Oct . 21, 2024 00:24 Back to list

Cost Estimates for Differential Pressure Gauge Assembly Components and Installation

Understanding Differential Pressure Gauge Assembly Quotes and Insights

In the realm of engineering and instrumentation, the differential pressure gauge assembly plays a crucial role in various applications. These gauges are designed to measure the difference in pressure between two points in a system, allowing for accurate monitoring and control. As industries strive for efficiency and precision, the significance of these instruments cannot be overstated. Let’s delve deeper into the key aspects of differential pressure gauge assemblies, supported by insightful quotes from industry experts and pioneers.

Differential pressure gauges are essential in numerous fields such as oil and gas, pharmaceuticals, water treatment, and HVAC systems. The ability to monitor pressure differences helps in identifying flow rates, detecting blockages, and ensuring optimal operating conditions. As Dr. Sarah Holloway, a renowned engineer, aptly states, “Instruments like differential pressure gauges are the lifelines of our industrial operations; they provide real-time data that can prevent disasters.”

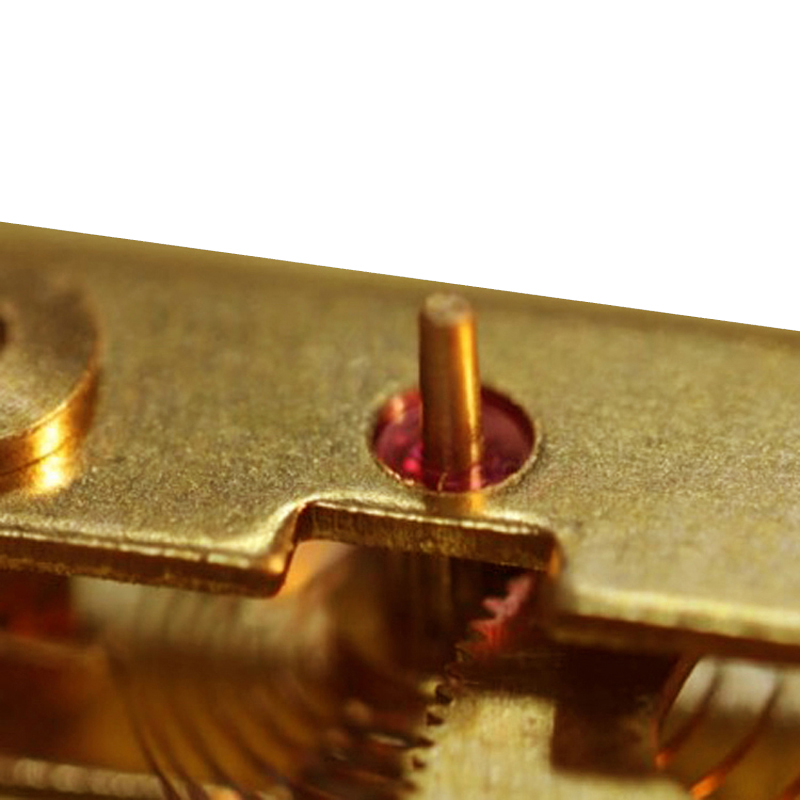

The assembly of a differential pressure gauge typically includes various components the sensing element, transmission line, display, and calibration mechanisms. Each part is integral to the functionality of the gauge. The sensing element, often a diaphragm or piezoelectric sensor, directly interacts with the pressure fields. As John Peters, a instrumentation specialist, mentions, “The quality of the sensing element dictates the accuracy and reliability of the entire gauge assembly.”

When choosing a differential pressure gauge assembly, professionals must consider the application requirements and environmental conditions. Different industries may necessitate specific materials and designs to withstand challenging conditions, such as high temperatures or corrosive substances. As quoted by Anna Kim, an industry advisor, “Customization in differential pressure gauge assemblies is not just an option; it’s a necessity for ensuring performance in diverse applications.”

differential pressure gauge assembly quotes

Installation and maintenance of these gauges are pivotal to their longevity and effectiveness. Regular calibration and thorough checks are essential to ensure that the readings are accurate over time. Richard Eldridge, a maintenance expert, emphasizes this point “A well-maintained differential pressure gauge can be the difference between smooth operations and unexpected downtime.” His insight highlights the importance of proactive measures in managing these critical instruments.

Moreover, technological advancements have led to the development of digital differential pressure gauges, which offer enhanced features such as data logging, remote monitoring, and integration with control systems. These innovations represent a significant leap forward in instrument technology. As Professor Jane Loughlin points out, “Adapting to digital solutions provides not only greater precision but also deeper insights into operational efficiency.”

The sustainability aspect of differential pressure gauge assemblies is gaining traction as industries focus on reducing their environmental footprint. The ability to monitor and optimize resource usage through accurate pressure measurements is crucial in achieving sustainability goals. Environmental engineer Tim Lawson states, “Efficient pressure monitoring is foundational to creating sustainable industrial practices; it paves the way for reducing waste and improving resource management.”

In conclusion, the differential pressure gauge assembly is an indispensable component across numerous industries, providing essential data for safe and efficient operations. The insights from experts underscore the importance of accuracy, maintenance, customization, and technological advancements in the realm of pressure measurement. As we continue to innovate and improve these instruments, the future of differential pressure measurement looks promising, corresponding with the ongoing trends of automation and sustainability. Understanding, investing in, and maintaining these assemblies will undoubtedly lead to enhanced performance and safety in various applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025