Nov . 08, 2024 06:59 Back to list

Diaphragm-Based Pressure Measurement Solutions for Accurate Industrial Applications

Diaphragm Type Pressure Gauge An Essential Instrument for Industry

In various industrial applications, pressure measurement is critical for ensuring safety, efficiency, and functionality. Among the myriad types of pressure measurement devices available in the market, the diaphragm type pressure gauge stands out due to its unique construction and superior performance. This article delves into the fundamental aspects of diaphragm type pressure gauges, their advantages, typical applications, and popular manufacturers in the industry.

Understanding Diaphragm Type Pressure Gauges

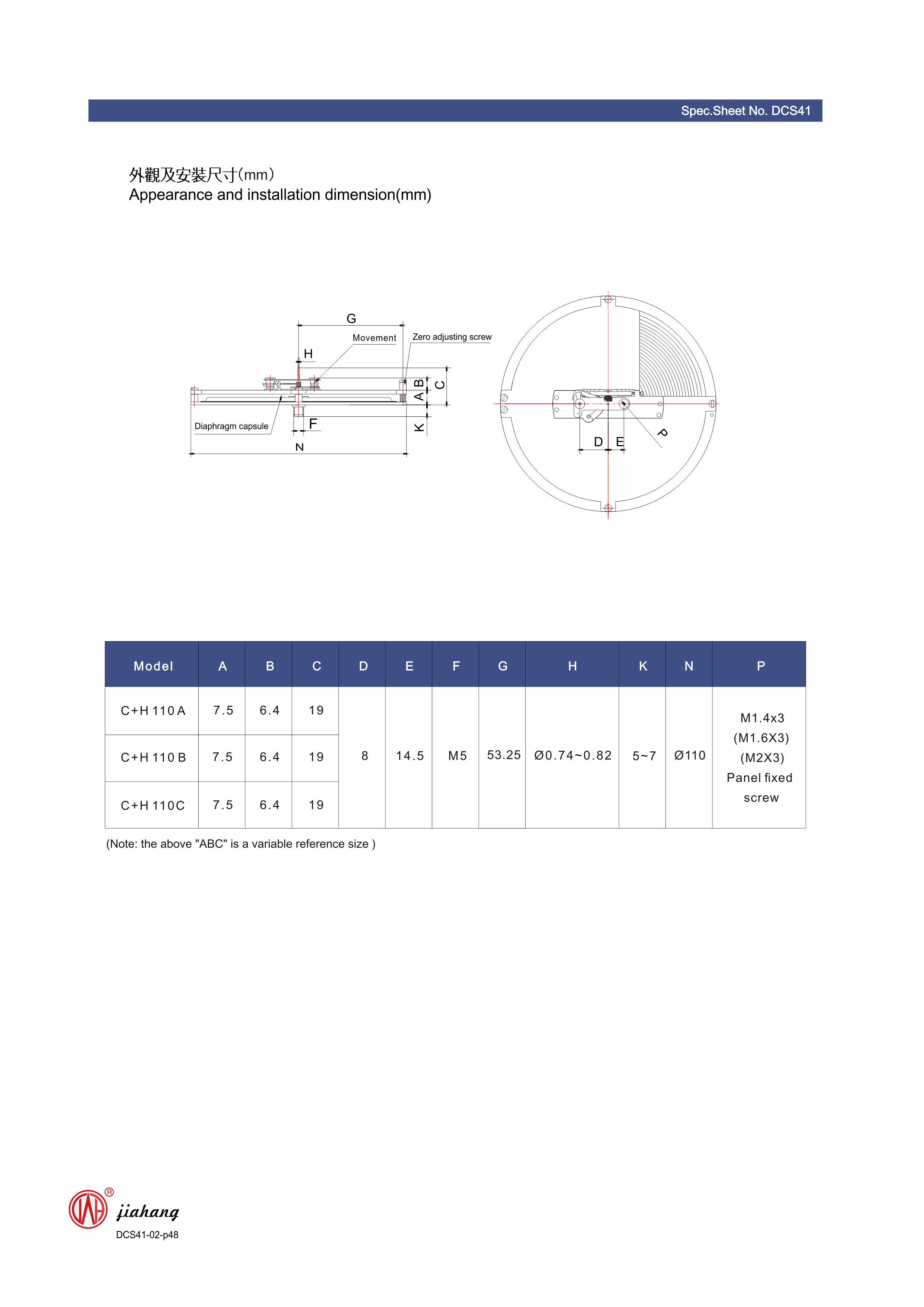

A diaphragm type pressure gauge operates on the principle of mechanical displacement. The core component of this gauge is a flexible diaphragm, typically made from materials such as stainless steel, which separates the pressure-sensing chamber from the gauge's internal mechanism. When pressure is applied, the diaphragm deforms, causing a mechanical displacement. This movement is then translated into a readable output on the gauge’s dial, indicating the pressure level.

Advantages of Diaphragm Type Pressure Gauges

One of the primary advantages of diaphragm type pressure gauges is their ability to measure low to medium pressures accurately. They are particularly effective in environments where volatile fluids or gases are present, as the diaphragm's design minimizes the risk of leakage. Furthermore, these gauges are renowned for their reliability and durability, which is essential for industrial applications that require consistent performance over extended periods.

Another significant benefit of diaphragm type gauges is their resistance to vibration and pulsation. In industries such as oil and gas, where equipment is often subject to harsh conditions, diaphragm gauges can provide stable readings without being affected by external vibrations. This ensures that operators receive accurate readings, leading to better decision-making and improved operational safety.

Typical Applications

diaphragm type pressure gauge company

Diaphragm type pressure gauges are widely used in a variety of industries, including oil and gas, chemical processing, food and beverage, and water treatment. In the oil and gas sector, they are employed to monitor pipeline pressure, ensuring that operations run smoothly and safely. In chemical processing, they measure the pressure of corrosive liquids and gases, providing critical data for maintaining safe operating conditions.

In the food and beverage industry, where hygiene and safety are paramount, diaphragm gauges are used to monitor pressure in processing systems without compromising the integrity of the products. Additionally, they play a vital role in water treatment facilities by measuring pressure in filtration systems, ensuring that systems operate efficiently and effectively.

Choosing the Right Manufacturer

When selecting a diaphragm type pressure gauge, choosing a reputable manufacturer is crucial. Many companies specialize in producing high-quality pressure measurement devices. Key players in the industry include WIKA, Ashcroft, and Omega Engineering. Each of these companies has established a track record of producing reliable and accurate gauges that meet the varying needs of different industries.

WIKA, for instance, is known for its extensive range of pressure measurement instruments, including diaphragm gauges that are designed for high performance in challenging environments. Ashcroft offers a variety of gauges that are suitable for both standard and customized applications, ensuring that customers can find the perfect solution for their needs. Meanwhile, Omega Engineering is recognized for its innovative approach to pressure measurement, incorporating advanced technologies into their gauge designs.

Conclusion

Diaphragm type pressure gauges are indispensable tools in modern industry, providing accurate and reliable pressure measurements across a spectrum of applications. Their robust design, resistance to adverse conditions, and adaptability make them the preferred choice among engineers and operators. As industries continue to evolve, the importance of precision measurement instruments like diaphragm type pressure gauges cannot be overstated. By choosing the right manufacturer and understanding the applications of these gauges, businesses can ensure operational efficiency and safety in their processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025