Dec . 16, 2024 08:01 Back to list

diaphragm seal pressure gauge wika suppliers

Understanding Diaphragm Seal Pressure Gauges A Focus on WIKA Suppliers

In industrial applications, accurate pressure measurement is vital for ensuring safety, efficiency, and reliability. One of the key instruments used for this purpose is the diaphragm seal pressure gauge. Among the leading manufacturers of these instruments is WIKA, a globally recognized supplier known for its high-quality measurement solutions. This article will explore the significance of diaphragm seal pressure gauges, specifically the innovative offerings from WIKA, their applications, advantages, and why selecting the right supplier is crucial.

What is a Diaphragm Seal Pressure Gauge?

A diaphragm seal pressure gauge is a type of pressure measurement device that employs a flexible diaphragm to separate the measuring element from the process fluid. This design is particularly advantageous when measuring corrosive, viscous, or high-purity fluids, as it prevents direct contact between the fluid and the measuring element, thus prolonging the lifespan of the gauge and ensuring accurate measurements.

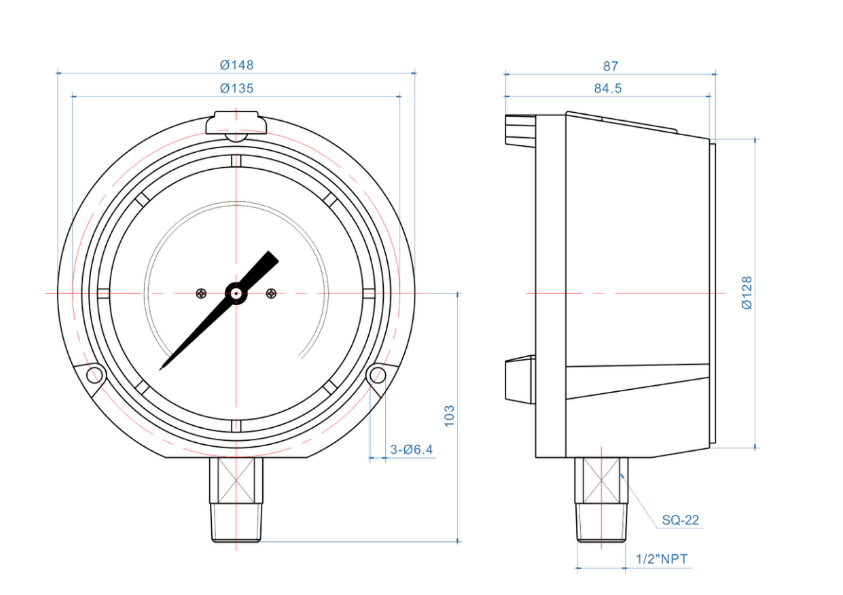

The construction of a diaphragm seal gauge typically involves a metal or elastomeric diaphragm that deforms under pressure, transmitting the force to a mechanical or electronic pressure sensing device. This results in the display of the pressure reading on a dial or digital screen.

Applications of Diaphragm Seal Pressure Gauges

Diaphragm seal pressure gauges find applications in various industries, including

1. Chemical Processing In environments where aggressive chemicals are present, diaphragm seals protect the measuring device from contamination and corrosion. 2. Food and Beverage Industry Ensuring product purity is critical; hence, these gauges prevent contamination while providing accurate pressure readings during processes such as pasteurization and bottling. 3. Pharmaceuticals In the pharmaceutical industry, maintaining the integrity of products is essential. Diaphragm seal gauges facilitate this by isolating the measuring device from potentially hazardous substances. 4. Oil and Gas This industry often involves extreme conditions, making diaphragm seal gauges ideal for measuring pressure in pipelines and during extraction processes.

diaphragm seal pressure gauge wika suppliers

Advantages of WIKA Diaphragm Seal Pressure Gauges

WIKA, with its extensive experience in production and innovation, provides several advantages when it comes to diaphragm seal pressure gauges

- Custom Solutions WIKA offers customized gauge solutions tailored to specific applications, ensuring compatibility with various media and environmental conditions. - High Precision and Reliability Their gauges are known for their accuracy and reliability, essential for maintaining operational efficiency in critical processes. - Durability Constructed from robust materials, WIKA diaphragm seal gauges are designed to withstand harsh conditions and prolonged use, making them a cost-effective solution in the long run. - Ease of Maintenance WIKA's designs emphasize ease of maintenance, which helps reduce downtime and operational costs.

Selecting the Right Supplier

When it comes to purchasing diaphragm seal pressure gauges, selecting the right supplier is crucial for ensuring product quality and performance. Here are a few considerations when choosing a supplier like WIKA

1. Reputation and Experience Look for suppliers with a proven track record in the industry. WIKA, founded in 1946, has established itself as a leader in measurement technology. 2. Technical Support and Services A good supplier should provide comprehensive technical support and services, including installation, calibration, and maintenance. 3. Product Range Ensure the supplier offers a diverse range of products to meet your specific needs, from standard models to highly specialized gauges. 4. Quality Assurance High-quality manufacturing processes and standards are imperative. WIKA operates under rigorous quality management systems to ensure that all products meet international standards.

Conclusion

Diaphragm seal pressure gauges are essential instruments in various industries, providing reliable and accurate pressure measurements while protecting against harsh process conditions. WIKA stands out as a leading supplier, renowned for its innovation, durability, and commitment to customer satisfaction. By choosing a reputable supplier, businesses can ensure they have the right instruments to maintain safety and efficiency in their operations. Whether in chemical processing, food production, or oil and gas exploration, diaphragm seal pressure gauges from WIKA can meet the diverse and demanding needs of modern industry.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025