Nov . 16, 2024 02:22 Back to list

differential pressure gauge assembly product

Understanding Differential Pressure Gauge Assembly Applications and Importance

Differential pressure gauges are vital instruments widely used across various industries to measure pressure differences between two points in a system. They play a crucial role in maintaining system efficiency, safety, and performance. In this article, we will explore the components, functioning, and significance of differential pressure gauge assembly in multiple applications.

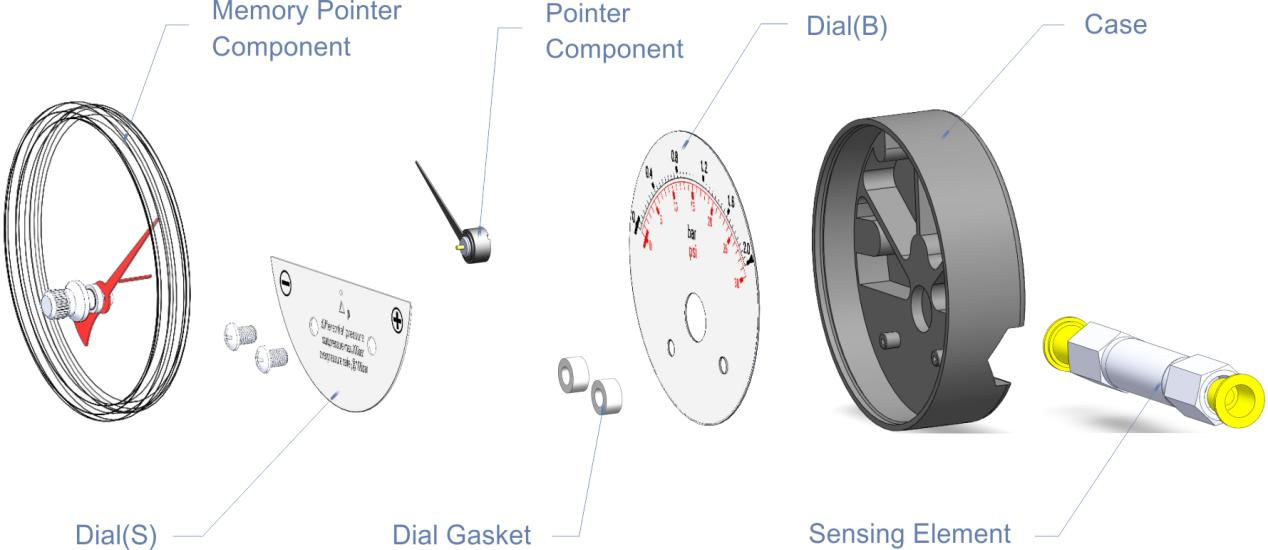

Components of Differential Pressure Gauge Assembly

A typical differential pressure gauge assembly consists of several key components. The primary elements include

1. Sensing Elements These are usually diaphragm or capsule-based sensors that respond to pressure differences. When pressure is applied, they deform, generating a mechanical movement that can be translated into a reading.

2. Pressure Ports The assembly contains two ports – one for the high-pressure side and another for the low-pressure side. The pressure difference between these ports enables the measurement.

3. Transmission Mechanism This component converts the mechanical movement from the sensing elements into a readable format. Common mechanisms include levers, gears, or electronic transducers that transform mechanical movements into electrical signals.

4. Display Unit The display can be analog (like a dial gauge) or digital. Digital displays are often equipped with advanced features, including data logging and remote monitoring capabilities.

5. Housing The casing protects the internal components from environmental factors such as dust, moisture, and corrosive substances, ensuring longevity and reliability.

Working Principle

The working principle of a differential pressure gauge is relatively straightforward. When the gauge is installed in a system, the high-pressure side receives pressure from the source, while the low-pressure side draws from another point in the system. The gauge measures the difference in pressure, and this value is displayed on the meter.

For example, in a filtration system, a differential pressure gauge can help determine when a filter is clogged, indicating the need for maintenance or replacement

. Here, the pressure drop across the filter is measured, guiding operators in maintaining optimal filtration efficiency.differential pressure gauge assembly product

Applications of Differential Pressure Gauges

Differential pressure gauges find applications in various sectors

1. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor airflow and filter conditions, ensuring efficient operation and air quality.

2. Chemical Processing In chemical plants, differential pressure gauges assist in monitoring processes and maintaining safety. They provide crucial data regarding flow rates and system pressure that prevent hazardous situations.

3. Water and Wastewater Treatment These gauges help monitor levels in tanks and pressure in pipelines, ensuring operational efficiency and compliance with environmental regulations.

4. Oil and Gas Industry Differential pressure gauges are used to measure flow rates in pipelines and monitor conditions in drilling operations, playing a vital role in ensuring safety and efficiency.

5. Pharmaceuticals In this sector, stringent regulations require precise monitoring of processes. Differential pressure gauges help maintain sterile environments and monitor filtration systems critical for product safety.

Importance of Differential Pressure Measurement

Measuring differential pressure contributes significantly to process control, ensuring that systems operate within safe and efficient parameters. Accurate readings can prevent equipment failure, reduce downtime, and minimize maintenance costs. Moreover, they are essential for compliance with industry regulations by ensuring optimal operational conditions are met.

Furthermore, advancements in technology have led to the development of smart differential pressure gauges equipped with IoT capabilities. These devices provide real-time monitoring and data analytics, enabling predictive maintenance and enhancing overall operational efficiency.

Conclusion

Differential pressure gauge assembly is an essential component in various industrial applications. By accurately measuring pressure differences, these gauges help maintain system efficiency, ensure safety, and reduce operational costs. As technology evolves, so will the capabilities of these gauges, paving the way for smarter and more efficient monitoring solutions in the future. Understanding their functionality and significance is indispensable for professionals in various fields, from engineering to facility management.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025