Oct . 12, 2024 16:50 Back to list

differential pressure gauge diaphragm type service

Understanding Differential Pressure Gauge Diaphragm Type Service

Differential pressure gauges are essential instruments used in various industrial applications to measure the pressure difference between two points in a system. One of the most commonly utilized designs for these gauges is the diaphragm type. This article will explore the principles behind diaphragm-type differential pressure gauges, their specifications, applications, and maintenance considerations to ensure accurate and reliable performance in service.

Principles of Operation

A diaphragm-type differential pressure gauge operates on the principle of a flexible diaphragm that separates two chambers. Each chamber is connected to a different pressure source, allowing the diaphragm to flex according to the pressure difference across it. This deflection is translated into a mechanical movement that drives a pointer on a dial indicating the differential pressure.

When pressure is applied to one side of the diaphragm, it deforms in response, allowing the gauge to accurately measure the difference in pressure. The measurement is typically displayed in units such as psi, bar, or Pascal, depending on the industry and application requirements.

Key Specifications

When choosing a diaphragm-type differential pressure gauge, several key specifications must be considered

1. Range The gauge should have a suitable pressure range according to the application. Different designs are available to accommodate low, medium, and high-pressure differentials.

2. Material The diaphragm material is crucial as it must be compatible with the fluid being measured. Common materials include stainless steel, silicon, and various elastomers that provide resistance to corrosion, high temperature, and other environmental factors.

3. Accuracy This specification defines how closely the gauge's readings reflect actual pressure differences. Accuracy can vary between gauges; therefore, it is essential to select one with adequate precision for the specific application.

4. Overpressure Protection Some applications may involve pressure spikes. Selecting a gauge with overpressure protection helps prevent damage and ensures longevity.

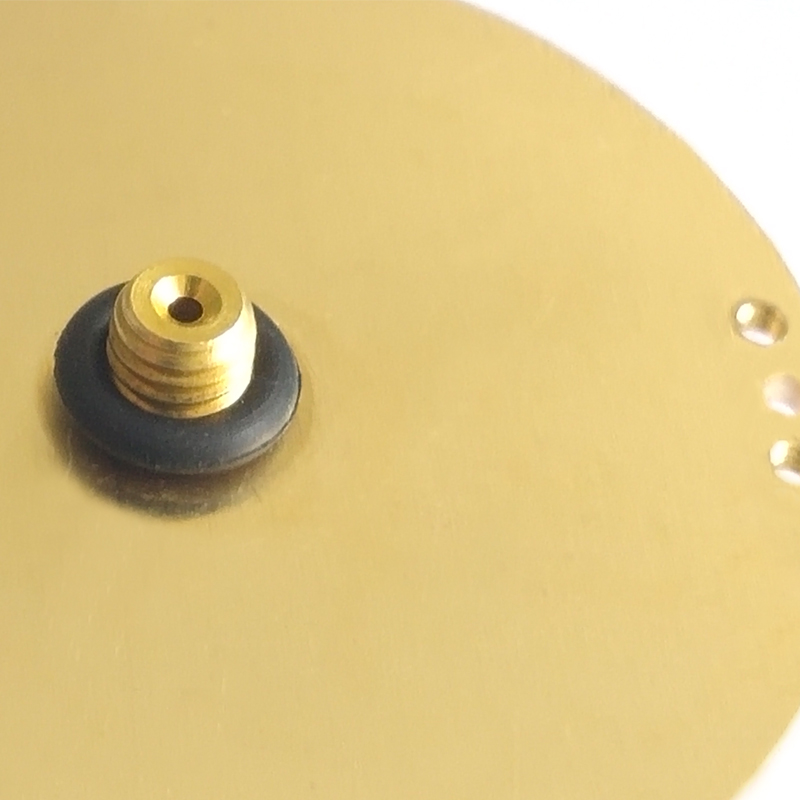

5. Connections Check the type of connections required for installation—flanged, threaded, or sanitary connections, depending on the industry standards and the installation environment.

Applications

differential pressure gauge diaphragm type service

Diaphragm-type differential pressure gauges are widely used across various industries

- Process Industries These gauges are often used to monitor flow rates in pipelines, measure air pressures in HVAC systems, and track filter conditions in water treatment plants.

- Oil and Gas Monitoring pressure differentials in drilling operations or processing units is critical for safety and efficiency. Diaphragm-type gauges play a key role in detecting pressure drops in pipelines and equipment.

- Pharmaceuticals In the pharmaceutical industry, maintaining sterile environments is crucial. These gauges monitor pressure differentials in cleanrooms and sterile processing areas to ensure compliance with regulatory standards.

- HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges are used to monitor filter conditions and system performance, ensuring efficient operation and energy savings.

Maintenance Considerations

To maintain the accuracy and reliability of diaphragm-type differential pressure gauges, regular maintenance is essential

1. Calibration Periodic calibration against pressure standards is crucial to ensure precision and mitigate drift over time.

2. Inspection Regular visual inspections can identify signs of wear, damage, or corrosion that could affect performance.

3. Cleaning Contamination can hinder gauge functionality. Cleaning the diaphragm and ensuring proper installation can help maintain accuracy.

4. Documentation Keeping records of maintenance actions and calibrations provides valuable data for audits and process improvements.

Conclusion

Diaphragm-type differential pressure gauges are indispensable tools for measuring pressure differences in various applications. Their reliability, accurate performance, and versatility make them a favored choice across multiple industries. By understanding their principles of operation, specifications, applications, and maintenance needs, engineers and technicians can ensure the long-term functionality and precision of these essential instruments. Proper selection, installation, and maintenance are key to unlocking the full potential of diaphragm-type differential pressure gauges in service.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025