Sep . 04, 2024 03:58 Back to list

differential pressure gauge accuracy factories

Understanding Differential Pressure Gauge Accuracy in Manufacturing

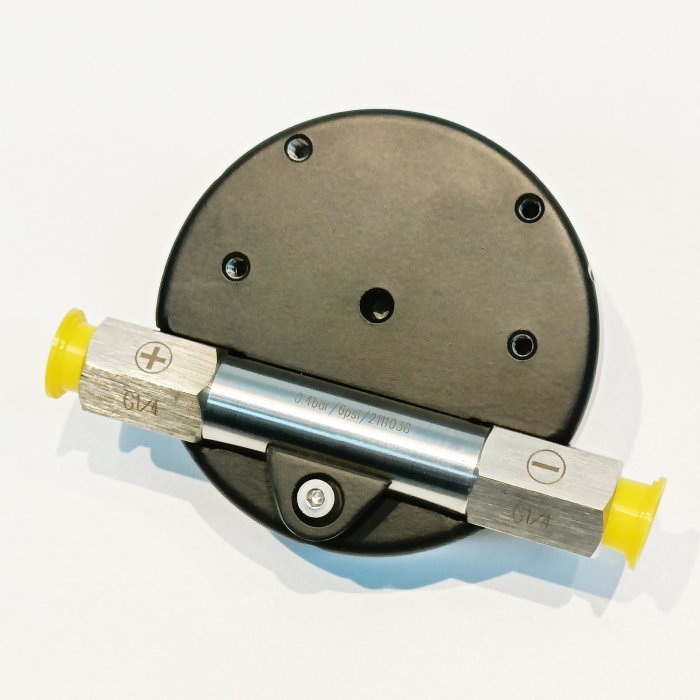

Differential pressure gauges are essential instruments used in various industries, from chemical processing to HVAC systems, to measure the difference in pressure between two points. The accuracy of these gauges is crucial, as it directly impacts process efficiency, safety, and regulatory compliance. Manufacturers of differential pressure gauges continuously strive to improve their products, emphasizing the importance of accuracy in their designs and operations.

One of the primary factors influencing gauge accuracy is the calibration process. Calibration involves comparing the gauge's output against a known standard or reference and adjusting it as necessary. Most reputable factories implement rigorous calibration procedures, often following national or international standards such as ISO 17025. Regular calibration checks help maintain the accuracy of the instruments throughout their operational life, ensuring that even minor drifts in readings are corrected promptly.

Temperature and environmental conditions are additional considerations that can affect the accuracy of differential pressure gauges. Many manufacturers utilize advanced materials and technologies to mitigate these effects. For instance, some gauges are designed with temperature compensation features that help maintain accurate readings despite fluctuations in ambient temperature. Furthermore, the physical design—such as the choice of diaphragm material or the use of protective casings—can enhance durability and reduce the likelihood of errors induced by harsh operational environments.

differential pressure gauge accuracy factories

The manufacturing process itself also plays a pivotal role in ensuring gauge accuracy. Factories often employ state-of-the-art machinery and adhere to strict quality control protocols during the production phase. Each component of the differential pressure gauge, from the sensor to the display, must be manufactured to exact specifications. By utilizing automated processes and quality assurance testing, manufacturers can significantly reduce the likelihood of defects that could compromise accuracy.

Another crucial aspect is the choice of technology used in differential pressure gauges. Analog gauges may offer simplicity and ease of use, but digital gauges often provide higher precision and more features, such as data logging and remote monitoring capabilities. Digital gauges can constantly update readings and store historical data, enabling operators to identify trends and anomalies in pressure differentials more effectively.

Moreover, manufacturers are increasingly investing in research and development to innovate new types of differential pressure gauges that provide enhanced accuracy and functionality. Emerging technologies, such as MEMS (Micro-Electro-Mechanical Systems), are paving the way for more compact and accurate devices that can be used in diverse applications.

In conclusion, the accuracy of differential pressure gauges is paramount for many industrial applications. Manufacturers focus on rigorous calibration, advanced materials, high-quality manufacturing processes, and innovative technologies to ensure that their gauges deliver reliable and precise measurements. As industries continue to evolve, the demand for accurate differential pressure gauges will remain crucial, driving further advancements in gauge technology and manufacturing practices.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025