Oct . 18, 2024 13:12 Back to list

Digital Suppliers for Differential Pressure Gauge Solutions and Equipment

Understanding Differential Pressure Gauge Digital Suppliers

In various industrial applications, the measurement of pressure differences is crucial for ensuring system efficiency, safety, and reliability. Differential pressure gauges, particularly digital models, are essential tools in this regard. These instruments are employed across several sectors, including HVAC, water treatment, pharmaceuticals, and oil and gas. With the growing demand for accurate and reliable pressure measurement, the role of digital differential pressure gauge suppliers has become increasingly significant.

What is a Differential Pressure Gauge?

A differential pressure gauge compares the pressure of two different points within a system, providing a measure of the difference. This measurement is vital in understanding how fluids move through pipes, filters, and other equipment. Digital differential pressure gauges offer enhanced functionality compared to their analog counterparts. They provide more precise readings, better readability due to digital displays, and often include features like data logging and communication capabilities.

Importance of Digital Technology

Digital differential pressure gauges offer several advantages over traditional mechanical gauges. Firstly, their precision is paramount in industries where small discrepancies can lead to significant operational issues. Digital gauges often utilize advanced sensors that can detect minute changes in pressure. Additionally, these devices frequently come equipped with features that allow users to set alarm thresholds, enabling immediate alerts when pressures exceed predefined limits.

Moreover, many digital models support connectivity options such as I2C, RS232, or Modbus, allowing integration with broader control systems. This capability is particularly useful in modern smart manufacturing environments where data collection, monitoring, and analysis are foundational components of operational strategies.

The Role of Suppliers

Digital differential pressure gauge suppliers are tasked with selecting and distributing products that meet industry standards. They play a crucial role in guiding customers toward the best-suited instruments for their specific applications. When choosing a supplier, several factors should be considered

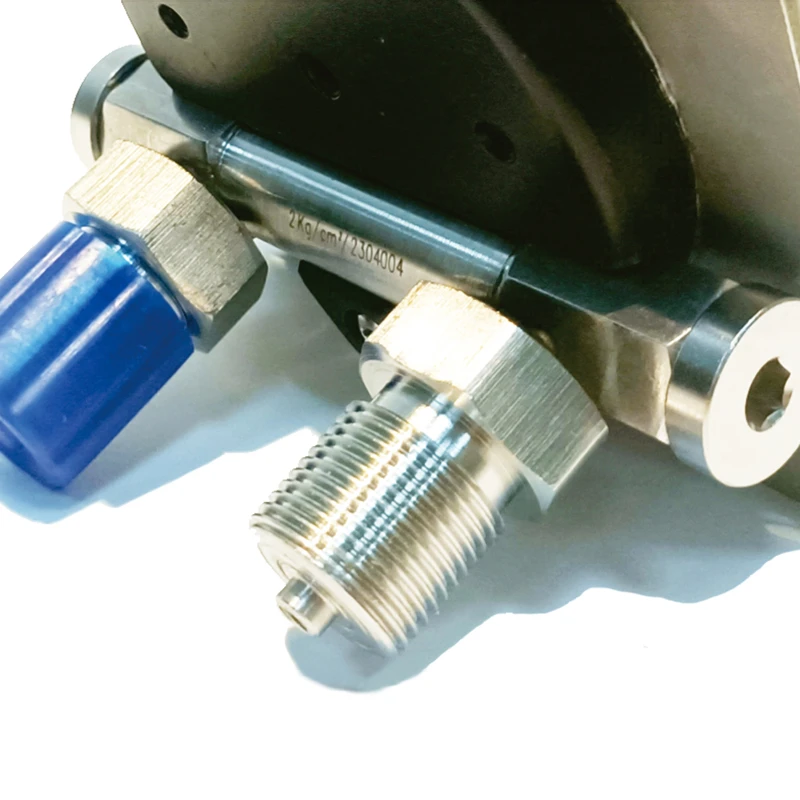

differential pressure gauge digital suppliers

1. Product Range and Specifications A reliable supplier should offer a broad range of differential pressure gauges, catering to diverse industries and requirements. The specifications should reflect various measurement ranges, accuracy levels, and certifications.

2. Quality Assurance Suppliers must ensure that their products meet the necessary quality standards. This includes certifications such as ISO, which guarantees that the gauges are manufactured in accordance with international quality regulations.

3. Technical Support and Services Post-purchase support is vital for the implementation and maintenance of pressure gauges. The supplier should provide comprehensive technical assistance, including installation help, troubleshooting, and calibration services.

4. Competitive Pricing While quality is paramount, suppliers also need to offer competitive pricing. Businesses often operate under tight budgets, making cost-effective solutions a significant factor in purchasing decisions.

5. Reputation and Reviews Researching a supplier's reputation is essential. Client testimonials and industry reviews can provide insight into a supplier's reliability, product quality, and customer service.

Applications of Digital Differential Pressure Gauges

These gauges are critical in various applications. In HVAC systems, they measure pressure drops across filters and coils, ensuring optimal airflow and system efficiency. In the pharmaceutical industry, they monitor processes to maintain sterile conditions by ensuring that differential pressure between rooms is controlled. Additionally, in the oil and gas sector, they help monitor pipeline integrity, ensuring that pressure differences do not exceed safe thresholds.

Conclusion

As industries continue to evolve towards automation and high-precision measurement systems, the role of digital differential pressure gauge suppliers will only grow more pivotal. By providing reliable instruments that enhance system performance and safety, these suppliers contribute to the operational excellence of various sectors. Understanding the value and functionality of these gauges is essential for any business that relies on fluid dynamics, pressure control, and the optimization of operational processes. Choosing the right supplier ultimately paves the way for improved performance, better safety, and enhanced productivity in industrial applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025