Nov . 09, 2024 02:23 Back to list

WIKA Supplier for Diaphragm Seal Pressure Gauges and Related Products

Understanding Diaphragm Seal Pressure Gauges A Focus on WIKA Suppliers

In various industrial applications, accurate pressure measurement is crucial for ensuring the safety, efficiency, and longevity of equipment. One of the key instruments used for this purpose is the diaphragm seal pressure gauge. WIKA, a renowned manufacturer of pressure gauges and measuring instruments, offers an array of solutions that cater to different needs, particularly in demanding environments where conventional gauges might fail.

What is a Diaphragm Seal Pressure Gauge?

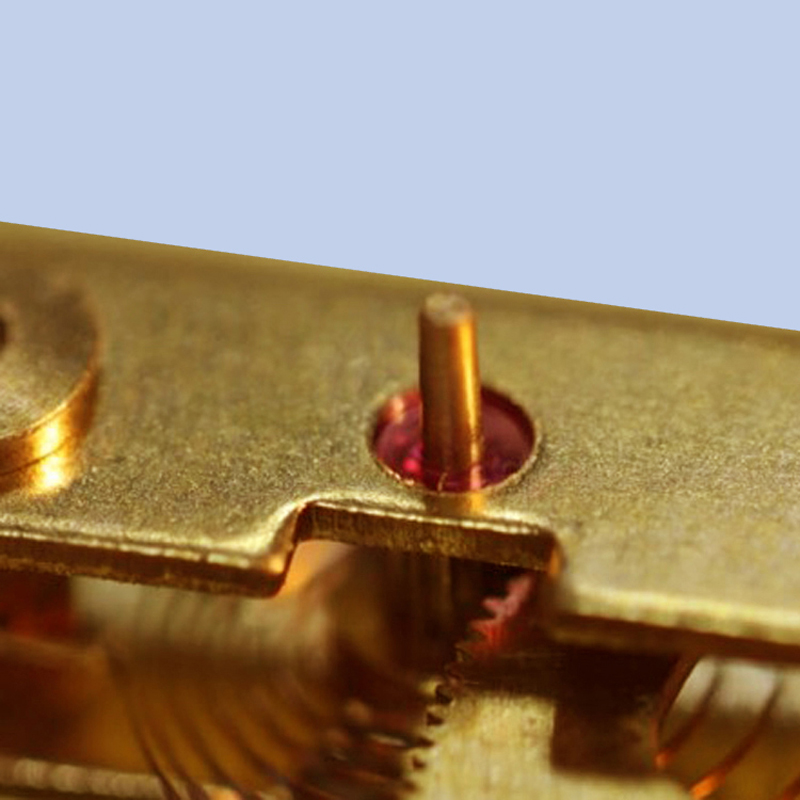

A diaphragm seal pressure gauge is specially designed to measure pressure while isolating the measuring element from the process media. This feature is essential in situations where the media can be corrosive, viscous, or contain solids, which could damage the internal components of a typical pressure gauge. The diaphragm acts as a barrier, allowing pressure to be transmitted to the gauge without direct contact between the media and the measuring instrument.

The diaphragm is usually made from materials such as stainless steel, Hastelloy, or Teflon, depending on the specific application and compatibility with the process media. The pressure acting on the diaphragm leads to a deformation that is then converted into an accurate pressure reading. This technology not only enhances the durability of the gauge but also ensures that the measurement remains reliable over time.

Advantages of WIKA Diaphragm Seal Pressure Gauges

WIKA's diaphragm seal pressure gauges come with several advantages that make them a preferred choice in numerous industries

1. Protection Against Corrosion The diaphragm seal prevents direct contact with the hazardous or corrosive media, greatly extending the lifespan of the measuring instrument.

2. Measurement of Viscous Fluids These gauges can effectively measure viscous liquids and slurries without clogging, which is a common challenge with standard gauges.

3. Accuracy and Reliability WIKA is known for its commitment to precision. Their diaphragm seal pressure gauges maintain high accuracy, even in fluctuating temperatures and pressures.

diaphragm seal pressure gauge wika supplier

4. Customization WIKA offers a variety of configurations to meet specific industry requirements. This includes options for different diaphragm materials, sizes, and connection types, allowing users to find the perfect fit for their application.

5. Ease of Installation Many of WIKA's diaphragm seal models are designed for straightforward installation, which can save time and labor costs in industrial settings.

Applications Across Industries

WIKA diaphragm seal pressure gauges are versatile and employed in various sectors, including

- Chemical Processing These gauges are essential in monitoring pressure in reactors, tanks, and pipelines, ensuring that operations remain within safe and efficient parameters.

- Food and Beverage In this industry, maintaining hygienic conditions is paramount. Diaphragm seals made from food-grade materials can safely measure pressure in production processes without contamination risks.

- Pharmaceuticals Precision is critical when dealing with sensitive compounds. WIKA's diaphragm seal pressure gauges support high standards of quality control.

- Oil and Gas Harsh conditions often necessitate robust instrumentation. WIKA gauges perform reliably in upstream and downstream operations, ensuring safe exploration and extraction processes.

Conclusion

The diaphragm seal pressure gauge is an essential tool in many industrial applications, providing a unique solution for measuring pressure in challenging environments. WIKA, as a leading supplier, offers a range of diaphragm seal pressure gauges designed to meet the needs of various industries with an emphasis on accuracy, reliability, and customization. For companies looking to enhance their measurement technology, selecting WIKA's products ensures that they are equipped with some of the best instruments available, thereby fostering safe and efficient operations. Whether for chemical processing, food production, or any other sector, WIKA’s diaphragm seal pressure gauges represent a sound investment in quality and performance.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025