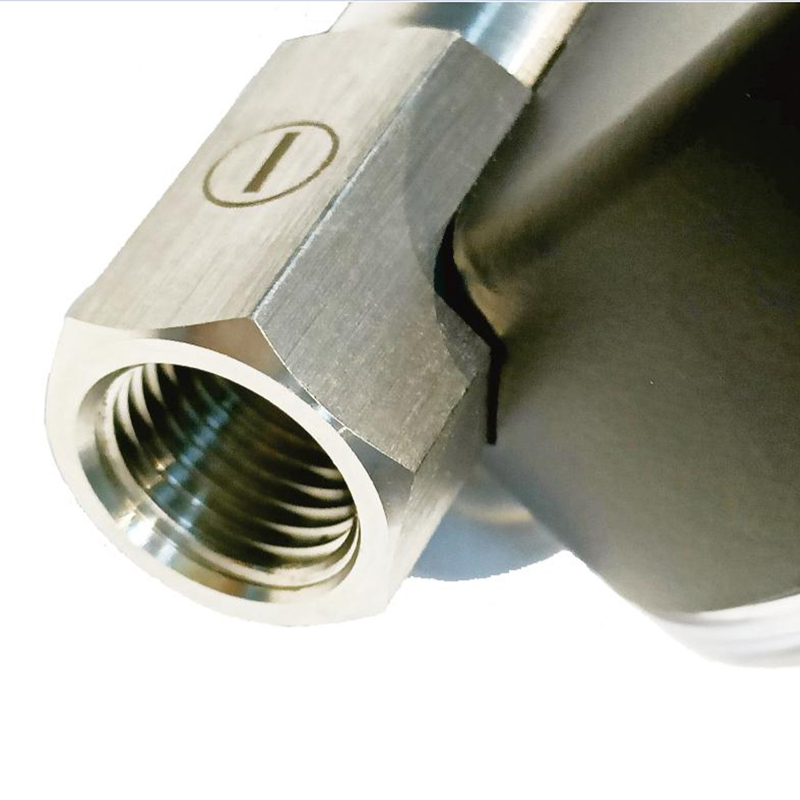

Differential pressure gauges are essential instruments in many industrial applications, allowing for accurate measurement of pressure differences in various systems. These devices play a pivotal role in monitoring and controlling processes in industries such as oil and gas, chemical manufacturing, pharmaceuticals, and water treatment. In this article, we will explore the importance of differential pressure gauges, how they work, and their applications, particularly focusing on the innovative offerings from Jah, a reputable factory in this field.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This measurement is critical in understanding how fluids move through pipelines, the performance of filtration systems, and the integrity of various processes. The gauge provides a visual representation of pressure differences, allowing operators to make informed decisions based on real-time data.

How Does a Differential Pressure Gauge Work?

The basic principle behind a differential pressure gauge relies on the use of two pressure sensing elements that are connected to a single display. The gauge calculates the difference in pressure between these two sensing elements, which usually are connected to two different points in a system. The most common types of differential pressure gauges include liquid-filled gauges and mechanical gauges, each with its unique operational mechanisms.

In a liquid-filled differential pressure gauge, for instance, the gauge is filled with a fluid that transmits the pressure changes to a dial that shows the differential reading. On the other hand, mechanical gauges may utilize a diaphragm or a Bourdon tube to measure pressure differences, translating the movement into a readable format.

Applications of Differential Pressure Gauges

1. Filtration Systems In filtration processes, maintaining the correct pressure difference is crucial to ensuring efficient operation. Differential pressure gauges help operators monitor the load on filters, indicating when they need maintenance or replacement to prevent system failure.

differential pressure gauge factory jah

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) applications, differential pressure gauges measure the pressure drop across filters, helping in maintaining optimal air flow and system efficiency.

3. Chemical Processing Accurate measurement of pressure differentials is vital in chemical processing to maintain safety standards and operational efficiency. Differential pressure gauges assist in monitoring pressure drops across reactors and separators.

4. Water Treatment In water treatment facilities, these gauges help monitor the filtration processes, ensuring that contaminants are effectively removed and quality standards are met.

The Jah Advantage

Jah, a well-established factory specializing in the manufacturing of differential pressure gauges, stands out for its commitment to quality and innovation. Their products are designed with precision, ensuring reliability and accuracy in every application. Jah’s differential pressure gauges are engineered to withstand harsh conditions, making them suitable for various environments. With a focus on customer satisfaction, Jah provides tailored solutions to meet the specific needs of different industries.

Moreover, Jah integrates cutting-edge technology into its manufacturing process, resulting in gauges that not only perform exceptionally well but are also user-friendly. The company's emphasis on research and development ensures that their products remain at the forefront of industry standards.

Conclusion

In conclusion, differential pressure gauges are indispensable tools in many industrial sectors, providing critical data that influences operational efficiency and safety. With manufacturers like Jah leading the way in innovation and quality, companies can confidently harness the power of these instruments to enhance their processes. As industries continue to evolve and adopt more complex systems, the role of differential pressure gauges will become even more vital. By understanding and implementing these devices, businesses can not only optimize their operations but also ensure compliance with safety standards, ultimately leading to enhanced productivity and profitability.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025