Dec . 06, 2024 05:21 Back to list

differential pressure gauge bourdon tube service

Understanding the Differential Pressure Gauge with Bourdon Tube Technology

Differential pressure gauges are essential instruments widely used in various industries to measure the difference in pressure between two points in a system. One of the most prevalent technologies used in these gauges is the Bourdon tube principle, which provides reliable and accurate readings.

How Differential Pressure Gauges Work

Differential pressure gauges operate by detecting the difference in pressure between two different points. This is essential in processes such as filtration, where it is important to monitor the pressure drop across a filter to determine when it needs to be replaced. The gauge consists of two pressure ports—one connected to the high-pressure side and the other to the low-pressure side.

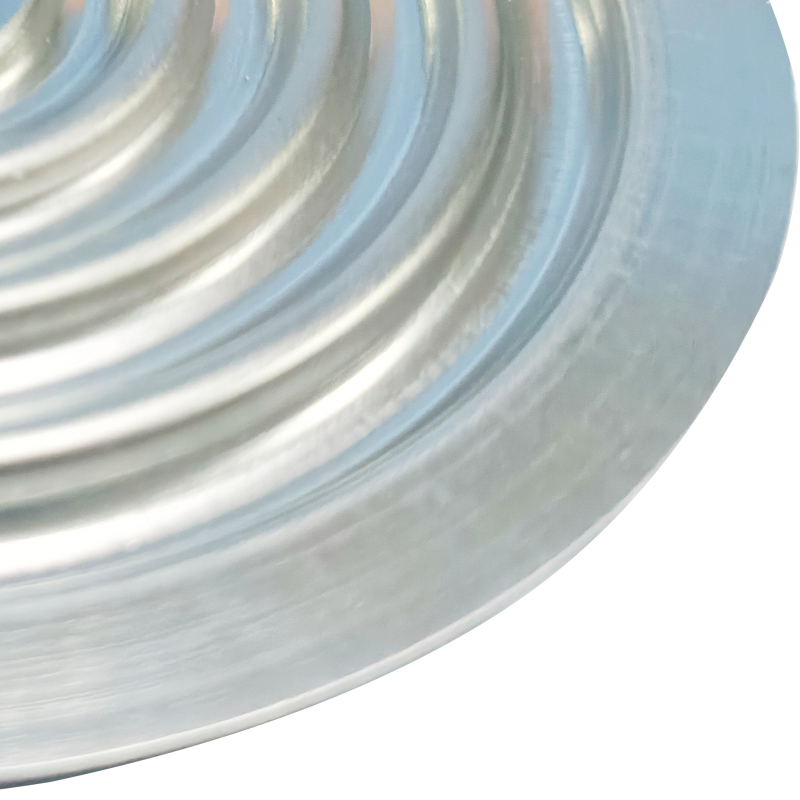

When the pressure differential exists, it causes the Bourdon tube, a coiled metal tube, to deform. The amount of deformation of the tube is proportional to the pressure difference. As the tube attempts to straighten under increased pressure, this movement is transferred to a pointer on a dial, providing a clear visual representation of the pressure differential.

The Bourdon Tube A Mechanical Marvel

The Bourdon tube is crafted from materials such as brass, stainless steel, or other alloys that can withstand both high pressures and corrosive environments. Its unique coiled design allows for high sensitivity and resilience, making it suitable for various applications.

When choosing a differential pressure gauge, the material of the Bourdon tube is crucial, especially for environments where chemical exposure is likely. The choice of materials directly influences the gauge's resistance to corrosion and extends its service life, which is a vital consideration for maintenance and operation costs.

Calibration and Accuracy

differential pressure gauge bourdon tube service

To ensure accurate measurements, differential pressure gauges must be calibrated regularly. Calibration involves comparing the gauge's readings with a known standard and adjusting as necessary. This process is essential, as erroneous readings can lead to significant operational issues, particularly in applications involving critical processes such as pharmaceuticals or food manufacturing.

Calibration frequency may depend on the application, environment, and regulations governing the industry. Regular maintenance can help identify issues before they lead to serious failures, thus ensuring consistent performance over time.

Applications

Differential pressure gauges are found in various applications across multiple industries, including

1. Oil and Gas Monitoring pressure drops across filters and separators. 2. Pharmaceuticals Ensuring the correct operating conditions in production lines. 3. HVAC Systems Assessing air filter conditions and duct pressure variations. 4. Water Treatment Tracking the pressure drop across membranes and filters.

By providing a straightforward and reliable way to measure pressure differentials, Bourdon tube gauges play a crucial role in maintaining system efficiency and safety.

Conclusion

In summary, differential pressure gauges utilizing Bourdon tube technology are indispensable across various industries for their reliability, sensitivity, and accuracy. Understanding their function, selecting the right materials, ensuring regular calibration, and knowing their applications can significantly enhance operational efficiency and safety. As industries continue to evolve, these gauges will undoubtedly remain a cornerstone of process measurement and control, contributing to various applications that demand precision and reliability.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025