Nov . 16, 2024 21:33 Back to list

Differential Pressure Gauge for 1/4 FNPT Applications and Services

Understanding Differential Pressure Gauge Services for Process Control

In various industrial applications, monitoring and controlling process variables is paramount for maintaining operational efficiency and safety. One essential instrument used for this purpose is the differential pressure gauge, specifically models such as the 1-4 FNPT service gauges. Understanding the functionality, applications, and advantages of these devices is crucial for engineers and technicians alike.

Differential pressure gauges are designed to measure the difference in pressure between two points within a system. This measurement is critical in processes such as filtration, level measurement, and flow monitoring. The gauges are typically equipped with two pressure ports one connected to the higher pressure side and the other to the lower pressure side. The gauge then displays the difference, allowing operators to assess the process conditions effectively.

The designation 1-4 FNPT refers to the size and type of the connection ports. FNPT stands for Female National Pipe Thread, indicating a standardized thread type commonly used in piping systems. A size of 1-4 suggests that the gauge is designed to fit various piping configurations, making it versatile and widely applicable across different industries, including oil and gas, chemical manufacturing, and water treatment.

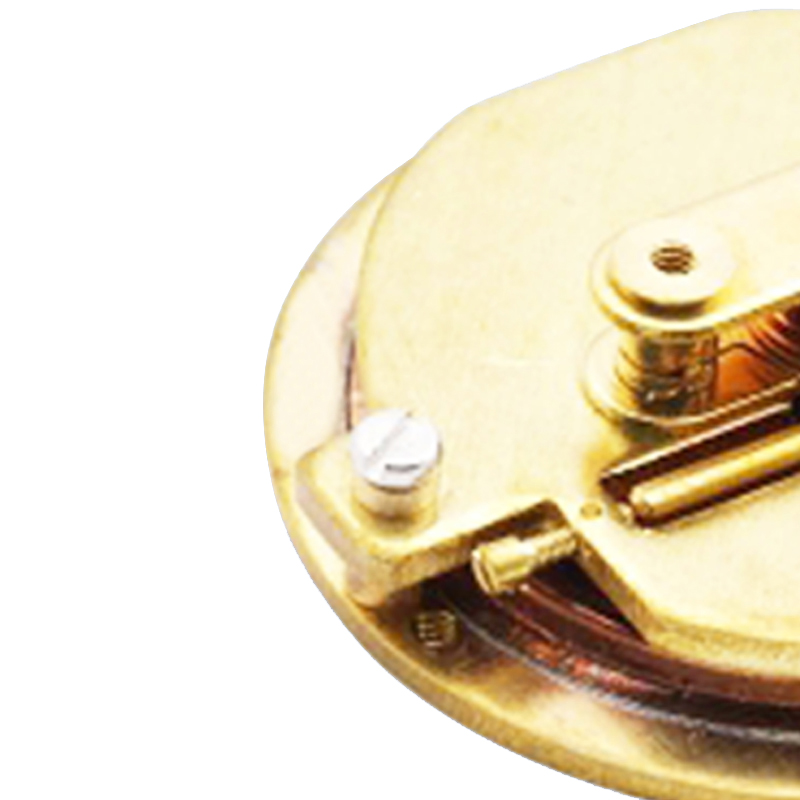

differential pressure gauge 1 4 fnpt service

One of the key benefits of using a differential pressure gauge is its role in safeguarding equipment and ensuring process integrity. For example, in filter applications, a sudden increase in differential pressure can indicate a clogged filter, requiring immediate attention to prevent system failure. By monitoring the differential pressure, operators can implement timely maintenance, reducing downtime and operational costs.

Moreover, differential pressure gauges are instrumental in level measurement within tanks and vessels. By measuring the pressure exerted by the liquid column, these gauges provide accurate level readings, essential for inventory management and preventing overflows.

The installation of a 1-4 FNPT differential pressure gauge is straightforward. Typically, it involves connecting the gauge to the designated pressure ports using appropriate fittings. It’s important to ensure that the gauge is calibrated for the specific media and pressure range to achieve the most accurate readings.

In summary, differential pressure gauges, especially the 1-4 FNPT service types, play a vital role in various industrial applications. Their ability to provide real-time data on pressure differences aids in optimizing process control, enhancing safety, and prolonging equipment lifespan. As industries increasingly prioritize efficiency and reliability, the importance of accurately monitoring differential pressure cannot be overstated. Investing in quality gauges and ensuring proper installation and maintenance will ultimately contribute to smoother operations and improved outcomes in any industrial setting.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025